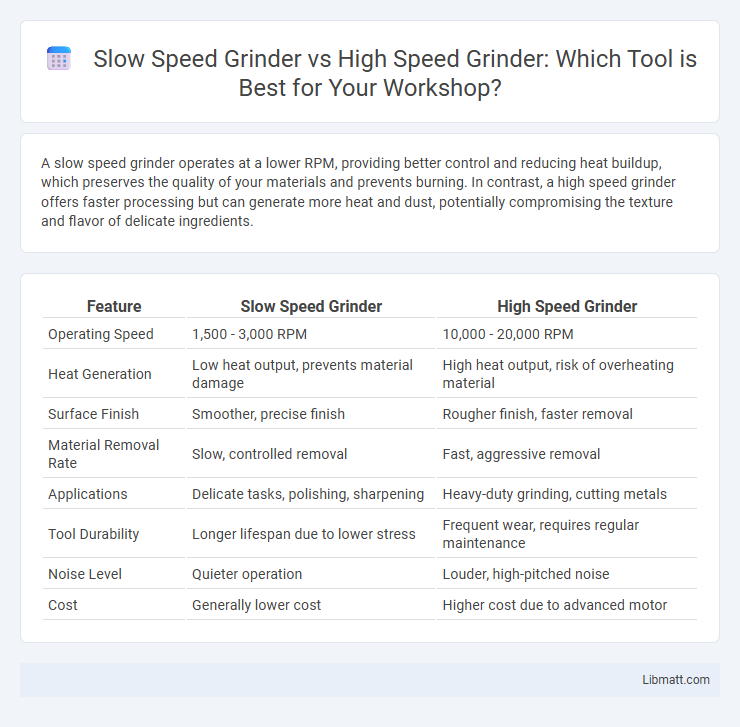

A slow speed grinder operates at a lower RPM, providing better control and reducing heat buildup, which preserves the quality of your materials and prevents burning. In contrast, a high speed grinder offers faster processing but can generate more heat and dust, potentially compromising the texture and flavor of delicate ingredients.

Table of Comparison

| Feature | Slow Speed Grinder | High Speed Grinder |

|---|---|---|

| Operating Speed | 1,500 - 3,000 RPM | 10,000 - 20,000 RPM |

| Heat Generation | Low heat output, prevents material damage | High heat output, risk of overheating material |

| Surface Finish | Smoother, precise finish | Rougher finish, faster removal |

| Material Removal Rate | Slow, controlled removal | Fast, aggressive removal |

| Applications | Delicate tasks, polishing, sharpening | Heavy-duty grinding, cutting metals |

| Tool Durability | Longer lifespan due to lower stress | Frequent wear, requires regular maintenance |

| Noise Level | Quieter operation | Louder, high-pitched noise |

| Cost | Generally lower cost | Higher cost due to advanced motor |

Introduction: Understanding Grinder Speeds

Slow speed grinders operate typically between 1,500 to 3,000 RPM, delivering enhanced control and reduced heat generation, which prevents metal discoloration and extends tool life. High speed grinders function at speeds exceeding 10,000 RPM, offering rapid material removal but increasing the risk of overheating and reduced precision. Selecting the appropriate grinder speed depends on the specific application, material type, and desired finish quality.

Key Differences Between Slow Speed and High Speed Grinders

Slow speed grinders operate at lower RPMs, generating less heat and preserving material quality, making them ideal for delicate tasks requiring precision. High speed grinders run at higher RPMs, providing faster material removal but increasing heat generation, which may affect surface finish and tool life. Your choice depends on the specific application, balancing speed with control and the type of material being processed.

Pros and Cons of Slow Speed Grinders

Slow speed grinders offer precise control and generate less heat, preserving the aroma and flavor of spices and coffee beans, which is ideal for maintaining quality in your culinary preparations. These grinders are quieter and produce fewer fines, reducing the risk of over-grinding, but they often require more time to achieve the desired consistency compared to high speed grinders. However, the slower operation may limit efficiency in high-volume settings and the equipment can be bulkier and pricier, making them better suited for small-scale or specialized use.

Pros and Cons of High Speed Grinders

High speed grinders offer rapid material removal and increased productivity, making them ideal for large-scale projects requiring efficiency. However, they generate significant heat and can cause material burnout or surface damage if not carefully managed. Their high RPM also results in increased wear on grinding components and requires more frequent maintenance compared to slow speed grinders.

Applications: Which Grinder Suits Your Needs?

Slow speed grinders excel in detailed tasks such as precision sharpening, intricate carving, and polishing where heat generation and material loss must be minimized. High speed grinders are ideal for rapid material removal, heavy-duty grinding, and cutting tasks, especially on tougher metals or thick materials requiring fast throughput. Choosing the right grinder depends on application specifics: slow speed grinders for fine, delicate work and high speed grinders for robust, high-volume operations.

Safety Considerations for Both Grinder Types

Slow speed grinders reduce the risk of overheating and flying debris by operating at lower RPMs, enhancing user safety during prolonged use. High speed grinders require more rigorous safety measures, such as protective guards and proper handling techniques, due to their greater potential for sparks and material ejection. Both grinder types necessitate wearing appropriate personal protective equipment (PPE) like safety goggles, gloves, and ear protection to prevent injuries and ensure safe operation.

Impact on Tool Sharpening and Longevity

Slow speed grinders produce less heat, reducing the risk of overheating and damaging the tool's temper during sharpening, thus preserving the blade's hardness and durability. High speed grinders can quickly remove material but generate excessive heat, which may lead to faster wear and a compromised edge. Choosing a slow speed grinder helps maintain your tools' longevity by ensuring a precise, cooler sharpening process.

Cost Comparison: Slow vs. High Speed Grinders

Slow speed grinders generally have a lower initial purchase cost compared to high speed grinders due to simpler designs and less advanced motor technology. Operational expenses for slow speed grinders tend to be lower because they consume less electricity and generate less heat, reducing maintenance and replacement part frequency. High speed grinders, although more expensive upfront, often deliver faster processing times, which can offset higher energy costs in high-volume industrial applications.

Maintenance and Durability Factors

Slow speed grinders typically require less frequent maintenance due to reduced heat generation and wear on components, enhancing their overall durability. High speed grinders tend to experience faster wear on bearings and brushes, necessitating more regular inspections and part replacements to maintain optimal performance. Choosing the right grinder for your needs depends on balancing maintenance demands with durability expectations, ensuring your equipment lasts longer and operates efficiently.

Conclusion: Choosing the Right Grinder for Your Workshop

Slow speed grinders produce less heat and preserve the material's integrity, making them ideal for precision tasks and delicate surfaces in your workshop. High speed grinders offer faster material removal and efficiency, suited for heavy-duty grinding and cutting jobs that demand speed. Your choice depends on balancing the need for accuracy with productivity to optimize workshop performance and tool longevity.

Slow speed grinder vs high speed grinder Infographic

libmatt.com

libmatt.com