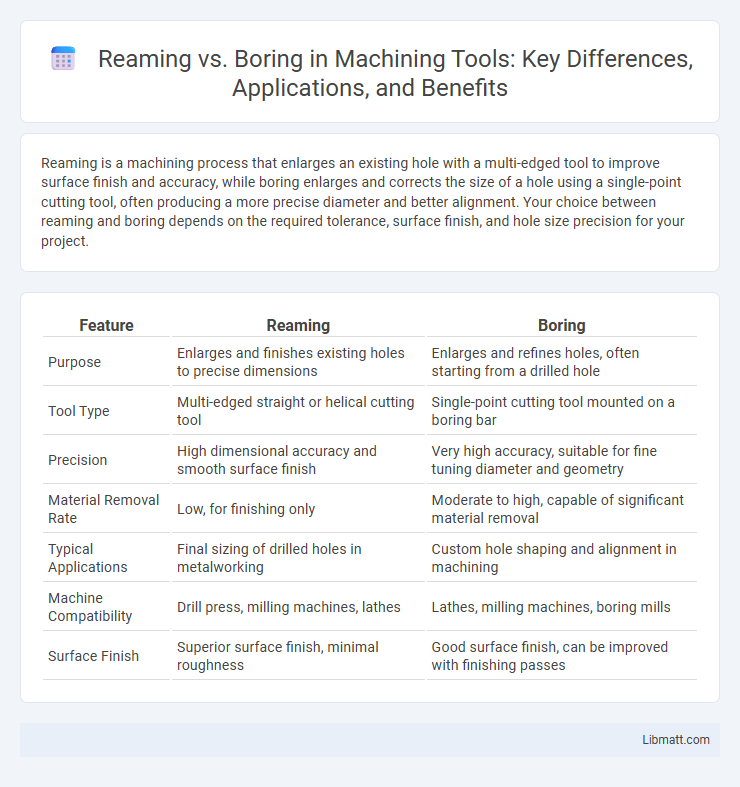

Reaming is a machining process that enlarges an existing hole with a multi-edged tool to improve surface finish and accuracy, while boring enlarges and corrects the size of a hole using a single-point cutting tool, often producing a more precise diameter and better alignment. Your choice between reaming and boring depends on the required tolerance, surface finish, and hole size precision for your project.

Table of Comparison

| Feature | Reaming | Boring |

|---|---|---|

| Purpose | Enlarges and finishes existing holes to precise dimensions | Enlarges and refines holes, often starting from a drilled hole |

| Tool Type | Multi-edged straight or helical cutting tool | Single-point cutting tool mounted on a boring bar |

| Precision | High dimensional accuracy and smooth surface finish | Very high accuracy, suitable for fine tuning diameter and geometry |

| Material Removal Rate | Low, for finishing only | Moderate to high, capable of significant material removal |

| Typical Applications | Final sizing of drilled holes in metalworking | Custom hole shaping and alignment in machining |

| Machine Compatibility | Drill press, milling machines, lathes | Lathes, milling machines, boring mills |

| Surface Finish | Superior surface finish, minimal roughness | Good surface finish, can be improved with finishing passes |

Introduction to Reaming and Boring

Reaming and boring are precision machining processes used to improve the accuracy and finish of holes in metalworking. Reaming involves using a multi-edged cutting tool called a reamer to enlarge and smooth pre-drilled holes with high dimensional accuracy and surface quality. Boring, on the other hand, employs a single-point cutting tool to enlarge and finish existing holes, often in larger diameters or deeper cavities, offering enhanced control over size and alignment.

Definition of Reaming

Reaming is a precision machining process used to enlarge and finish an existing hole to a specific diameter with high accuracy and a smooth surface finish. It involves the use of a multi-edged cutting tool called a reamer, which removes a small amount of material to improve hole geometry and dimensional tolerance. This process is essential in manufacturing applications requiring tight fits and enhanced hole quality.

Definition of Boring

Boring is a precise machining process used to enlarge or finish existing holes with high dimensional accuracy and improved surface finish. Unlike reaming, boring removes material from the interior of a hole to achieve tight tolerances and correct concentricity. Your choice between boring and reaming depends on the required hole quality and size adjustments in metalworking tasks.

Key Differences Between Reaming and Boring

Reaming enhances hole size accuracy and improves surface finish by using a multi-edge cutting tool, while boring enlarges and refines pre-existing holes with a single-point cutting tool to achieve precise diameter and alignment. Reaming generally corrects minor deviations from drilled holes, whereas boring addresses larger size adjustments and improves hole geometry, often allowing for deeper hole machining. Your choice depends on the required hole diameter precision, surface finish quality, and machining depth, as reaming is faster for fine finishing and boring offers greater flexibility for extensive hole modification.

Applications of Reaming

Reaming is primarily applied in precision machining to improve the dimensional accuracy and surface finish of drilled holes, especially in automotive and aerospace components. It is essential for creating smooth, round holes for dowel pins, bushings, and bearing seats, ensuring proper fit and function. The process is also widely used in metalworking industries to prepare holes for threading or assembly, minimizing wear and enhancing component longevity.

Applications of Boring

Boring is primarily used to enlarge existing holes with high precision, improving diameter accuracy and surface finish in metalworking and machining industries. It is essential for creating precise engine cylinders, bearing housings, and custom mechanical parts requiring tight tolerances. This process enables the correction of drilled hole imperfections and enhances the functionality of assembled components in aerospace, automotive, and manufacturing sectors.

Tools Used for Reaming and Boring

Reaming tools typically consist of multi-edged cutting instruments like hand reamers, machine reamers, and adjustable reamers designed to enlarge and improve the finish of existing holes. Boring tools include boring bars, boring heads, and single-point cutting tools mounted on lathes or milling machines to enlarge or finish holes with precise diameters and surface finishes. Both processes require specialized tooling materials such as high-speed steel (HSS) or carbide to maintain tool hardness and ensure accuracy during metal cutting operations.

Advantages of Reaming vs Boring

Reaming offers superior surface finish and tighter dimensional accuracy compared to boring, making it ideal for fine-tuning hole sizes in precision engineering. Your production efficiency increases due to faster cycle times and less tool wear during reaming processes. While boring excels in large diameter corrections, reaming provides enhanced hole quality with reduced vibration and better consistency.

Limitations of Each Process

Reaming is limited by its inability to correct major size errors, as it is designed for final finishing rather than heavy material removal, making it unsuitable for significantly undersized holes. Boring, while capable of enlarging and correcting misaligned holes, is constrained by higher tool costs and complexity, requiring precise machine setup and more time. Your choice depends on balancing the need for precision, cost, and the initial hole condition, as each method has distinct limitations in terms of accuracy, efficiency, and application scope.

Choosing Between Reaming and Boring

Choosing between reaming and boring depends on the desired hole accuracy, finish, and diameter tolerance. Reaming is ideal for fine-tuning hole size and improving surface finish after drilling, offering tight tolerance control typically within +-0.002 inches. Boring is preferred for enlarging existing holes or achieving precise dimensions with better concentricity and is suitable for larger diameter adjustments where rough cuts require more material removal.

Reaming vs boring Infographic

libmatt.com

libmatt.com