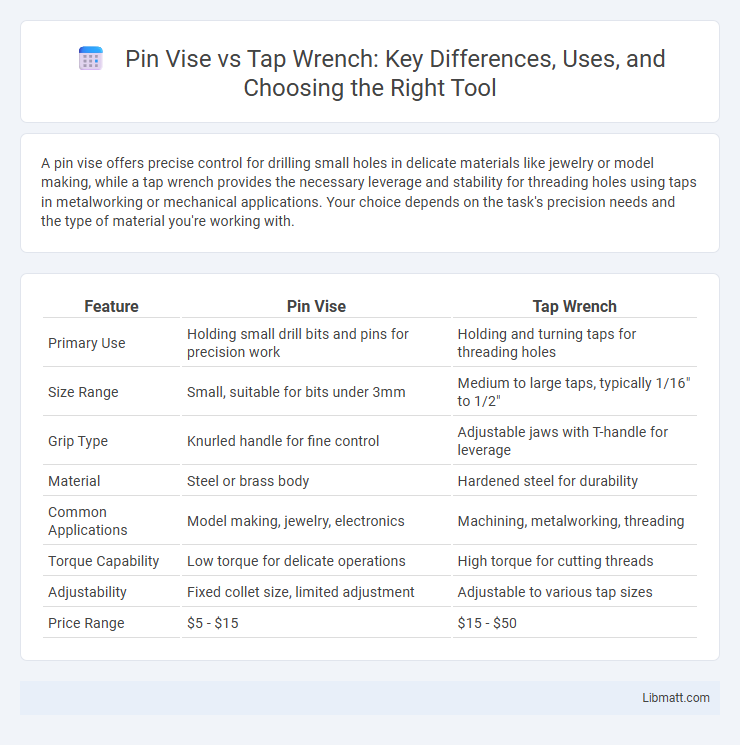

A pin vise offers precise control for drilling small holes in delicate materials like jewelry or model making, while a tap wrench provides the necessary leverage and stability for threading holes using taps in metalworking or mechanical applications. Your choice depends on the task's precision needs and the type of material you're working with.

Table of Comparison

| Feature | Pin Vise | Tap Wrench |

|---|---|---|

| Primary Use | Holding small drill bits and pins for precision work | Holding and turning taps for threading holes |

| Size Range | Small, suitable for bits under 3mm | Medium to large taps, typically 1/16" to 1/2" |

| Grip Type | Knurled handle for fine control | Adjustable jaws with T-handle for leverage |

| Material | Steel or brass body | Hardened steel for durability |

| Common Applications | Model making, jewelry, electronics | Machining, metalworking, threading |

| Torque Capability | Low torque for delicate operations | High torque for cutting threads |

| Adjustability | Fixed collet size, limited adjustment | Adjustable to various tap sizes |

| Price Range | $5 - $15 | $15 - $50 |

Introduction to Pin Vise and Tap Wrench

Pin vises are small, hand-held tools designed for precision drilling of tiny holes in materials like wood, plastic, or metal, commonly used in model making and jewelry. Tap wrenches, on the other hand, are specialized tools meant to hold and turn taps for threading internal screw threads in metalworking or machining tasks. Your choice between these tools depends on whether you require fine drilling accuracy or reliable threading capability.

What is a Pin Vise?

A pin vise is a small, handheld tool designed to hold tiny drill bits or wire for precise manual drilling or twisting tasks, commonly used in jewelry making, model building, and electronics. It features a chuck that tightens to grip the tool securely, allowing for controlled rotations and delicate manipulation. Your ability to work with fine details is enhanced by the pin vise's compact and ergonomic design, making it ideal for intricate projects where a tap wrench might be too bulky.

What is a Tap Wrench?

A tap wrench is a hand tool specifically designed to hold and turn taps for cutting internal threads in materials like metal or plastic. It features adjustable jaws to securely grip various sizes of taps, providing precise control and leverage during threading operations. Commonly used in machining and metalworking, tap wrenches enable accurate and efficient tapping, essential for creating threaded holes.

Key Differences Between Pin Vise and Tap Wrench

Pin vise and tap wrench serve distinct purposes in precision work; a pin vise is primarily designed for holding small drill bits or wires, offering fine control for delicate tasks such as jewelry making or model crafting. In contrast, a tap wrench is specifically engineered to grip and turn taps for threading holes, with a robust handle providing the necessary torque for cutting threads in metal or plastic. The key differences lie in their size, grip mechanism, and application, where pin vises prioritize precision and light-duty handling while tap wrenches focus on strength and durability for threading operations.

Common Uses for Pin Vises

Pin vises are commonly used for precision drilling, especially in jewelry making, model building, and electronics where small, delicate holes are required. Their ergonomic design allows for controlled, detailed work on materials like wood, plastic, and soft metals. Unlike tap wrenches, pin vises excel in handling tiny drill bits and wire wrapping tasks that demand fine manual dexterity.

Typical Applications of Tap Wrenches

Tap wrenches are primarily used in metalworking and mechanical tasks for threading holes with precision, making them essential tools in automotive repair, machinery maintenance, and manufacturing. They provide the leverage needed to turn taps and create internal screw threads in materials like steel, aluminum, and brass. Unlike pin vises, which are ideal for holding small drill bits and wire, tap wrenches offer controlled torque for accurate threading in medium to large-scale applications.

Advantages and Disadvantages: Pin Vise

A pin vise offers precise control and is ideal for delicate tasks such as jewelry making or model building, allowing for accurate hand drilling of small holes. However, it lacks the torque and leverage of a tap wrench, making it less effective for threading tough materials or larger taps. While lightweight and compact, the pin vise's manual operation can be time-consuming and less efficient for heavy-duty tapping.

Pros and Cons: Tap Wrench

A tap wrench offers superior leverage and control for threading tasks, making it ideal for precise and consistent screw thread cutting in metalworking or woodworking. However, its larger size and complexity can limit maneuverability in tight spaces compared to a compact pin vise. Your choice should consider whether precise tap control or access to confined areas is more critical for your project.

How to Choose Between Pin Vise and Tap Wrench

Choosing between a pin vise and a tap wrench depends on the precision and scale of the task; a pin vise is ideal for drilling tiny holes or holding small drill bits and wires with fine control, commonly used in jewelry making or model crafting. A tap wrench is suited for threading tasks requiring uniform torque and strength, such as cutting internal threads in metal or hard materials, offering better leverage for taps ranging from small to large sizes. Consider the size of your workpiece, the required torque, and the intricacy of the task to select the appropriate tool for optimal performance and accuracy.

Conclusion: Pin Vise vs Tap Wrench

Pin vise excels in precision tasks such as holding small drill bits or wire for delicate work, offering superior control and maneuverability. Tap wrenches provide strong leverage and torque essential for threading and tapping operations in metalworking, ensuring consistent and accurate thread creation. Selecting between a pin vise and tap wrench depends on the specific application, with pin vises ideal for light, detailed tasks and tap wrenches suited for robust threading activities.

Pin vise vs tap wrench Infographic

libmatt.com

libmatt.com