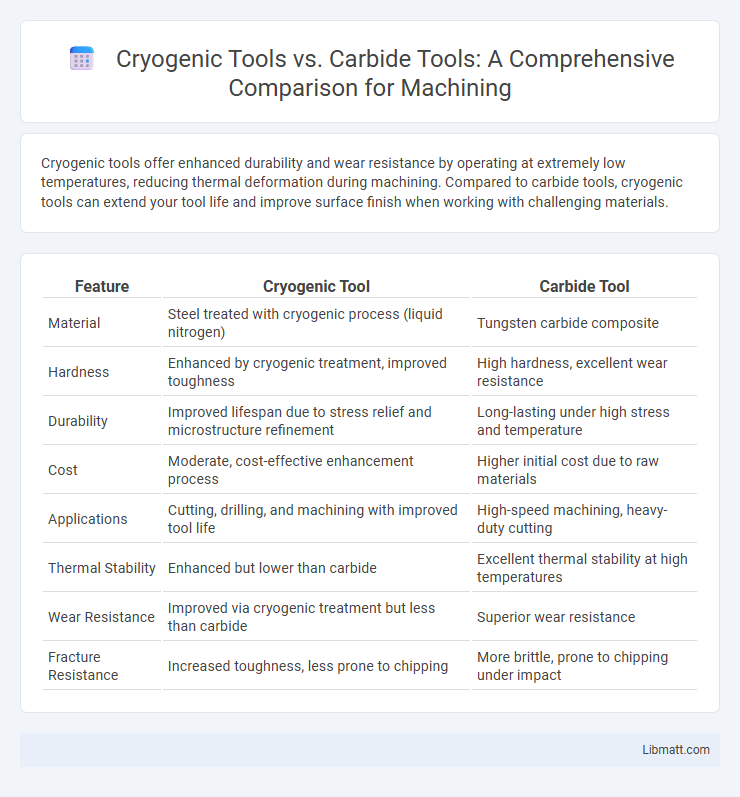

Cryogenic tools offer enhanced durability and wear resistance by operating at extremely low temperatures, reducing thermal deformation during machining. Compared to carbide tools, cryogenic tools can extend your tool life and improve surface finish when working with challenging materials.

Table of Comparison

| Feature | Cryogenic Tool | Carbide Tool |

|---|---|---|

| Material | Steel treated with cryogenic process (liquid nitrogen) | Tungsten carbide composite |

| Hardness | Enhanced by cryogenic treatment, improved toughness | High hardness, excellent wear resistance |

| Durability | Improved lifespan due to stress relief and microstructure refinement | Long-lasting under high stress and temperature |

| Cost | Moderate, cost-effective enhancement process | Higher initial cost due to raw materials |

| Applications | Cutting, drilling, and machining with improved tool life | High-speed machining, heavy-duty cutting |

| Thermal Stability | Enhanced but lower than carbide | Excellent thermal stability at high temperatures |

| Wear Resistance | Improved via cryogenic treatment but less than carbide | Superior wear resistance |

| Fracture Resistance | Increased toughness, less prone to chipping | More brittle, prone to chipping under impact |

Introduction to Cryogenic and Carbide Tools

Cryogenic tools use ultra-low temperature cooling techniques to enhance tool life and reduce wear during machining, contrasting with carbide tools which rely on the hardness and heat resistance of tungsten carbide material. Cryogenic cooling improves thermal stability and reduces friction, while carbide tools provide superior cutting performance and durability in high-speed applications. Understanding these differences helps you select the optimal tool for precision machining and extended operational efficiency.

Overview of Machining Tool Materials

Cryogenic tools utilize extremely low temperatures, typically involving liquid nitrogen, to enhance machining performance by reducing tool wear and improving material removal rates in metals like titanium and stainless steel. Carbide tools, composed primarily of tungsten carbide particles bonded with cobalt, offer high hardness and thermal resistance, making them suitable for high-speed cutting applications across a wide range of materials. Compared to carbide, cryogenic machining can extend tool life and improve surface finish by minimizing thermal degradation and mechanical stresses on the cutting edge during the machining process.

