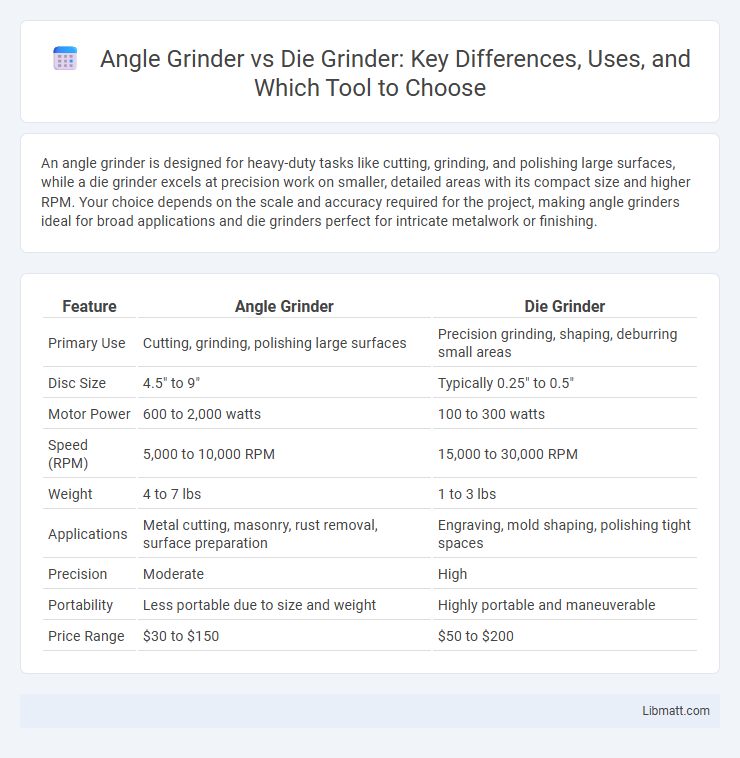

An angle grinder is designed for heavy-duty tasks like cutting, grinding, and polishing large surfaces, while a die grinder excels at precision work on smaller, detailed areas with its compact size and higher RPM. Your choice depends on the scale and accuracy required for the project, making angle grinders ideal for broad applications and die grinders perfect for intricate metalwork or finishing.

Table of Comparison

| Feature | Angle Grinder | Die Grinder |

|---|---|---|

| Primary Use | Cutting, grinding, polishing large surfaces | Precision grinding, shaping, deburring small areas |

| Disc Size | 4.5" to 9" | Typically 0.25" to 0.5" |

| Motor Power | 600 to 2,000 watts | 100 to 300 watts |

| Speed (RPM) | 5,000 to 10,000 RPM | 15,000 to 30,000 RPM |

| Weight | 4 to 7 lbs | 1 to 3 lbs |

| Applications | Metal cutting, masonry, rust removal, surface preparation | Engraving, mold shaping, polishing tight spaces |

| Precision | Moderate | High |

| Portability | Less portable due to size and weight | Highly portable and maneuverable |

| Price Range | $30 to $150 | $50 to $200 |

Introduction to Angle Grinders and Die Grinders

Angle grinders feature a rotating abrasive disc designed for heavy-duty grinding, cutting, and polishing tasks on materials like metal, stone, and concrete. Die grinders use a small, high-speed rotary tool with a rotary burr or other attachments ideal for detailed work such as shaping, deburring, and precision grinding in tight spaces. Your choice depends on the project's scale and precision requirements, with angle grinders suited for broad surface work and die grinders excelling in intricate, fine-tuning applications.

Key Differences Between Angle Grinders and Die Grinders

Angle grinders feature a larger, more powerful motor typically ranging from 4.5 to 9 inches in disc size, making them ideal for heavy-duty cutting, grinding, and polishing of metal, stone, and concrete. Die grinders are smaller, with a spindle speed of up to 35,000 RPM, designed for precision tasks like polishing, deburring, and intricate surface shaping in tight spaces. The primary difference lies in the scale and application, where angle grinders handle broad, high-impact jobs, while die grinders excel in detailed, finesse work.

