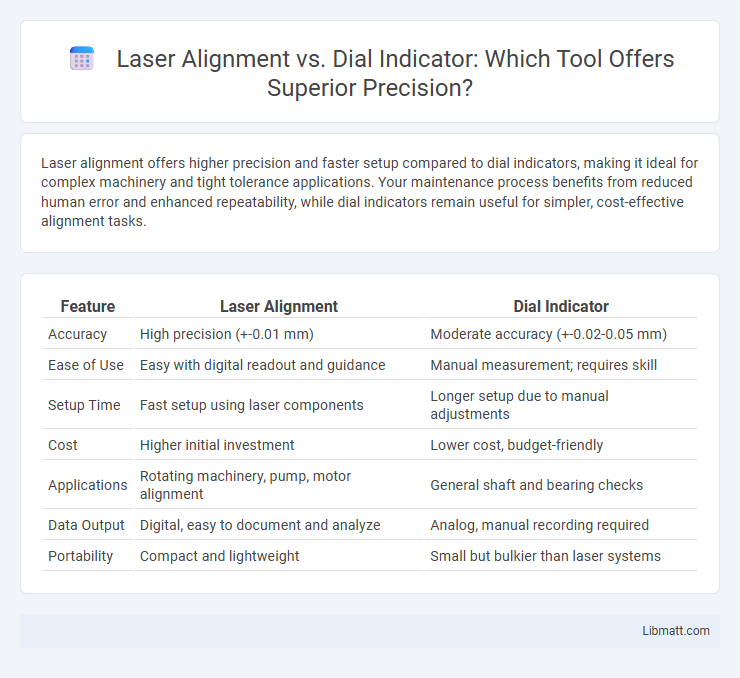

Laser alignment offers higher precision and faster setup compared to dial indicators, making it ideal for complex machinery and tight tolerance applications. Your maintenance process benefits from reduced human error and enhanced repeatability, while dial indicators remain useful for simpler, cost-effective alignment tasks.

Table of Comparison

| Feature | Laser Alignment | Dial Indicator |

|---|---|---|

| Accuracy | High precision (+-0.01 mm) | Moderate accuracy (+-0.02-0.05 mm) |

| Ease of Use | Easy with digital readout and guidance | Manual measurement; requires skill |

| Setup Time | Fast setup using laser components | Longer setup due to manual adjustments |

| Cost | Higher initial investment | Lower cost, budget-friendly |

| Applications | Rotating machinery, pump, motor alignment | General shaft and bearing checks |

| Data Output | Digital, easy to document and analyze | Analog, manual recording required |

| Portability | Compact and lightweight | Small but bulkier than laser systems |

Introduction to Shaft Alignment Techniques

Laser alignment offers high precision and efficiency by using laser beams and sensors to detect shaft misalignment, minimizing human error and reducing downtime. Dial indicators rely on mechanical measurements and manual readings, which can be less accurate and more time-consuming for shaft alignment tasks. Modern industries prefer laser alignment due to its speed, accuracy, and ability to provide detailed real-time data for optimal shaft positioning.

Overview of Laser Alignment Systems

Laser alignment systems provide precise measurement of shaft alignment using laser beams and sensors, offering higher accuracy and faster setup compared to traditional dial indicators. Unlike dial indicators that rely on manual readings and mechanical contact, laser alignment utilizes advanced optics and digital technology to eliminate human error and enable real-time data analysis. Your machinery maintenance can benefit from laser systems by reducing downtime and improving alignment repeatability in complex industrial applications.

Understanding Dial Indicator Methods

Dial indicator methods use a mechanical probe to measure shaft misalignment by detecting minute deviations through needle movement, providing accurate readings for angular and parallel misalignment. These methods are valued for simplicity, cost-effectiveness, and ease of use, especially in tight spaces or routine maintenance checks. You can achieve reliable alignment tracking with dial indicators, although they may require manual interpretation and repeated adjustments compared to laser alignment systems.

Accuracy Comparison: Laser vs Dial Indicator

Laser alignment systems offer significantly higher accuracy compared to dial indicators, with precision levels often reaching within 0.01 mm, while dial indicators typically provide accuracy around 0.01 to 0.02 mm. Laser technology minimizes human error and allows for real-time adjustments, ensuring more consistent and repeatable measurements in shaft alignment tasks. Dial indicators, although reliable, require manual reading and interpretation, which increases the risk of misalignment and lower overall accuracy.

Efficiency and Speed of Alignment

Laser alignment offers significantly higher efficiency and speed compared to dial indicators by providing precise, real-time measurements that reduce setup and adjustment times. Your alignment process benefits from automated data collection and instant visual feedback, minimizing human error and enabling quicker decision-making. Dial indicators require manual readings and multiple adjustments, making the process more time-consuming and less efficient.

User Experience and Learning Curve

Laser alignment offers a user-friendly experience with intuitive interfaces and real-time digital feedback, significantly reducing the learning curve compared to dial indicators, which require manual readings and adjustments that demand higher skill and experience. Your ability to quickly achieve precise alignments improves with laser technology due to automated measurements and error detection that minimize human error. While dial indicators remain accurate, mastering their use involves time-consuming training and interpretation, making laser alignment the preferred choice for efficient and accessible precision maintenance.

Cost Analysis: Initial Investment and ROI

Laser alignment systems typically require a higher initial investment, ranging from $5,000 to $20,000, compared to dial indicators which cost between $200 and $500. The faster setup time and higher accuracy of laser alignment lead to reduced machine downtime and maintenance costs, yielding a return on investment (ROI) within months for high-use industrial applications. Dial indicators, while affordable upfront, often incur hidden costs due to longer alignment times and lower precision, impacting overall operational efficiency.

Common Applications in Industry

Laser alignment is widely used in industries such as manufacturing, power generation, and automotive for precise shaft and machinery alignment, ensuring minimal downtime and increased equipment lifespan. Dial indicators remain common in maintenance and machine setup for measuring runout, parallelism, and flatness due to their affordability and ease of use. Your choice depends on accuracy requirements and operational efficiency, with laser alignment offering superior precision for critical applications.

Maintenance and Calibration Requirements

Laser alignment systems require less frequent maintenance and calibration compared to dial indicators, saving time and reducing downtime in industrial settings. Dial indicators need regular manual calibration to ensure accuracy, which can be labor-intensive and prone to human error. Your maintenance schedule benefits from the precision and consistency of laser technology, minimizing the risk of misalignment and costly equipment failures.

Choosing the Right Tool for Your Needs

Laser alignment offers unparalleled precision and speed, making it ideal for complex machinery requiring exact alignment, while dial indicators provide a cost-effective and reliable solution for simpler or budget-conscious tasks. Your choice depends on the accuracy demands, machine complexity, and available resources, ensuring optimal performance and reduced downtime. Evaluating these factors helps determine whether the advanced technology of laser alignment or the traditional approach of dial indicators best fits your maintenance strategy.

Laser alignment vs dial indicator Infographic

libmatt.com

libmatt.com