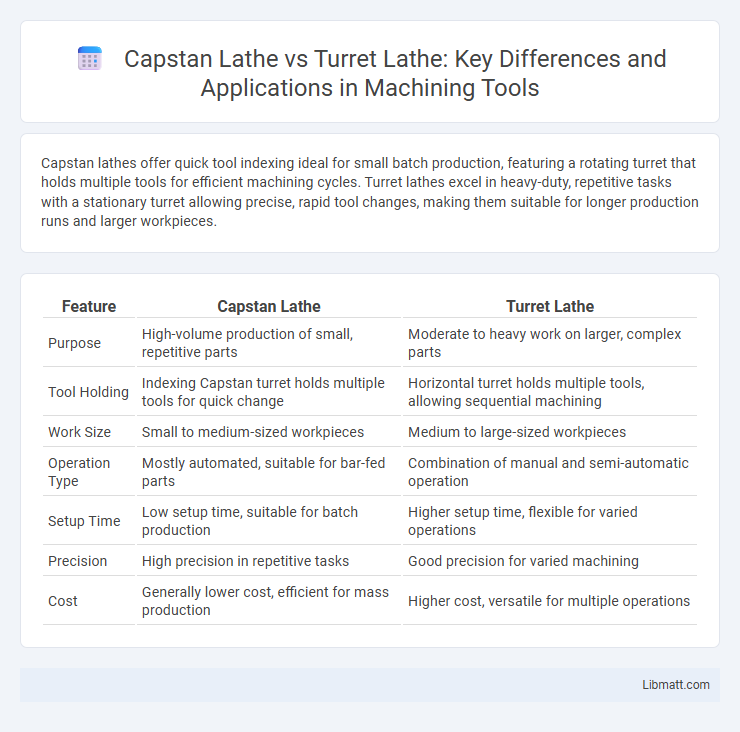

Capstan lathes offer quick tool indexing ideal for small batch production, featuring a rotating turret that holds multiple tools for efficient machining cycles. Turret lathes excel in heavy-duty, repetitive tasks with a stationary turret allowing precise, rapid tool changes, making them suitable for longer production runs and larger workpieces.

Table of Comparison

| Feature | Capstan Lathe | Turret Lathe |

|---|---|---|

| Purpose | High-volume production of small, repetitive parts | Moderate to heavy work on larger, complex parts |

| Tool Holding | Indexing Capstan turret holds multiple tools for quick change | Horizontal turret holds multiple tools, allowing sequential machining |

| Work Size | Small to medium-sized workpieces | Medium to large-sized workpieces |

| Operation Type | Mostly automated, suitable for bar-fed parts | Combination of manual and semi-automatic operation |

| Setup Time | Low setup time, suitable for batch production | Higher setup time, flexible for varied operations |

| Precision | High precision in repetitive tasks | Good precision for varied machining |

| Cost | Generally lower cost, efficient for mass production | Higher cost, versatile for multiple operations |

Introduction to Capstan and Turret Lathes

Capstan lathes and turret lathes are specialized machine tools designed for repetitive production tasks involving precise metal cutting and shaping. Both types feature a rotating turret head holding multiple tools, allowing for sequential operations without manual tool changes, significantly improving efficiency in mass production. Capstan lathes are typically smaller and suited for short batch production, while turret lathes handle longer production runs with more complex machining requirements.

Overview of Capstan Lathe

Capstan lathes are specialized machine tools designed for rapid, repetitive production, featuring a sliding turret that holds multiple tools and indexes automatically for efficient machining operations. These lathes excel in high-volume manufacturing environments where precision and speed are critical, offering reduced setup times compared to turret lathes. Your choice of a Capstan lathe ensures streamlined workflow and consistent part quality due to its automated tool indexing and tool-holding capabilities.

Overview of Turret Lathe

Turret lathes feature a rotating turret tool holder that allows multiple cutting operations without changing tools, enhancing efficiency in repetitive machining tasks. They are widely used for producing complex parts with precise, repeated cuts in industries such as automotive and aerospace. Their design supports quick tool changes and versatile operations, making them ideal for small to medium batch production.

Key Differences Between Capstan and Turret Lathes

Capstan lathes feature a ram mechanism that moves the tool holder back and forth, enabling faster tool changes for short production runs, while turret lathes use a rotating turret to hold multiple tools, ideal for longer and more complex machining sequences. The capstan lathe is generally more compact and suited for small to mid-sized batch production, whereas the turret lathe offers flexibility with multiple axes and tooling options ideal for heavy-duty, large-scale manufacturing. Your choice between these lathes depends on the production volume and complexity of the parts you need to machine.

Construction and Design Comparison

Capstan lathes feature a rotating turret mounted on the carriage, allowing rapid indexing and tool changes for repetitive production tasks, while turret lathes have a fixed turret integrated into a more robust carriage system suitable for heavier cutting operations. Capstan lathes are generally lighter with simpler construction, emphasizing speed and efficiency in medium-duty machining, whereas turret lathes incorporate heavier, more rigid frames designed to handle larger workpieces and higher cutting forces. The design differences influence their applications, with capstan lathes favored for small to medium batch production and turret lathes preferred for heavy-duty, high-precision tasks.

Applications and Use Cases

Capstan lathes are predominantly used for short production runs involving small to medium-sized parts, ideal for industries like automotive component manufacturing and jewelry making due to their quick tool changes and precision. Turret lathes excel in medium to large production volumes requiring complex multi-step operations, commonly employed in aerospace, heavy machinery, and firearm industries for producing shafts, pins, and threaded components. Both machines enhance efficiency in mass production but are selected based on the scale, complexity, and material of the workpieces.

Advantages of Capstan Lathes

Capstan lathes provide exceptional efficiency for short to medium production runs due to their quick tool indexing mechanism, which reduces setup time significantly. They offer precise control over threading and repetitive operations, enhancing accuracy and consistency in manufacturing. Compact design and ease of operation make capstan lathes ideal for small workshops and high-volume batch production.

Advantages of Turret Lathes

Turret lathes offer enhanced efficiency through their ability to hold multiple cutting tools simultaneously, enabling rapid tool changes and continuous machining without frequent stops. This capability significantly reduces cycle times and boosts productivity, especially in batch production environments. Your manufacturing process benefits from improved precision and versatility, as turret lathes can perform various operations such as drilling, threading, and turning in a single setup.

Limitations of Each Lathe Type

Capstan lathes have limitations in handling large workpieces due to their smaller size and fixed turret, restricting machining versatility and heavy-duty operations. Turret lathes, while accommodating larger and heavier workpieces, face challenges with complexity and setup time, making them less efficient for high-volume production of small parts. Both lathes require skilled operators to maximize precision and efficiency, as improper tooling or programming can lead to reduced productivity and increased wear.

Conclusion: Choosing the Right Lathe

Selecting the right lathe depends on your production needs and precision requirements. Capstan lathes excel in short-run, high-speed machining of smaller parts, providing quick tool changes and efficiency. Turret lathes are better suited for medium to long runs with versatile tooling options, allowing you to handle larger workpieces and more complex operations.

Capstan lathe vs turret lathe Infographic

libmatt.com

libmatt.com