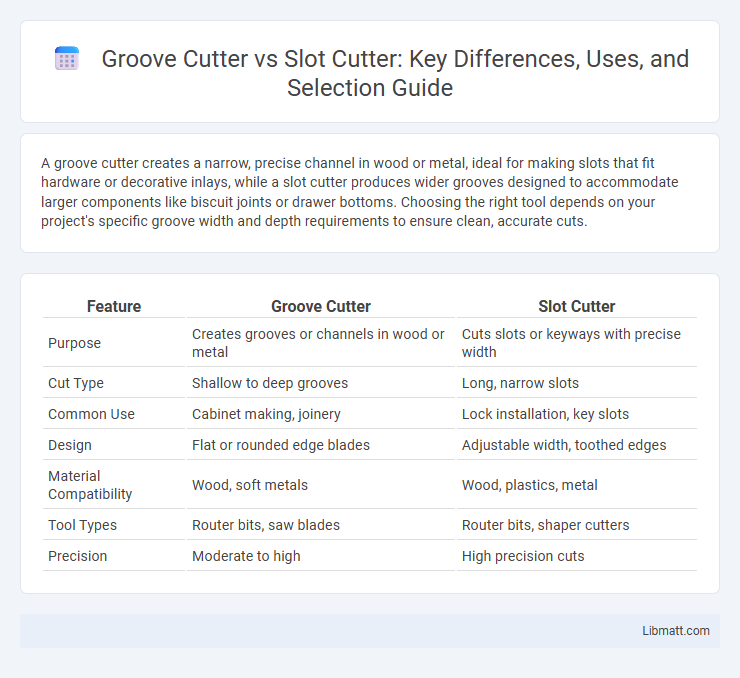

A groove cutter creates a narrow, precise channel in wood or metal, ideal for making slots that fit hardware or decorative inlays, while a slot cutter produces wider grooves designed to accommodate larger components like biscuit joints or drawer bottoms. Choosing the right tool depends on your project's specific groove width and depth requirements to ensure clean, accurate cuts.

Table of Comparison

| Feature | Groove Cutter | Slot Cutter |

|---|---|---|

| Purpose | Creates grooves or channels in wood or metal | Cuts slots or keyways with precise width |

| Cut Type | Shallow to deep grooves | Long, narrow slots |

| Common Use | Cabinet making, joinery | Lock installation, key slots |

| Design | Flat or rounded edge blades | Adjustable width, toothed edges |

| Material Compatibility | Wood, soft metals | Wood, plastics, metal |

| Tool Types | Router bits, saw blades | Router bits, shaper cutters |

| Precision | Moderate to high | High precision cuts |

Introduction to Groove Cutters and Slot Cutters

Groove cutters and slot cutters are essential woodworking tools designed for creating precise channels and grooves in wood surfaces. Groove cutters typically feature a single straight blade ideal for cutting slots with flat bottoms, while slot cutters consist of two parallel blades that can cut wider, adjustable grooves in one pass. Both tools are compatible with routers or shapers and are selected based on the specific cut profile and material thickness required for joinery or decorative applications.

Core Differences: Groove Cutter vs Slot Cutter

Groove cutters create deep, narrow channels primarily for decorative or functional grooves, while slot cutters produce wide, flat-bottomed grooves ideal for joinery and fitting applications. Groove cutters often have a single or double flute design for precision, whereas slot cutters feature multiple blades to efficiently remove material and create uniform slots. Your choice between the two depends on whether you need fine detail work (groove cutter) or broader, structural cuts (slot cutter).

Common Applications of Groove Cutters

Groove cutters are primarily used for creating precise, deep grooves in woodworking projects, such as dadoes, rabbets, and slots for joinery in cabinetry and furniture making. These cutters excel in applications where a clean, uniform groove is required to accommodate panels, shelves, or other structural elements. Their design allows for efficient material removal, making them ideal for tasks that demand tight tolerance and smooth finishes in hardwood and softwood alike.

Typical Uses for Slot Cutters

Slot cutters are primarily used in woodworking to create precise grooves, dadoes, and slots for joints, drawer bottoms, and panels. They enable seamless fitting of components in cabinetry, door frames, and shelving, ensuring structural integrity and aesthetic appeal. Ideal for joinery tasks requiring consistent slot width, slot cutters optimize assembly and enhance overall project durability.

Design Features: Groove Cutter Explained

Groove cutters feature a cylindrical design with multiple cutting edges arranged around the circumference, allowing them to create precise grooves or channels in wood or other materials. Their adjustable depth and width settings enable fine control over the cut dimensions, making them ideal for joinery and decorative inlays. Unlike slot cutters, groove cutters typically produce cleaner, more uniform grooves with minimal tear-out, enhancing both functionality and aesthetics.

Slot Cutter Construction and Functionality

Slot cutters feature a robust two-piece construction with precision-milled steel blades designed to create clean, uniform grooves or slots in wood. Their adjustable cutting depth and diameter enhance versatility, allowing you to achieve consistent results for joinery, dadoes, or decorative inlays. Optimized for router or spindle molder use, slot cutters maximize cutting efficiency and durability in woodworking projects.

Precision and Efficiency: Which Tool Performs Better?

Groove cutters deliver precise, consistent cuts ideal for creating clean, narrow channels in hardwood or softwood, making them highly efficient for detailed joinery work. Slot cutters excel in versatility, efficiently producing wider slots and dados but may sacrifice some precision in fine woodworking due to blade thickness and depth adjustments. For tasks requiring maximum accuracy and refined finishes, groove cutters outperform slot cutters, while slot cutters provide better efficiency on broader, less detailed cuts.

Material Compatibility: Groove and Slot Cutters

Groove cutters are designed primarily for cutting grooves in hardwood, softwood, plywood, and MDF, offering precision in creating recessed channels or decorative inlays. Slot cutters excel at making wider slots and dados in similar materials, including hardwood, softwood, plywood, and composite boards, providing versatility for joinery and fittings. Both cutters are compatible with materials like MDF and plywood, but slot cutters typically handle thicker cuts and deeper slots better than groove cutters.

Selecting the Right Cutter for Your Project

Choosing between a groove cutter and a slot cutter depends on the specific woodworking task and desired outcome. Groove cutters create precise, flat-bottomed channels ideal for joinery or decorative inlays, while slot cutters are designed to produce narrow, rounded slots perfect for fitting hardware or sliding components. Evaluating material type, slot width requirements, and cutter compatibility with your router or shaper ensures optimal performance and clean results in your project.

Cost Comparison and Value Analysis

Groove cutters typically cost more upfront than slot cutters due to their specialized design for creating precise grooves and dadoes in woodworking projects. Slot cutters offer greater value for general-purpose use, providing versatility and affordability for basic grooves and slots, making them ideal for hobbyists and small workshops. Your choice should consider the balance between initial investment and specific project requirements to maximize cost efficiency and long-term value.

Groove cutter vs slot cutter Infographic

libmatt.com

libmatt.com