A three-phase welder delivers more consistent power and higher efficiency, making it ideal for heavy-duty industrial welding tasks, while a single-phase welder suits lighter, portable applications due to its compatibility with standard household electrical outlets. Your choice depends on the welding intensity and availability of electrical infrastructure, with three-phase units providing smoother operation and less voltage fluctuation.

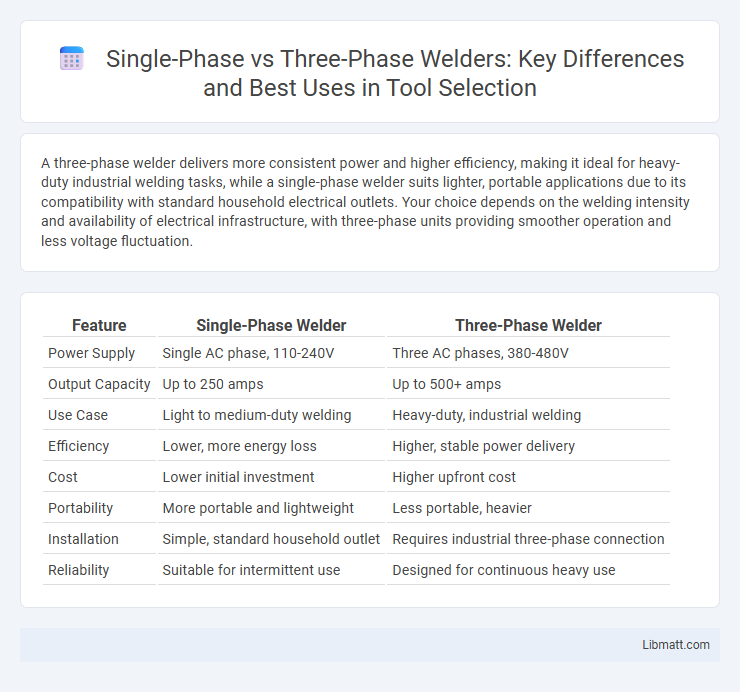

Table of Comparison

| Feature | Single-Phase Welder | Three-Phase Welder |

|---|---|---|

| Power Supply | Single AC phase, 110-240V | Three AC phases, 380-480V |

| Output Capacity | Up to 250 amps | Up to 500+ amps |

| Use Case | Light to medium-duty welding | Heavy-duty, industrial welding |

| Efficiency | Lower, more energy loss | Higher, stable power delivery |

| Cost | Lower initial investment | Higher upfront cost |

| Portability | More portable and lightweight | Less portable, heavier |

| Installation | Simple, standard household outlet | Requires industrial three-phase connection |

| Reliability | Suitable for intermittent use | Designed for continuous heavy use |

Introduction to Welding Power Sources

Single-phase welders operate on standard household electrical circuits, making them ideal for small-scale or light-duty welding tasks due to their ease of use and accessibility. Three-phase welders require a three-phase power supply, offering greater efficiency, higher power output, and more stable arcs, which suits industrial and heavy-duty welding applications. Your choice between single-phase and three-phase welding power sources depends on the power availability, project scale, and desired welding performance.

Understanding Single-Phase Welders

Single-phase welders operate on a single alternating current (AC) voltage source, typically 120V or 240V, making them ideal for home or small workshop use where power demands are lower. They are simpler in design, more portable, and easier to maintain, but generally provide less power output compared to three-phase welders, limiting their capacity for heavy-duty or industrial welding tasks. Understanding the power limitations and applications of single-phase welders helps in selecting the right equipment for light fabrication, repair, and hobbyist projects.

Overview of Three-Phase Welders

Three-phase welders utilize three alternating currents, providing consistent power delivery that enhances welding stability and efficiency for heavy-duty industrial applications. These welders support higher voltage and amperage requirements, enabling them to handle thicker metals and longer welding sessions without overheating. Their design maximizes energy utilization, resulting in smoother arc performance and reduced operating costs compared to single-phase welders.

Power Requirements and Availability

Single-phase welders operate on standard household power supply, typically 110-120 volts, making them suitable for residential use with limited power requirements. Three-phase welders require industrial power sources of 208-480 volts, providing higher power capacity and efficiency for heavy-duty welding tasks in commercial or manufacturing environments. Availability of three-phase power is more common in industrial settings, while single-phase power is widely accessible in most residential and small workshop locations.

Performance and Efficiency Comparison

Single-phase welders typically deliver lower power output and are less efficient for heavy-duty welding tasks, making them suitable for light to medium projects and portable use. Three-phase welders provide higher performance with smoother power delivery, increased efficiency, and the ability to handle more demanding industrial applications, resulting in faster welding speeds and improved weld quality. Your selection should consider the electrical infrastructure available and the intensity of your welding needs to maximize efficiency and performance.

Application Suitability and Use Cases

Single-phase welders are ideal for light to medium welding tasks and are commonly used in residential, small workshop, or hobbyist applications due to their compatibility with standard household electrical outlets. Three-phase welders provide higher power output and efficiency, making them suitable for industrial and heavy-duty welding projects requiring continuous operation and thicker materials. The choice between single-phase and three-phase welders depends on the energy infrastructure and the scale of welding work, with single-phase suited for portability and lower power needs, while three-phase supports large-scale manufacturing and fabrication environments.

Cost Differences: Initial and Operational

Single-phase welders generally have lower initial costs due to simpler design and widespread availability, making them suitable for small-scale or occasional projects. Three-phase welders, while more expensive upfront, offer greater efficiency and reduced operational costs by delivering consistent power and better performance for heavy-duty industrial use. Your choice impacts long-term expenses, as three-phase models typically consume less electricity and require less maintenance, offsetting their higher purchase price over time.

Portability and Installation Considerations

Single-phase welders excel in portability due to their compatibility with standard household outlets, allowing easy setup and use in various locations without requiring specialized electrical infrastructure. Three-phase welders, while offering higher power and efficiency, demand a three-phase power supply, making their installation more complex and typically fixed to industrial or workshop environments. Your choice should consider the balance between mobility needs and available electrical infrastructure to ensure optimal welder performance.

Maintenance and Longevity

Single-phase welders generally require less complex maintenance due to their simpler electrical design, making troubleshooting and repairs more straightforward. Three-phase welders, while potentially offering longer operational life thanks to balanced power delivery and reduced electrical stress, demand more specialized maintenance expertise to manage their intricate components. Proper upkeep of three-phase welders can significantly enhance their longevity, especially in industrial environments with heavy usage.

Choosing the Right Welder for Your Needs

Choosing the right welder for your needs depends on the power availability and project scale. Single-phase welders are ideal for home use and light-duty tasks due to their compatibility with standard household outlets and portability. Three-phase welders offer higher efficiency and power for industrial or heavy-duty applications, making them suitable for continuous, large-scale welding projects.

Single-phase welder vs three-phase welder Infographic

libmatt.com

libmatt.com