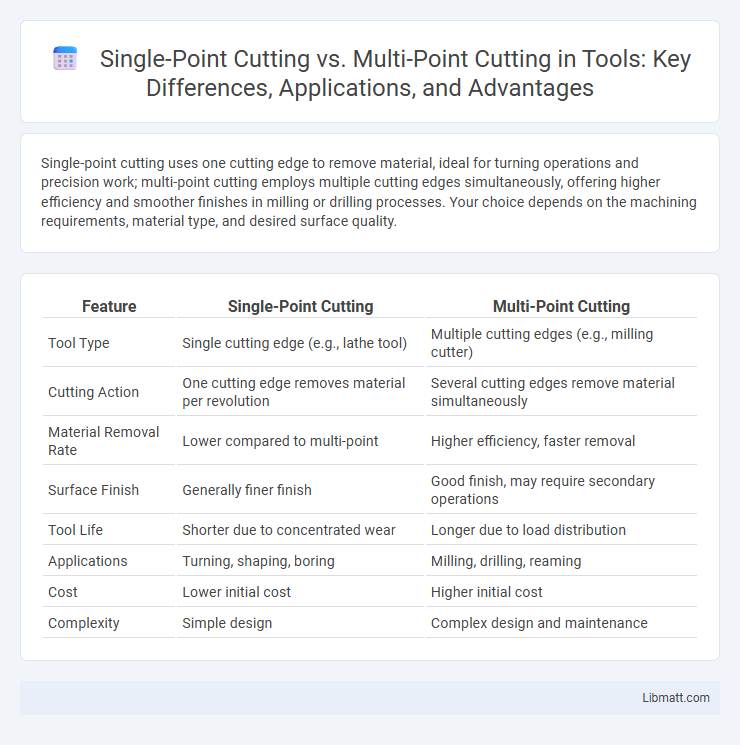

Single-point cutting uses one cutting edge to remove material, ideal for turning operations and precision work; multi-point cutting employs multiple cutting edges simultaneously, offering higher efficiency and smoother finishes in milling or drilling processes. Your choice depends on the machining requirements, material type, and desired surface quality.

Table of Comparison

| Feature | Single-Point Cutting | Multi-Point Cutting |

|---|---|---|

| Tool Type | Single cutting edge (e.g., lathe tool) | Multiple cutting edges (e.g., milling cutter) |

| Cutting Action | One cutting edge removes material per revolution | Several cutting edges remove material simultaneously |

| Material Removal Rate | Lower compared to multi-point | Higher efficiency, faster removal |

| Surface Finish | Generally finer finish | Good finish, may require secondary operations |

| Tool Life | Shorter due to concentrated wear | Longer due to load distribution |

| Applications | Turning, shaping, boring | Milling, drilling, reaming |

| Cost | Lower initial cost | Higher initial cost |

| Complexity | Simple design | Complex design and maintenance |

Introduction to Cutting Operations in Machining

Single-point cutting involves a single cutting edge interacting with the workpiece, commonly used in turning and shaping operations for precise material removal. Multi-point cutting employs multiple cutting edges simultaneously, typical in milling and drilling, enabling higher material removal rates and improved surface finish. Understanding these fundamental cutting operations is essential for optimizing machining efficiency and selecting suitable tools based on application requirements.

Defining Single-Point Cutting Tools

Single-point cutting tools feature a single cutting edge used primarily in turning, shaping, and boring operations, offering precise control over material removal. These tools are designed for applications requiring high accuracy and fine finishes, such as lathe machining, where the cutting action occurs at a single point. Understanding the advantages of single-point cutting tools helps optimize your machining processes by reducing tool wear and improving surface quality.

Defining Multi-Point Cutting Tools

Multi-point cutting tools feature multiple cutting edges that simultaneously engage the workpiece, enhancing material removal rates and tool life compared to single-point cutting tools, which use only one cutting edge. Typical examples include milling cutters and drills, which distribute cutting forces across several points, reducing wear and improving surface finish. Your choice between single-point and multi-point tools depends on the specific machining operation, material, and desired productivity.

Key Differences Between Single-Point and Multi-Point Cutting

Single-point cutting tools use one cutting edge to remove material, typically applied in turning and shaping operations, offering precision on simpler geometries. Multi-point cutting tools feature multiple cutting edges, as seen in milling cutters and drills, enabling faster material removal and better surface finishes on complex shapes. Understanding the key differences in tool design, cutting forces, and chip formation helps optimize your machining process for efficiency and accuracy.

Advantages of Single-Point Cutting Tools

Single-point cutting tools offer precise control over material removal, making them ideal for turning, shaping, and boring operations that require high accuracy and fine surface finishes. Their simpler geometry reduces manufacturing costs and tool maintenance, enhancing overall machining efficiency. Single-point tools also allow for easy adjustment of cutting parameters, which improves flexibility in handling various materials and complex shapes.

Advantages of Multi-Point Cutting Tools

Multi-point cutting tools increase machining efficiency by distributing the cutting load across several cutting edges, reducing individual tool wear and extending tool life. They enhance surface finish and dimensional accuracy due to the balanced cutting forces and reduced vibration during operation. Multi-point tools also enable higher material removal rates and are suitable for complex shapes, leading to improved productivity in manufacturing processes.

Typical Applications of Single-Point Cutting

Single-point cutting tools are predominantly used in turning operations, shaping, and boring where precision surface finish and dimensional accuracy are crucial. These tools excel in machining metals and materials that require intricate shapes and fine tolerances, such as engine components, shafts, and customized parts. Industries like automotive, aerospace, and tool-making rely heavily on single-point cutting for their critical, high-precision manufacturing processes.

Typical Applications of Multi-Point Cutting

Multi-point cutting tools are commonly used in machining processes such as milling, drilling, and broaching, where multiple cutting edges engage the material simultaneously for efficient material removal. These tools optimize productivity in high-volume manufacturing by distributing cutting forces across several edges, reducing tool wear and improving surface finish. Understanding your specific application requirements can help determine if multi-point cutting will enhance machining efficiency and part quality.

Performance Comparison: Efficiency and Surface Finish

Single-point cutting tools offer high precision and superior surface finish due to their focused cutting edge, making them ideal for detailed work and finishing passes. Multi-point cutting tools, such as milling cutters, provide greater efficiency in material removal rates by distributing the cutting load across multiple edges, which reduces individual tool wear and increases productivity. While single-point tools excel in achieving fine surface finishes, multi-point tools deliver enhanced efficiency for bulk material removal and roughing operations.

Selecting the Right Cutting Tool for Specific Machining Tasks

Single-point cutting tools excel in precision turning, shaping, and finishing operations, offering better control over surface finish and dimensional accuracy. Multi-point cutting tools, such as drills and milling cutters, enhance productivity in material removal by distributing the load across several cutting edges, ideal for high-volume machining. Selecting the right tool depends on factors like workpiece material, required tolerance, cutting speed, and tool life, ensuring optimal performance and cost-efficiency in machining processes.

Single-point cutting vs multi-point cutting Infographic

libmatt.com

libmatt.com