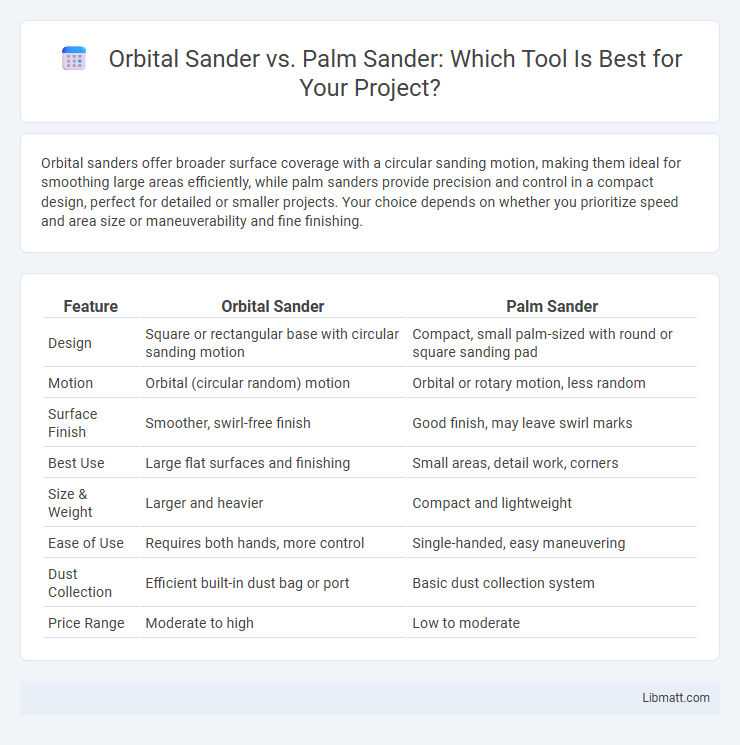

Orbital sanders offer broader surface coverage with a circular sanding motion, making them ideal for smoothing large areas efficiently, while palm sanders provide precision and control in a compact design, perfect for detailed or smaller projects. Your choice depends on whether you prioritize speed and area size or maneuverability and fine finishing.

Table of Comparison

| Feature | Orbital Sander | Palm Sander |

|---|---|---|

| Design | Square or rectangular base with circular sanding motion | Compact, small palm-sized with round or square sanding pad |

| Motion | Orbital (circular random) motion | Orbital or rotary motion, less random |

| Surface Finish | Smoother, swirl-free finish | Good finish, may leave swirl marks |

| Best Use | Large flat surfaces and finishing | Small areas, detail work, corners |

| Size & Weight | Larger and heavier | Compact and lightweight |

| Ease of Use | Requires both hands, more control | Single-handed, easy maneuvering |

| Dust Collection | Efficient built-in dust bag or port | Basic dust collection system |

| Price Range | Moderate to high | Low to moderate |

Introduction to Orbital and Palm Sanders

Orbital sanders utilize a random orbit motion that combines spinning and oscillating actions, resulting in a smooth finish ideal for large, flat surfaces. Palm sanders, smaller and lighter, operate with a consistent circular motion, making them perfect for detailed sanding in tight spaces and corners. Both tools are essential in woodworking and refinishing, but their unique designs cater to different sanding requirements.

Key Differences Between Orbital and Palm Sanders

Orbital sanders feature a round sanding pad that moves in a random orbit, providing a smooth finish ideal for fine woodworking and paint removal, while palm sanders have a smaller, square pad designed for detailed sanding in tight spaces. Orbital sanders typically offer higher power and larger sanding surfaces, making them suitable for heavy-duty sanding tasks compared to the more compact and lightweight palm sanders. The dust collection efficiency also differs, with orbital sanders often incorporating advanced vacuum systems, whereas palm sanders rely on simpler dust bags or basic collection methods.

How Orbital Sanders Work

Orbital sanders operate using a motor that rapidly moves a sanding pad in small, circular orbits, producing a smooth finish with minimal swirl marks. The random orbital motion prevents patterns from forming on the material surface, making it ideal for fine sanding tasks. This mechanism allows the sander to effectively remove paint, smooth wood, and prepare surfaces while reducing the risk of gouging.

How Palm Sanders Operate

Palm sanders operate using a small, motor-driven base that moves in a consistent circular or orbital motion to smooth surfaces efficiently. These sanders typically use fine-grit sandpaper attached via a hook-and-loop system, making them ideal for detail work and finishing tasks on wood, metal, and plastic. The compact design and ergonomic grip of palm sanders allow for precise control, reducing user fatigue during extended sanding sessions.

Pros and Cons of Orbital Sanders

Orbital sanders offer a versatile sanding experience with rapid, circular motion that efficiently smooths surfaces while minimizing swirl marks, making them ideal for larger projects. They are lightweight and easy to control, reducing user fatigue, but their aggressive sanding can sometimes remove too much material if not handled carefully. Your choice depends on the balance between speed and precision, as orbital sanders excel in fast material removal but lack the fine detail control of palm sanders.

Pros and Cons of Palm Sanders

Palm sanders offer excellent control and ease of use, making them ideal for detailed sanding tasks and tight spaces. Their lightweight design reduces user fatigue during prolonged use, but the smaller sanding surface limits efficiency on large projects. You may find palm sanders less powerful than orbital sanders, which can affect their performance on heavy material removal.

Best Use Cases for Orbital Sanders

Orbital sanders excel in medium to large surface sanding projects, such as smoothing wooden decks, furniture tops, and walls, where uniform finish and speed are essential. Their round sanding pad uses a random orbit pattern, reducing swirl marks and providing efficient material removal on flat or slightly curved surfaces. Ideal for tasks requiring both rough and fine sanding, orbital sanders deliver versatile performance across woodworking, refinishing, and finishing applications.

Ideal Projects for Palm Sanders

Palm sanders are ideal for small to medium-sized woodworking projects requiring precision and smooth finishes, such as furniture refinishing, cabinetry, and detailed trim work. They excel in sanding flat surfaces and contours with superior control due to their compact size and lightweight design. Your choice of a palm sander ensures efficient, fine sanding on intricate or delicate surfaces without gouging or over-sanding.

Choosing the Right Sander for Your Needs

An orbital sander offers a larger sanding surface and is ideal for smoothing broad, flat areas, while a palm sander provides more control for detailed work and tight spaces. Your choice depends on the project's scale and precision requirements, with orbital sanders excelling in heavy material removal and palm sanders suited for fine finishing. Understanding these differences ensures you select the right tool to achieve a professional, smooth finish efficiently.

Conclusion: Which Sander Is Better?

An orbital sander offers superior efficiency for larger, flat surfaces due to its random orbital motion that reduces swirl marks and provides a smoother finish. A palm sander is better suited for precision work and smaller, detailed areas because of its compact size and ease of handling. Your choice depends on the project size and finish quality, with the orbital sander being ideal for extensive sanding tasks and the palm sander excelling in detailed, controlled applications.

Orbital sander vs palm sander Infographic

libmatt.com

libmatt.com