Power and Performance Comparison

Angle grinders typically feature higher power ratings ranging from 500 to 2500 watts, making them ideal for heavy-duty grinding, cutting, and polishing tasks on materials like metal and concrete. Die grinders, with power usually between 200 to 700 watts, offer precision and high-speed performance suited for detailed work such as carving, deburring, and shaping. Your choice depends on the intensity and precision required, with angle grinders excelling in power and broad applications, while die grinders provide superior control for intricate projects.

Versatility and Applications

Angle grinders offer greater versatility with their ability to handle grinding, cutting, sanding, and polishing on a variety of materials, making them ideal for heavy-duty tasks and larger surfaces. Die grinders excel in precision work, reaching tight spots and intricate details in metal, wood, and plastic projects, which is crucial for fine craftsmanship and automotive applications. Choosing the right tool depends on your specific application needs, with angle grinders providing broad functionality and die grinders delivering specialized, detailed control.

Design and Ergonomics

Angle grinders feature a robust, pistol-grip design with a large, rotating disc ideal for heavy-duty grinding, cutting, and polishing tasks, providing enhanced control and power for surface work. Die grinders are typically more compact and cylindrical, designed for precision tasks and tight spaces, allowing for detailed grinding and carving with lightweight, easy-to-maneuver functionality. The ergonomic design of die grinders reduces user fatigue during extended use, while angle grinders prioritize durability and torque for demanding applications.

Types of Discs and Attachments

Angle grinders typically use larger discs ranging from 4.5 to 9 inches in diameter, including grinding wheels, cut-off wheels, flap discs, and wire brushes suitable for heavy-duty tasks like metal cutting and surface grinding. Die grinders, on the other hand, employ smaller rotary attachments such as carbide burrs, small sanding drums, grinding stones, and abrasive wheels designed for precision work and intricate detailing. The variety and size of discs and attachments determine each tool's best applications, with angle grinders excelling in coarse material removal and die grinders offering fine, controlled shaping and finishing.

Safety Considerations

Angle grinders require robust safety measures due to their high-speed disc rotation, including wearing protective gear like safety goggles, gloves, and hearing protection to prevent injuries from flying debris and sparks. Die grinders, operating at higher speeds but with smaller attachments, demand careful handling and secure attachment of bits to avoid accidents caused by bit dislodgement or tool slippage. Both tools should be used with proper guards and within recommended operational limits to minimize risks of cuts, abrasions, and eye injuries.

Cost and Maintenance

Angle grinders generally have a lower upfront cost compared to die grinders and require less frequent maintenance due to their robust design and fewer precision components. Die grinders, while typically more expensive, demand meticulous upkeep, including regular lubrication and careful inspection of collets and bearings, to maintain their high-speed performance and precision. Choosing between the two depends on balancing initial investment with ongoing maintenance needs and the specific application requirements.

Choosing the Right Grinder for Your Needs

Selecting the right grinder depends on the specific application and material you're working with; angle grinders excel at heavy-duty tasks like cutting and grinding metal or masonry, offering power and versatility with larger discs typically ranging from 4 to 9 inches. Die grinders provide precision for detailed work such as polishing, carving, and deburring with smaller attachments around 0.25 to 0.5 inches, ideal for tight spaces and intricate surfaces. Evaluating factors like speed, disc size, and the required control ensures you choose a tool that maximizes efficiency and safety for your grinding projects.

Conclusion: Which Grinder Should You Choose?

Choose an angle grinder for heavy-duty tasks such as cutting, grinding, and polishing metal or masonry due to its larger size, higher power, and versatility with various disc sizes. Opt for a die grinder when precision work on smaller surfaces, detailed grinding, or intricate shaping is required, as it offers better maneuverability and finer control. Selecting the right grinder depends on the project scale, material, and required accuracy, making angle grinders ideal for robust applications and die grinders suited for detailed craftsmanship.

Angle grinder vs die grinder Infographic

libmatt.com

libmatt.com