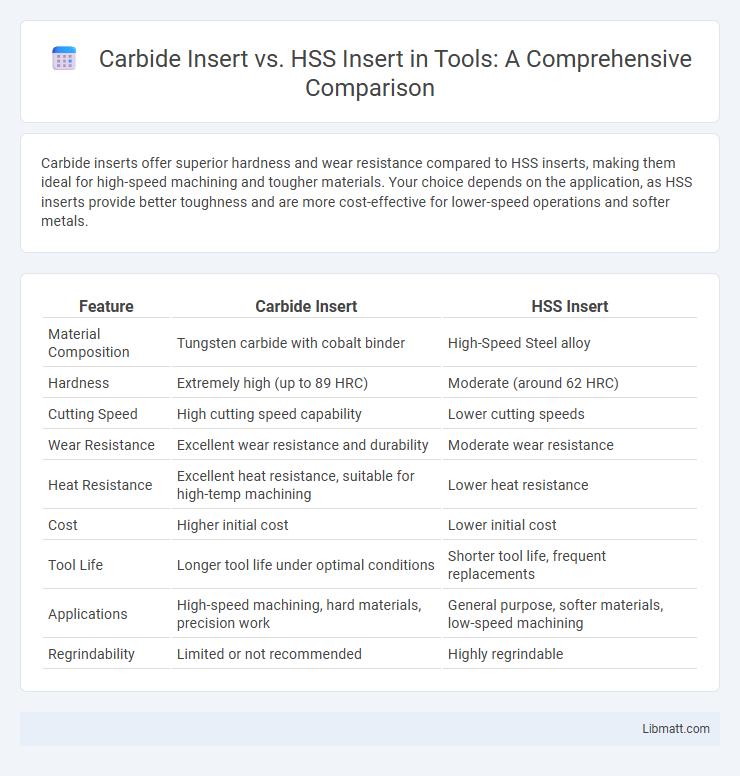

Carbide inserts offer superior hardness and wear resistance compared to HSS inserts, making them ideal for high-speed machining and tougher materials. Your choice depends on the application, as HSS inserts provide better toughness and are more cost-effective for lower-speed operations and softer metals.

Table of Comparison

| Feature | Carbide Insert | HSS Insert |

|---|---|---|

| Material Composition | Tungsten carbide with cobalt binder | High-Speed Steel alloy |

| Hardness | Extremely high (up to 89 HRC) | Moderate (around 62 HRC) |

| Cutting Speed | High cutting speed capability | Lower cutting speeds |

| Wear Resistance | Excellent wear resistance and durability | Moderate wear resistance |

| Heat Resistance | Excellent heat resistance, suitable for high-temp machining | Lower heat resistance |

| Cost | Higher initial cost | Lower initial cost |

| Tool Life | Longer tool life under optimal conditions | Shorter tool life, frequent replacements |

| Applications | High-speed machining, hard materials, precision work | General purpose, softer materials, low-speed machining |

| Regrindability | Limited or not recommended | Highly regrindable |

Introduction to Cutting Inserts

Cutting inserts, essential in machining processes, come primarily in two types: carbide and high-speed steel (HSS). Carbide inserts provide superior hardness and wear resistance, making them ideal for high-speed cutting and tough materials, while HSS inserts offer greater toughness and are more suitable for lower-speed operations and intricate finishes. Understanding the differences helps you choose the right insert for maximizing tool life and machining efficiency.

What are Carbide Inserts?

Carbide inserts are cutting tools made from a composite material composed mainly of tungsten carbide particles bonded with a metallic binder, offering exceptional hardness and wear resistance. These inserts are widely used in machining operations such as turning, milling, and drilling to enhance tool life and machining precision compared to High-Speed Steel (HSS) inserts. You benefit from improved productivity and durability when choosing carbide inserts for high-speed and heavy-duty applications.

What are HSS Inserts?

HSS inserts, or High-Speed Steel inserts, are cutting tools made from a high-alloy steel known for its toughness and resistance to high temperatures during machining. They offer excellent edge retention and are ideal for applications requiring moderate cutting speeds and interrupted cuts. HSS inserts are commonly used in metalworking industries for cutting softer materials such as aluminum and mild steel.

Performance Comparison: Carbide vs HSS

Carbide inserts deliver superior cutting performance with higher hardness and wear resistance compared to HSS inserts, enabling faster machining speeds and longer tool life. HSS inserts offer excellent toughness and are more cost-effective for lower-speed applications but wear out quicker under heavy-duty conditions. Your choice depends on the balance between cutting efficiency, tool durability, and operational cost for specific machining tasks.

Durability and Wear Resistance

Carbide inserts offer superior durability and wear resistance compared to HSS inserts, making them ideal for high-speed machining and heavy-duty applications. Their tungsten carbide composition enables them to maintain sharp edges longer and withstand higher cutting temperatures without deformation. Choosing carbide inserts enhances your machining efficiency by reducing tool changes and improving productivity.

Cutting Speed and Feed Rate Analysis

Carbide inserts typically support cutting speeds ranging from 150 to 300 meters per minute, significantly outperforming High-Speed Steel (HSS) inserts, which operate effectively between 30 to 60 meters per minute. Feed rates for carbide inserts can be increased due to their superior hardness and thermal resistance, allowing for faster material removal and improved productivity. HSS inserts, while offering better toughness for interrupted cuts, require lower feed rates to prevent rapid wear and maintain tool life.

Cost Effectiveness and Tool Life

Carbide inserts offer superior tool life compared to HSS inserts due to their enhanced hardness and wear resistance, making them more cost-effective for high-volume or precision machining tasks. While HSS inserts have a lower upfront cost, they wear out faster, leading to more frequent replacements and potentially higher long-term expenses. Your choice depends on balancing initial investment with the operational efficiency and durability required for your specific machining applications.

Surface Finish Quality Comparison

Carbide inserts provide superior surface finish quality compared to HSS inserts due to their higher hardness and wear resistance, enabling precise cutting with minimal tool deflection. The enhanced edge retention of carbide inserts results in smoother machining operations and reduced surface roughness, making them ideal for high-precision applications. In contrast, HSS inserts tend to produce rougher finishes over extended use as they dull faster and generate more heat during cutting.

Applications: Best Uses for Each Insert

Carbide inserts excel in high-speed machining and tough material applications such as stainless steel, cast iron, and hardened alloys due to their superior hardness and heat resistance. HSS inserts are ideal for low-speed operations and softer materials like mild steel and aluminum, offering better toughness and resistance to chipping in interrupted cuts. Choosing the right insert for your application ensures optimal tool life and machining efficiency, with carbide inserts favored for durability and HSS inserts for versatility in less demanding conditions.

Choosing the Right Insert for Your Needs

Carbide inserts offer superior hardness, heat resistance, and wear life, making them ideal for high-speed machining and tougher materials like stainless steel and cast iron. HSS inserts provide excellent toughness and edge strength, suitable for lower-speed operations and materials such as aluminum or mild steel. Selecting the right insert depends on your machining speed, material type, and desired tool longevity to optimize performance and cost-efficiency.

Carbide insert vs HSS insert Infographic

libmatt.com

libmatt.com