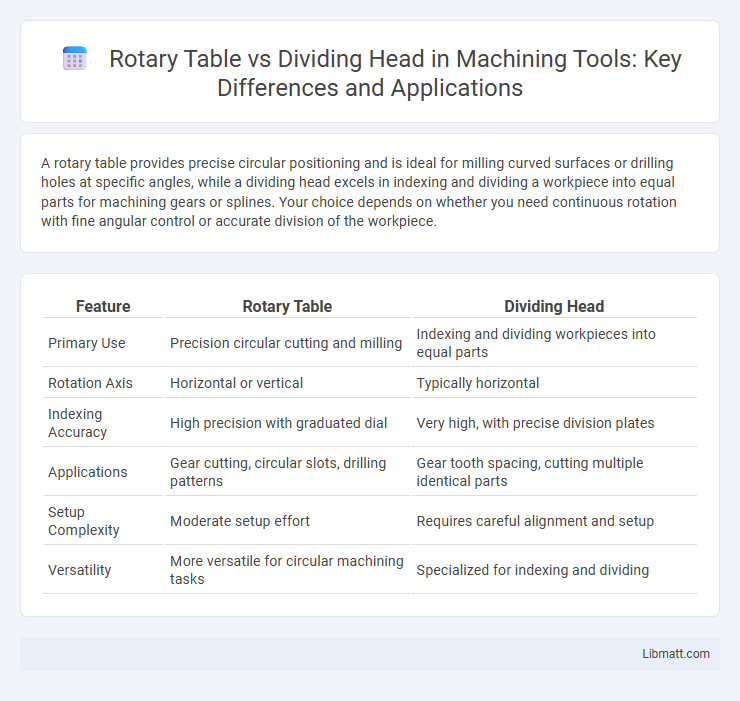

A rotary table provides precise circular positioning and is ideal for milling curved surfaces or drilling holes at specific angles, while a dividing head excels in indexing and dividing a workpiece into equal parts for machining gears or splines. Your choice depends on whether you need continuous rotation with fine angular control or accurate division of the workpiece.

Table of Comparison

| Feature | Rotary Table | Dividing Head |

|---|---|---|

| Primary Use | Precision circular cutting and milling | Indexing and dividing workpieces into equal parts |

| Rotation Axis | Horizontal or vertical | Typically horizontal |

| Indexing Accuracy | High precision with graduated dial | Very high, with precise division plates |

| Applications | Gear cutting, circular slots, drilling patterns | Gear tooth spacing, cutting multiple identical parts |

| Setup Complexity | Moderate setup effort | Requires careful alignment and setup |

| Versatility | More versatile for circular machining tasks | Specialized for indexing and dividing |

Introduction to Rotary Tables and Dividing Heads

Rotary tables and dividing heads are essential tools in machining for precise angular positioning and indexing of workpieces. Rotary tables primarily enable smooth rotation around a vertical axis, enhancing milling operations like circular cuts and gear cutting, while dividing heads provide accurate division of the workpiece into equal segments for complex machining tasks. Your choice between these tools depends on the required precision and the specific application, with rotary tables favored for versatility and dividing heads for precise angular indexing.

Key Differences Between Rotary Tables and Dividing Heads

Rotary tables provide continuous rotation for precise angular positioning, ideal for milling circular slots and complex curved surfaces, while dividing heads offer indexed rotation with fixed divisions for repetitive, accurate work like gear cutting and drilling holes at specific angles. Rotary tables excel in smooth, infinite rotations, whereas dividing heads emphasize accuracy in dividing a circle into equal parts with mechanical indexing systems or digital readouts. Your choice depends on whether you require seamless, adjustable rotation or precise, repeatable angular indexing for your machining tasks.

Construction and Design Comparison

Rotary tables feature a compact, high-precision circular platform mounted on a base, allowing smooth 360-degree rotation with fine indexing via a worm gear mechanism. Dividing heads incorporate a more complex assembly with a spindle, tailstock, and indexing plates, designed for versatile angular division and multi-axis operations on milling machines. Your choice depends on precision needs and machining complexity, as rotary tables excel in continuous rotation while dividing heads offer intricate, indexed angular positioning.

Working Principles: How Each Tool Operates

A rotary table operates by rotating a workpiece around a vertical axis, enabling precise circular cutting, drilling, or milling through manual or CNC control. A dividing head indexes the workpiece at specific angles or divisions, using a worm gear mechanism to achieve accurate angular positioning for operations like gear cutting and slotting. Both tools enhance machining precision by controlling rotational movement, but a rotary table primarily offers continuous rotation, whereas a dividing head provides discrete indexed positioning.

Accuracy and Precision: Which is Better?

Rotary tables offer higher precision with smooth, continuous rotation ideal for complex machining and indexing, achieving angular accuracy within arc-seconds. Dividing heads provide excellent repeatability for discrete angle divisions but may have slightly lower accuracy due to mechanical backlash and manual adjustments. For high-precision tasks, rotary tables are generally preferred, while dividing heads suit applications requiring indexed positioning with moderate precision.

Application Areas for Rotary Tables

Rotary tables are widely used in precision machining processes such as milling, drilling, and grinding, enabling accurate angular positioning of workpieces for complex geometries. They excel in applications requiring circular interpolation, dividing, and indexing, making them ideal for creating gears, cam profiles, and turbine blades. Your manufacturing setup benefits from enhanced flexibility and repeatability when integrating rotary tables for tasks involving multi-axis machining and precise component alignment.

Application Areas for Dividing Heads

Dividing heads are essential in machining for precise angular indexing and workpiece rotation, making them ideal for applications like gear cutting, drilling, and milling operations requiring accurate division of circles. Their ability to hold workpieces securely and index them at exact increments supports tasks such as cutting splines, slots, and complex polygonal shapes. You benefit from enhanced precision and versatility in manufacturing components with consistent angular spacing using dividing heads.

Setup and Ease of Use

Rotary tables offer straightforward setup with their integrated base and often come with digital readouts for precise angle adjustments, making them user-friendly for milling operations requiring circular cuts. Dividing heads require more complex setup, involving indexing plates and manual calculations to achieve accurate divisions, which can be time-consuming for beginners. While rotary tables excel in speed and ease for repetitive tasks, dividing heads provide greater flexibility for complex indexing in gear cutting and drilling applications.

Cost and Investment Considerations

Rotary tables generally involve lower initial costs compared to dividing heads, making them more accessible for small shops or hobbyists with limited budgets. Dividing heads, while often costlier upfront, offer greater precision and flexibility for complex machining tasks, justifying their higher investment for professional and industrial applications. Evaluating long-term productivity and project requirements is essential to determine the appropriate balance between cost and functional benefits.

Choosing the Right Tool for Your Workshop

Choosing between a rotary table and a dividing head depends on your workshop's precision needs and machining tasks. Rotary tables excel in milling circular slots and complex angular cuts with high accuracy, while dividing heads are ideal for indexing and dividing workpieces in precise increments, especially in gear cutting and drilling operations. Evaluate your project requirements, considering factors like setup flexibility and desired angular resolution, to select the tool that maximizes efficiency and machining precision.

Rotary table vs dividing head Infographic

libmatt.com

libmatt.com