A puller is a tool designed to remove tightly fitted parts such as gears, bearings, and pulleys, applying controlled force to extract components without damage. A separator, on the other hand, is specifically used to create space and separate two closely joined parts before removal, making it essential for tasks requiring delicate detachment.

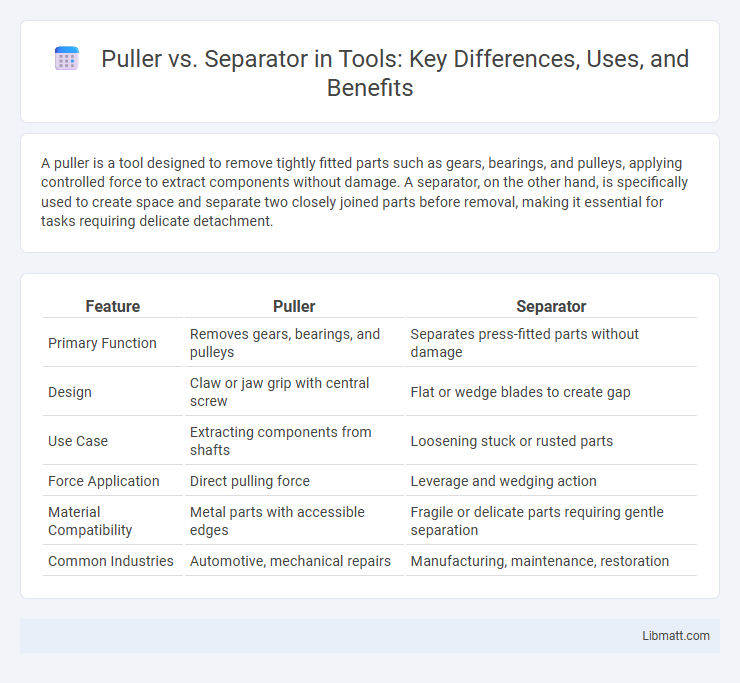

Table of Comparison

| Feature | Puller | Separator |

|---|---|---|

| Primary Function | Removes gears, bearings, and pulleys | Separates press-fitted parts without damage |

| Design | Claw or jaw grip with central screw | Flat or wedge blades to create gap |

| Use Case | Extracting components from shafts | Loosening stuck or rusted parts |

| Force Application | Direct pulling force | Leverage and wedging action |

| Material Compatibility | Metal parts with accessible edges | Fragile or delicate parts requiring gentle separation |

| Common Industries | Automotive, mechanical repairs | Manufacturing, maintenance, restoration |

Overview: Puller vs Separator

A puller is a mechanical tool designed to remove parts such as bearings, gears, or pulleys from a shaft by applying outward force, ensuring minimal damage to the components. A separator is a specialized device used to split or separate closely fitted parts, often by inserting a thin blade between them to create a gap for easier removal. While pullers focus on extraction through force, separators emphasize creating separation to facilitate disassembly in maintenance and repair tasks.

Definition and Core Functions

A puller is a mechanical tool designed to remove tightly fitted parts such as bearings, gears, and pulleys from a shaft by applying controlled force. A separator, on the other hand, is a specialized tool used to create a gap between two components, facilitating the removal of parts that are pressed or wedged together. Both tools play crucial roles in maintenance and repair tasks, ensuring efficient disassembly without causing damage to the components.

Key Differences

Pullers are mechanical tools designed to remove parts such as bearings, gears, or pulleys from shafts by applying force, while separators specifically create space between joined components allowing easier removal without damage. Pullers typically use jaws or arms to grip and extract parts directly, whereas separators use a wedge-shaped design to slip between tight fits, minimizing the risk of deformation. The choice between a puller and a separator depends on the component's size, fit type, and the required precision in disassembly tasks.

Types of Pullers and Separators

Mechanical pullers include two-jaw, three-jaw, and hydraulic types designed for removing gears, bearings, and pulleys with minimal damage. Separators, often used in tight spaces, come in plate and wedge configurations to split components by applying controlled force between mating parts. Both tools vary in size and capacity, catering to different industrial and automotive applications for efficient disassembly.

Common Applications

Pullers and separators are essential tools in mechanical and automotive repair for removing bearings, gears, and pulleys. Pullers are commonly used for extracting components from shafts without causing damage, ideal for automotive, industrial machinery, and bicycle maintenance. Separators specialize in safely wedging between tightly fitted parts, making them suitable for removing bearings stuck on shafts or pressed into housings.

Pros and Cons Comparison

Pullers offer precise force application and are ideal for removing gears, bearings, and pulleys without causing damage, but they can be limited by size and accessibility constraints. Separators excel in extracting tightly fitted parts in confined spaces, providing a versatile solution where pullers may not fit, though they often require more setup time and specialized handling. Choosing between a puller and separator depends on the specific mechanical task, space availability, and the need for precise or robust extraction.

Material Compatibility

Pullers and separators are both essential tools for removing mechanical parts, but their material compatibility differs significantly. Pullers are typically made from high-strength steel alloys that ensure durability and resistance to deformation when working with ferrous and non-ferrous metal components. Separators often feature hardened steel jaws with heat-treated surfaces designed specifically to grip delicate or coated surfaces without causing damage, making them suitable for use on softer materials like aluminum or plastic composites.

Selection Guide: Puller or Separator

Choosing between a puller and a separator depends on the specific mechanical application and type of component removal required. Pullers are ideal for extracting gears, bearings, and pulleys tightly fitted on shafts, offering a controlled and precise force. Separators efficiently detach components from shafts or housings where limited space exists or direct gripping is impractical, making them suitable for axle or bearing removal in confined areas.

Maintenance and Safety Tips

Regular inspection and lubrication of pullers and separators are essential to prevent mechanical failure and ensure smooth operation. Using the correct size and type of tool for the task helps avoid damage to the components and reduces the risk of injury. Always wear appropriate personal protective equipment (PPE) such as gloves and safety glasses, and follow manufacturer guidelines for safe usage to minimize accidents during maintenance and removal procedures.

Conclusion and Recommendations

Pullers offer enhanced force control and precision, making them ideal for delicate tasks or components with tight tolerances, while separators excel in handling larger, more robust fittings with their durability and broad application range. For automotive and heavy machinery repair, pullers are recommended to minimize damage and increase efficiency, whereas separators are better suited for industrial maintenance requiring higher torque and versatility. Selecting the appropriate tool depends on the specific mechanical requirements and component fragility to optimize performance and safety.

Puller vs separator Infographic

libmatt.com

libmatt.com