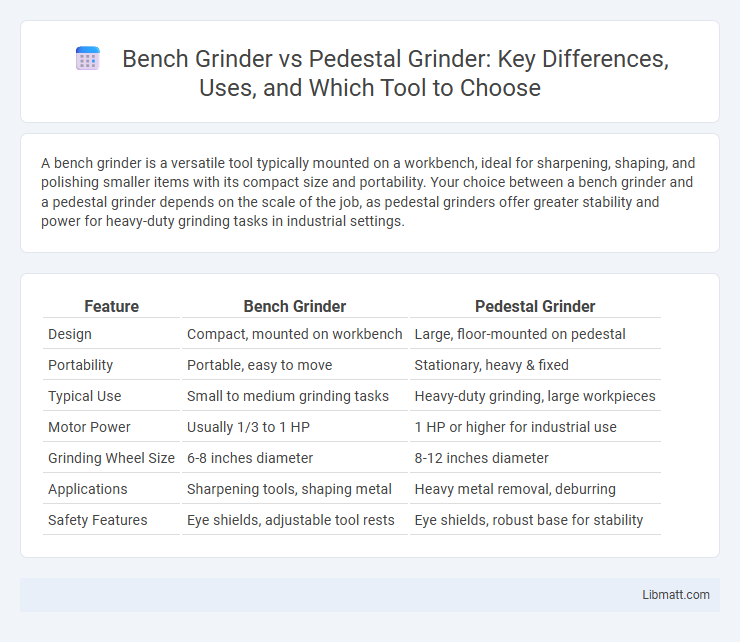

A bench grinder is a versatile tool typically mounted on a workbench, ideal for sharpening, shaping, and polishing smaller items with its compact size and portability. Your choice between a bench grinder and a pedestal grinder depends on the scale of the job, as pedestal grinders offer greater stability and power for heavy-duty grinding tasks in industrial settings.

Table of Comparison

| Feature | Bench Grinder | Pedestal Grinder |

|---|---|---|

| Design | Compact, mounted on workbench | Large, floor-mounted on pedestal |

| Portability | Portable, easy to move | Stationary, heavy & fixed |

| Typical Use | Small to medium grinding tasks | Heavy-duty grinding, large workpieces |

| Motor Power | Usually 1/3 to 1 HP | 1 HP or higher for industrial use |

| Grinding Wheel Size | 6-8 inches diameter | 8-12 inches diameter |

| Applications | Sharpening tools, shaping metal | Heavy metal removal, deburring |

| Safety Features | Eye shields, adjustable tool rests | Eye shields, robust base for stability |

Introduction to Bench Grinders and Pedestal Grinders

Bench grinders are compact, versatile tools typically mounted on workbenches, designed for sharpening, shaping, and polishing small metal parts with high precision. Pedestal grinders feature a larger, floor-mounted base offering enhanced stability and power, suitable for heavy-duty grinding tasks on larger workpieces. Both grinders utilize abrasive wheels but differ in size, application scope, and workspace integration, making them essential in metalworking shops for various grinding needs.

Key Differences Between Bench Grinders and Pedestal Grinders

Bench grinders are compact tools mounted on a workbench, ideal for smaller grinding tasks, while pedestal grinders feature a larger, floor-standing design suited for heavy-duty industrial applications. The key differences lie in size, portability, and power capacity, with pedestal grinders offering greater stability and torque for tougher materials. Your choice depends on workspace constraints and grinding requirements, as bench grinders are more accessible for home workshops, whereas pedestal grinders excel in professional settings.

Design and Construction Comparison

Bench grinders feature a compact design with a smaller base suited for mounting on workbenches, incorporating dual grinding wheels and adjustable tool rests for precision tasks. Pedestal grinders showcase a larger, free-standing construction with a robust base and extended height, offering greater stability and power for heavy-duty grinding applications. The pedestal model's design allows for enhanced vibration control and operator comfort during prolonged use compared to the bench grinder.

Common Applications of Bench Grinders

Bench grinders are commonly used for sharpening cutting tools, shaping metal parts, and removing rust or burrs in small to medium-sized workshops. These grinders excel in precision tasks such as blade sharpening and tool maintenance, making them ideal for mechanics, metalworkers, and hobbyists. Your workspace benefits from the bench grinder's compact design, allowing easy access for frequent, detailed grinding jobs.

Typical Uses for Pedestal Grinders

Pedestal grinders are commonly used in metal workshops for sharpening cutting tools, shaping metal parts, and removing rust or burrs from heavy-duty components. They offer stability and power for larger grinding tasks compared to bench grinders, making them ideal for continuous use in industrial environments. Typical applications include tool maintenance in fabrication shops and preparation of metal surfaces before welding or painting.

Power and Size Considerations

Bench grinders typically feature motors ranging from 1/4 to 1 horsepower, suitable for light to medium-duty tasks, and their compact size allows placement on workbenches for easy access. Pedestal grinders usually boast more powerful motors, often between 1 and 3 horsepower, designed for heavy-duty grinding operations, and their larger, freestanding structure provides greater stability. The choice between the two depends on workspace constraints and the intensity of grinding requirements, with pedestal grinders offering superior power and size for demanding industrial applications.

Safety Features and Precautions

Bench grinders and pedestal grinders both incorporate safety features such as eye guards, spark deflectors, and wheel covers to protect operators from flying debris and sparks. Pedestal grinders typically offer enhanced stability due to their floor-mounted design, reducing vibration and minimizing the risk of accidents during heavy-duty grinding tasks. Maintaining proper wheel speed, wearing personal protective equipment, and regularly inspecting grinding wheels are essential precautions for safe operation of both grinder types.

Pros and Cons of Bench Grinders

Bench grinders offer compact size, making them ideal for small workshops and easy portability, with typical wheel sizes ranging from 6 to 8 inches for versatile grinding tasks. Their primary advantage lies in precision work such as sharpening tools and shaping metal edges, though they may lack the power and stability of larger pedestal grinders for heavy-duty grinding. Your choice depends on tasks requiring fine detail versus continuous, high-intensity industrial use.

Advantages and Disadvantages of Pedestal Grinders

Pedestal grinders offer the advantage of a sturdy, stable base that ensures precision and safety during heavy-duty grinding tasks, making them ideal for workshops requiring sustained use. Their larger wheel size provides efficient material removal, but they can be less portable and require more floor space compared to bench grinders. Your workshop setup and mobility needs will determine if the pedestal grinder's robust design outweighs these disadvantages.

How to Choose Between a Bench Grinder and a Pedestal Grinder

Choosing between a bench grinder and a pedestal grinder depends on workspace constraints, job requirements, and portability needs. Bench grinders are compact, ideal for small workshops, and suitable for light to medium grinding tasks, whereas pedestal grinders offer greater stability and power for heavy-duty grinding on larger workpieces. Consider factors like motor horsepower, wheel size, and mounting options to select the right grinder for precision and efficiency in metalworking or sharpening applications.

Bench grinder vs pedestal grinder Infographic

libmatt.com

libmatt.com