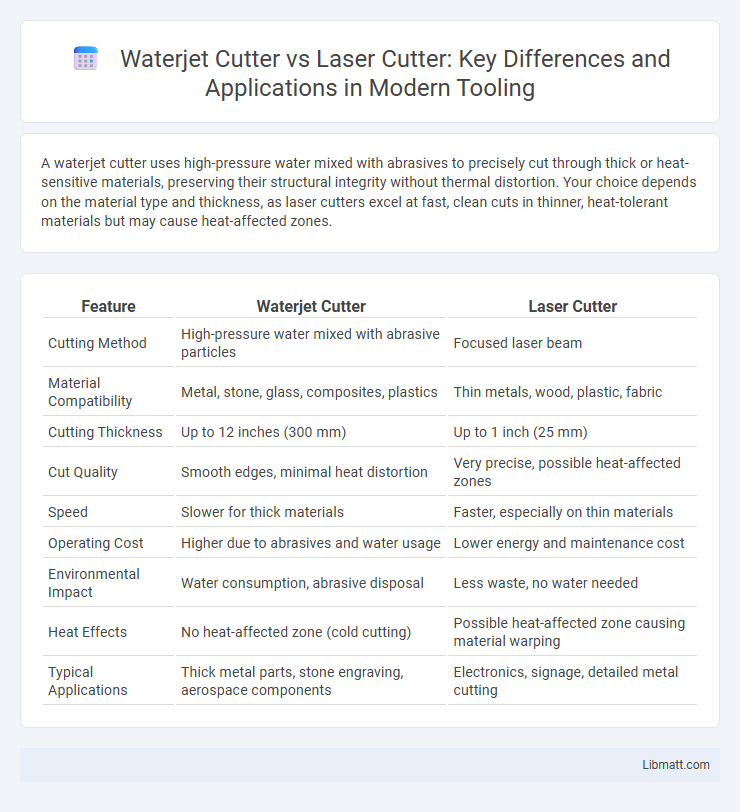

A waterjet cutter uses high-pressure water mixed with abrasives to precisely cut through thick or heat-sensitive materials, preserving their structural integrity without thermal distortion. Your choice depends on the material type and thickness, as laser cutters excel at fast, clean cuts in thinner, heat-tolerant materials but may cause heat-affected zones.

Table of Comparison

| Feature | Waterjet Cutter | Laser Cutter |

|---|---|---|

| Cutting Method | High-pressure water mixed with abrasive particles | Focused laser beam |

| Material Compatibility | Metal, stone, glass, composites, plastics | Thin metals, wood, plastic, fabric |

| Cutting Thickness | Up to 12 inches (300 mm) | Up to 1 inch (25 mm) |

| Cut Quality | Smooth edges, minimal heat distortion | Very precise, possible heat-affected zones |

| Speed | Slower for thick materials | Faster, especially on thin materials |

| Operating Cost | Higher due to abrasives and water usage | Lower energy and maintenance cost |

| Environmental Impact | Water consumption, abrasive disposal | Less waste, no water needed |

| Heat Effects | No heat-affected zone (cold cutting) | Possible heat-affected zone causing material warping |

| Typical Applications | Thick metal parts, stone engraving, aerospace components | Electronics, signage, detailed metal cutting |

Introduction to Waterjet and Laser Cutters

Waterjet cutters use a high-pressure stream of water mixed with abrasive materials to precisely cut a wide range of metals, stone, and composites without generating heat. Laser cutters employ focused laser beams to melt or vaporize material, offering high precision for metals, plastics, and wood with minimal mechanical stress. Both technologies excel in different applications depending on material thickness, required precision, and thermal sensitivity.

How Waterjet Cutters Work

Waterjet cutters operate by propelling a high-pressure stream of water mixed with abrasive particles to cut through materials with precision and minimal heat impact. The waterjet stream, reaching pressures up to 60,000 psi, erodes material cleanly without causing thermal distortion or melting. This method excels in cutting thick, heat-sensitive materials such as metals, stone, and composites, providing smooth edges and maintaining structural integrity.

