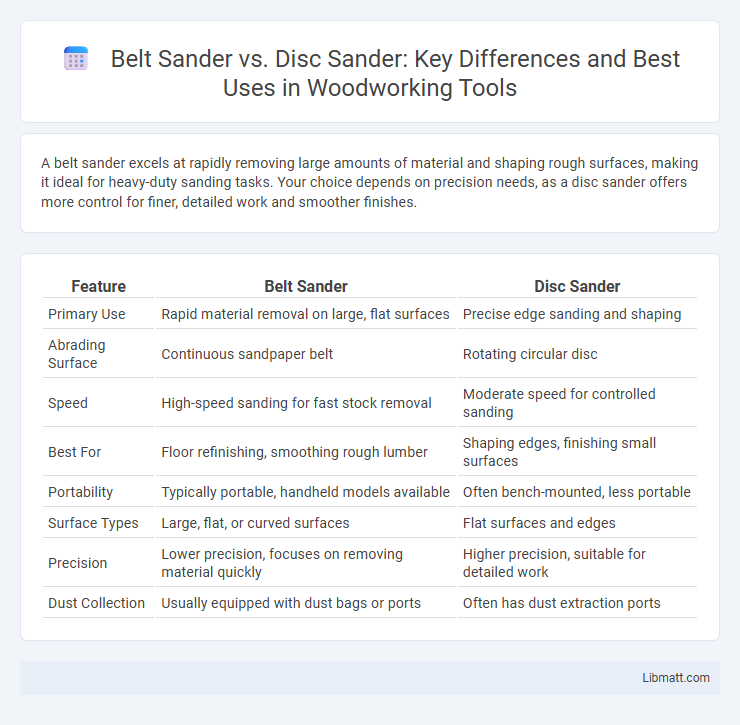

A belt sander excels at rapidly removing large amounts of material and shaping rough surfaces, making it ideal for heavy-duty sanding tasks. Your choice depends on precision needs, as a disc sander offers more control for finer, detailed work and smoother finishes.

Table of Comparison

| Feature | Belt Sander | Disc Sander |

|---|---|---|

| Primary Use | Rapid material removal on large, flat surfaces | Precise edge sanding and shaping |

| Abrading Surface | Continuous sandpaper belt | Rotating circular disc |

| Speed | High-speed sanding for fast stock removal | Moderate speed for controlled sanding |

| Best For | Floor refinishing, smoothing rough lumber | Shaping edges, finishing small surfaces |

| Portability | Typically portable, handheld models available | Often bench-mounted, less portable |

| Surface Types | Large, flat, or curved surfaces | Flat surfaces and edges |

| Precision | Lower precision, focuses on removing material quickly | Higher precision, suitable for detailed work |

| Dust Collection | Usually equipped with dust bags or ports | Often has dust extraction ports |

Introduction: Belt Sander vs Disc Sander

Belt sanders offer rapid material removal with a continuous loop of abrasive belts, ideal for leveling large wooden surfaces and shaping edges. Disc sanders utilize a rotating circular abrasive plate, providing precision sanding for curved edges and end grain smoothing. Choosing between belt and disc sanders depends on project requirements, surface type, and desired finish quality.

What is a Belt Sander?

A belt sander is a powerful sanding tool featuring a continuous loop of sandpaper that moves rapidly over two drums to smooth and shape wood, metal, or other materials. It excels in removing large amounts of material quickly, making it ideal for heavy-duty sanding tasks like flattening rough surfaces or trimming edges. Your choice of a belt sander supports efficient, consistent sanding where fast stock removal and aggressive abrasion are required.

What is a Disc Sander?

A disc sander features a circular abrasive disc mounted on a rotating plate, ideal for smoothing flat surfaces, shaping edges, and removing material quickly on smaller projects. It operates at high speeds, allowing precise control for detailed sanding tasks, especially on wood, metal, and plastic. Compared to a belt sander, it offers better accuracy for edge work and curved surfaces due to its stationary disc and adjustable table.

Key Differences Between Belt Sander and Disc Sander

Belt sanders feature a continuous loop of sandpaper ideal for rapid stock removal and large surface leveling, while disc sanders use a rotating abrasive disc suited for precision edges and fine finishing. Belt sanders excel in handling flat, broad surfaces, whereas disc sanders provide better control on curves and corners. The choice depends on project requirements, with belt sanders favoring speed and efficiency and disc sanders prioritizing accuracy and detail work.

Applications: When to Use a Belt Sander

A belt sander is ideal for rapidly removing large amounts of material, making it perfect for flattening rough surfaces, shaping edges, and sanding wide, flat areas like doors or tabletops. You should choose a belt sander when working on heavy-duty projects that require aggressive sanding, such as leveling wood or smoothing rough lumber. Its powerful abrasive belt is designed for efficiency in large-scale woodworking and metalworking tasks where speed and surface uniformity are essential.

Applications: When to Use a Disc Sander

A disc sander excels in precision tasks such as shaping edges, smoothing curves, and finishing small or intricate surfaces where control is crucial. Its rotating disc design allows for detailed work on wood, metal, or plastic, making it ideal for cabinetry, furniture making, and fine woodworking projects. You should choose a disc sander when your project demands accuracy and a fine finish on smaller areas rather than fast, aggressive material removal.

Pros and Cons of Belt Sanders

Belt sanders offer powerful and efficient material removal, making them ideal for large, flat surfaces and heavy-duty sanding tasks, while their high speed can sometimes cause uneven sanding or gouging if not handled carefully. They are generally easier to control for aggressive stock removal, but their size and noise level may be a drawback in precision work or small spaces. Your choice depends on the project's scale and desired finish, with belt sanders excelling in speed and volume but requiring skill to avoid damaging your workpiece.

Pros and Cons of Disc Sanders

Disc sanders offer precise control for shaping and finishing wood or metal surfaces, making them ideal for detailed sanding tasks. They typically provide a smooth, consistent finish but can struggle with removing large amounts of material quickly compared to belt sanders. Limited to flat surfaces, disc sanders may not be as versatile as belt sanders for sanding curves or irregular shapes.

Safety Tips for Using Belt and Disc Sanders

Always wear safety goggles and a dust mask when operating belt and disc sanders to protect against airborne debris and particles. Ensure the workpiece is securely clamped or held firmly against the sanding surface to prevent kickback and loss of control. Keep fingers and loose clothing away from the moving sanding belts or discs to avoid serious injuries and always disconnect the tool from power before changing sanding belts or discs.

Conclusion: Choosing the Right Sander for Your Project

Selecting the right sander depends on the specific requirements of your project, with belt sanders excelling in rapid material removal on flat, large surfaces and disc sanders offering precision for shaping and smoothing edges. Belt sanders are ideal for heavy-duty tasks like floor refinishing, while disc sanders provide versatility for detailed work on smaller pieces. Understanding the distinct capabilities of each tool ensures efficient sanding and superior finish quality.

Belt sander vs disc sander Infographic

libmatt.com

libmatt.com