Mechanical hammers rely on motor-driven mechanisms to deliver consistent, controlled force, making them ideal for precise demolition or construction tasks, while pneumatic hammers use compressed air to generate powerful, rapid impacts suited for heavy-duty breaking and chiseling. Your choice depends on the need for portability, power, and maintenance preferences, with mechanical hammers typically offering quieter operation and pneumatic versions excelling in heavy industrial applications.

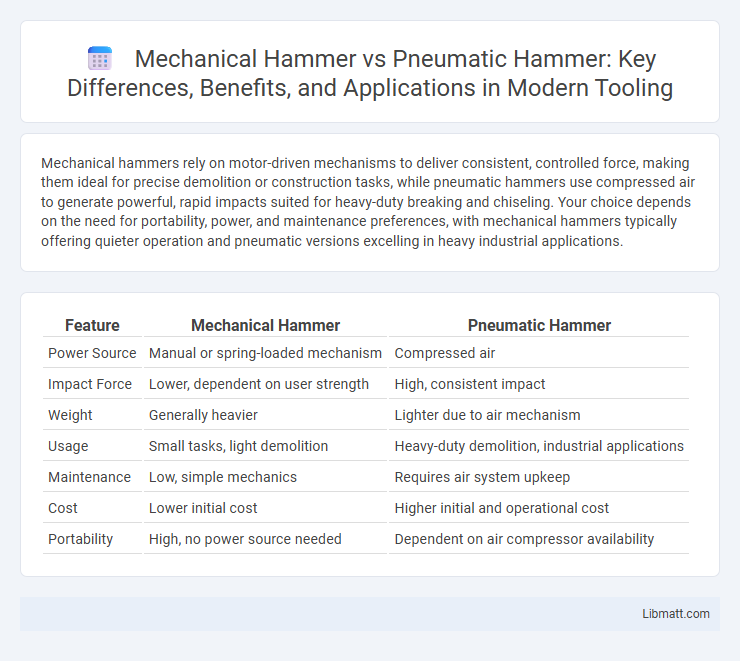

Table of Comparison

| Feature | Mechanical Hammer | Pneumatic Hammer |

|---|---|---|

| Power Source | Manual or spring-loaded mechanism | Compressed air |

| Impact Force | Lower, dependent on user strength | High, consistent impact |

| Weight | Generally heavier | Lighter due to air mechanism |

| Usage | Small tasks, light demolition | Heavy-duty demolition, industrial applications |

| Maintenance | Low, simple mechanics | Requires air system upkeep |

| Cost | Lower initial cost | Higher initial and operational cost |

| Portability | High, no power source needed | Dependent on air compressor availability |

Introduction to Mechanical and Pneumatic Hammers

Mechanical hammers utilize a motor-driven mechanism to generate force for driving nails or breaking materials, offering precise control and consistent impact energy. Pneumatic hammers operate using compressed air to deliver powerful, rapid blows, making them ideal for heavy-duty construction and demolition tasks. Both tools are essential in construction, with mechanical hammers favored for detail work and pneumatic hammers preferred for high-intensity applications due to their efficiency and power.

How Mechanical Hammers Work

Mechanical hammers operate by converting stored mechanical energy into a powerful, repetitive impact force through a spring-loaded or flywheel mechanism, which delivers consistent strikes to the target material. Unlike pneumatic hammers that rely on compressed air, mechanical hammers use a crank or cam to rotate and compress energy, releasing it on each cycle to drive nails, break concrete, or shape metal. This transfer of kinetic energy makes mechanical hammers effective for heavy-duty construction and demolition tasks where precise control and forceful impacts are required.

How Pneumatic Hammers Operate

Pneumatic hammers operate using compressed air to drive a piston that delivers repeated, high-impact blows to a work surface, providing efficient and powerful hammering action. This mechanism allows for consistent energy transfer with adjustable force, making pneumatic hammers ideal for heavy-duty tasks like demolition and breaking concrete. Unlike mechanical hammers that rely on mechanical linkages, pneumatic hammers offer smoother operation and reduced operator fatigue due to their air-powered system.

Key Differences Between Mechanical and Pneumatic Hammers

Mechanical hammers operate using a direct motor-driven mechanism generating repetitive impact force, while pneumatic hammers rely on compressed air to power their striking action, resulting in distinct energy delivery and efficiency. Mechanical hammers typically offer consistent torque and are better suited for continuous heavy-duty tasks, whereas pneumatic hammers excel in applications requiring rapid, high-frequency blows and easier maintenance due to fewer moving parts. The choice between mechanical and pneumatic hammers depends on factors such as power source availability, operational environment, and specific industrial requirements.

Application Areas for Mechanical Hammers

Mechanical hammers are commonly used in construction, metal forging, and demolition due to their ability to deliver powerful, controlled blows ideal for heavy-duty tasks. They excel in applications requiring precise impact force, such as shaping metal components or breaking concrete surfaces. Your choice of a mechanical hammer is beneficial for tasks demanding consistent hammering without reliance on compressed air.

Application Areas for Pneumatic Hammers

Pneumatic hammers are extensively utilized in construction, mining, and demolition industries due to their high power-to-weight ratio and precise control. They excel in breaking concrete, asphalt, and rock, making them ideal for roadwork, quarrying, and heavy-duty maintenance tasks. Their compatibility with air compressors allows for continuous operation in environments where electric power is restricted or hazardous.

Advantages of Mechanical Hammers

Mechanical hammers offer greater control and precision due to their direct impact mechanism, making them ideal for delicate demolition and shaping tasks. They require less maintenance compared to pneumatic hammers since they lack complex air systems and hoses, reducing operational downtime. Mechanical hammers also operate efficiently in environments without compressed air supply, enhancing portability and ease of use on various job sites.

Benefits of Pneumatic Hammers

Pneumatic hammers offer superior power-to-weight ratios, delivering efficient energy transfer that boosts productivity in heavy-duty construction tasks. Their lighter design reduces user fatigue, enhancing precision and control during extended use. You benefit from lower maintenance costs and increased reliability due to fewer moving parts compared to mechanical hammers.

Choosing the Right Hammer for Your Project

Choosing the right hammer for your project depends on factors like power source, impact force, and precision requirements. Mechanical hammers deliver consistent, high-impact force ideal for heavy demolition, while pneumatic hammers offer greater control and reduced fatigue for repetitive tasks. Your specific application and work environment will determine whether the durability of a mechanical hammer or the versatility of a pneumatic hammer best suits your needs.

Summary: Mechanical Hammer vs Pneumatic Hammer

Mechanical hammers rely on a motor-driven mechanism to deliver consistent and controlled force, making them ideal for precision tasks and heavy-duty applications. Pneumatic hammers use compressed air to generate rapid, high-impact blows suited for tasks requiring powerful, repetitive striking, such as breaking concrete or driving stakes. Your choice depends on the required impact force, operational environment, and maintenance preferences, with mechanical hammers offering versatility and pneumatic hammers providing superior power for demanding jobs.

Mechanical hammer vs pneumatic hammer Infographic

libmatt.com

libmatt.com