Working Principle of Cryogenic Tools

Cryogenic tools operate by using ultra-low temperatures, often achieved with liquid nitrogen, to cool the cutting edge during machining, which significantly reduces tool wear and thermal deformation. This cooling effect enhances the hardness and strength of the tool material, improving cutting efficiency and surface finish compared to carbide tools that rely primarily on their inherent material properties without active cooling. Your machining process benefits from extended tool life and improved performance when employing cryogenic tools over traditional carbide options.

Properties and Benefits of Carbide Tools

Carbide tools feature exceptional hardness and wear resistance due to their tungsten carbide composition, making them ideal for high-speed machining and maintaining sharp cutting edges. They withstand high temperatures better than conventional tools, improving tool life and surface finish quality on metals and alloys. Your machining efficiency increases as carbide tools require less frequent replacement and deliver consistent precision in cutting operations.

Performance Comparison: Cryogenic Tool vs Carbide Tool

Cryogenic tools significantly enhance tool life and cutting performance by maintaining lower operating temperatures, reducing thermal deformation and wear compared to carbide tools. Carbide tools excel in hardness and wear resistance but tend to degrade faster under high heat and stress without cooling assistance. Performance metrics show cryogenic cooling enables carbide tools to operate beyond conventional limits, improving surface finish and machining efficiency in high-speed and precision applications.

Cost Analysis: Investment and ROI

Cryogenic tools typically require higher initial investment due to advanced cooling systems but offer extended tool life and reduced downtime, leading to lower operational costs over time. Carbide tools have a lower upfront cost but wear out faster, increasing replacement frequency and affecting production efficiency. Evaluating ROI, cryogenic tools deliver better long-term value through improved durability and consistent machining performance despite the larger initial expenditure.

Applications in Modern Manufacturing

Cryogenic tools excel in high-precision aerospace and automotive manufacturing where extended tool life and reduced thermal distortion are critical, while carbide tools dominate general metal cutting, milling, and drilling applications due to their hardness and wear resistance. Your choice between cryogenic and carbide tools depends on the specific machining demands, such as temperature management and surface finish quality. Modern manufacturing increasingly integrates cryogenic cooling with carbide tooling to enhance productivity and tool longevity in high-speed and complex operations.

Tool Life and Wear Resistance

Cryogenic tools significantly extend tool life by reducing thermal degradation and minimizing wear during high-speed machining, outperforming conventional carbide tools in maintaining sharpness and hardness. The use of liquid nitrogen in cryogenic cooling lowers cutting temperatures, which enhances wear resistance and prevents premature tool failure, making it ideal for machining difficult materials like titanium and superalloys. Your choice of cryogenic tools can result in longer durability, fewer tool changes, and improved machining efficiency compared to standard carbide tools.

Environmental Impact and Sustainability

Cryogenic tools reduce environmental impact by utilizing liquid nitrogen cooling, eliminating the need for harmful cutting fluids and decreasing energy consumption during machining. Carbide tools, while durable, often require extensive coolant use that generates hazardous waste and increases environmental footprints. You can enhance sustainability in your manufacturing processes by choosing cryogenic tooling, which supports cleaner production and minimizes resource depletion.

Choosing the Right Tool for Your Process

Selecting between cryogenic tools and carbide tools depends on your machining requirements and material properties. Cryogenic tools excel in reducing thermal damage and extending tool life during high-speed or difficult-to-machine materials, while carbide tools offer superior hardness and wear resistance for general-purpose cutting. Evaluating factors like cutting temperature, material hardness, and desired surface finish ensures the right tool enhances process efficiency and product quality.

Cryogenic tool vs carbide tool Infographic

libmatt.com

libmatt.com