How Laser Cutters Work

Laser cutters operate by focusing a high-powered laser beam onto a small area of the material, causing it to heat, melt, or vaporize precisely along the cutting path. The concentrated energy of the laser creates narrow, clean cuts with minimal thermal distortion, ideal for metals, plastics, and wood. Advanced control systems guide the laser beam with high precision, enabling intricate designs and consistent quality in manufacturing.

Materials Supported by Waterjet vs Laser Cutting

Waterjet cutters can precisely cut a wide range of materials including metals, stone, glass, ceramics, and composites without altering the material's intrinsic properties due to heat. Laser cutters excel in cutting metals, plastics, wood, and acrylics but may cause heat-affected zones leading to edge distortion or material warping. The choice between waterjet and laser cutting depends largely on the material composition and the need to avoid thermal damage during the cutting process.

Cutting Speed and Precision Comparison

Waterjet cutters achieve cutting speeds of up to 60 inches per minute on softer materials, offering superior precision with tolerances as tight as +-0.001 inches, ideal for intricate patterns in thick metals. Laser cutters excel in speed on thin materials, reaching cutting rates over 200 inches per minute with precision commonly around +-0.002 inches, delivering clean edges on plastics, wood, and sheet metal. The choice hinges on material thickness and required detail, with waterjet preferred for heavy-duty, precise cuts and laser cutters favored for rapid processing of thin substrates.

Thickness Limitations of Waterjet and Laser Cutters

Waterjet cutters excel in slicing through thick materials, handling up to 8 inches of steel or stone with ease, whereas laser cutters typically max out around 1 inch for metals due to heat-affected zones. Your choice depends on the material thickness and precision required; waterjets offer cold cutting that avoids thermal distortion, making them ideal for thick or heat-sensitive materials. Laser cutters provide faster and more precise cuts on thinner materials, but their effectiveness diminishes as thickness increases.

Edge Quality and Finish Differences

Waterjet cutters produce smooth, clean edges with minimal heat-affected zones, preserving material integrity and preventing warping. Laser cutters deliver highly precise edges but may cause slight discoloration or melting on heat-sensitive materials due to the intense heat generated. Your choice depends on whether edge quality demands cold-cut precision or if fine, detailed finishes from laser cutting suit your project better.

Safety Considerations for Both Technologies

Waterjet cutters operate using high-pressure water mixed with abrasive materials, posing risks such as skin lacerations and high noise levels, necessitating protective gear like gloves and ear protection. Laser cutters emit intense beams that can cause severe eye damage and skin burns; therefore, wearing specialized safety goggles and ensuring proper ventilation to avoid inhalation of harmful fumes is critical. Your safe operation of either technology depends on adherence to manufacturer guidelines, use of appropriate personal protective equipment, and maintaining well-ventilated workspaces.

Cost and Maintenance of Waterjet vs Laser Cutters

Waterjet cutters typically involve higher operational costs due to the need for abrasive materials and frequent wear on parts like nozzles and pumps, whereas laser cutters have lower consumable expenses but require costly initial investment and periodic maintenance of laser tubes and optics. Maintenance for waterjets includes regular replacement of high-pressure seals and abrasive residue cleanup, while laser cutters demand careful upkeep of mirrors, lenses, and cooling systems to maintain cutting precision. Your choice between waterjet and laser cutting should consider these ongoing expenses alongside the specific material requirements and production volume.

Choosing the Right Cutter for Your Application

Waterjet cutters excel in cutting thick, heat-sensitive, or composite materials without generating heat-affected zones, making them ideal for applications requiring precise, cold cutting of metals, stone, or glass. Laser cutters provide high-speed, high-precision cuts on thinner materials such as plastics, wood, and metals, with fine detail and smooth edges but may cause thermal distortion on heat-sensitive items. Your choice depends on material type, thickness, finish requirements, and budget constraints to achieve optimal cutting performance and quality.

Waterjet cutter vs laser cutter Infographic

libmatt.com

libmatt.com