Quills are hollow feathers traditionally used as writing instruments by dipping the tip in ink, providing a natural, flexible nib ideal for calligraphy. Spindles, by contrast, are tools used in spinning to twist fibers into thread or yarn, focusing on textile production rather than writing.

Table of Comparison

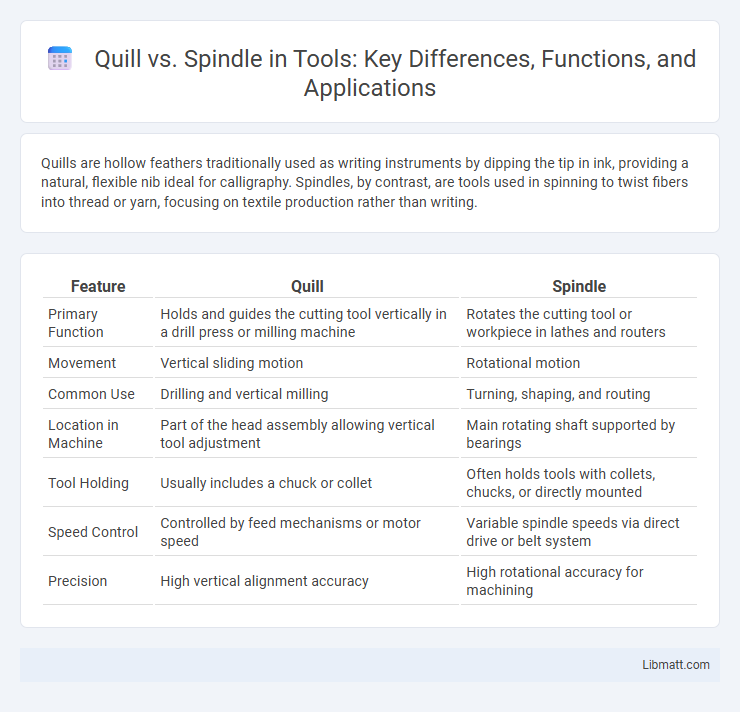

| Feature | Quill | Spindle |

|---|---|---|

| Primary Function | Holds and guides the cutting tool vertically in a drill press or milling machine | Rotates the cutting tool or workpiece in lathes and routers |

| Movement | Vertical sliding motion | Rotational motion |

| Common Use | Drilling and vertical milling | Turning, shaping, and routing |

| Location in Machine | Part of the head assembly allowing vertical tool adjustment | Main rotating shaft supported by bearings |

| Tool Holding | Usually includes a chuck or collet | Often holds tools with collets, chucks, or directly mounted |

| Speed Control | Controlled by feed mechanisms or motor speed | Variable spindle speeds via direct drive or belt system |

| Precision | High vertical alignment accuracy | High rotational accuracy for machining |

Introduction to Quill and Spindle

Quill and spindle are essential components in machining and woodworking, with the quill referring to a hollow shaft enabling vertical movement of the drill head, while the spindle is the rotating axis that holds the cutting tool or workpiece. Quills provide precise control in drill presses by allowing fine vertical adjustments, whereas spindles transmit torque and rotational motion from the motor to the cutting tool. Understanding the distinct roles of quill and spindle enhances machine operation accuracy and efficiency in industrial and manual machining processes.

Key Differences Between Quill and Spindle

The key differences between a quill and a spindle lie in their structure and function: a quill is a hollow cylindrical component that allows vertical movement and houses the spindle, while the spindle is a solid shaft that rotates to drive cutting tools or workpieces. Quills are commonly found in drill presses and milling machines to provide feed adjustment, whereas spindles directly transmit torque and rotational motion. Understanding these distinctions helps optimize your machine setup for precision and efficiency in machining operations.

Structural Design Comparison

Quills feature a hollow, cylindrical design that allows for easy tool changes and precise alignment, making them ideal for lightweight applications. Spindles, on the other hand, boast a more robust, solid structure that provides greater rigidity and stability, suitable for heavy-duty machining and high-speed operations. Understanding the structural differences between quill and spindle mechanisms can help optimize Your machine's performance and durability.

Functional Roles in Machinery

Quills serve as protective outer sleeves that hold and align rotating shafts, ensuring precise transmission of torque within machinery, while spindles function as the central rotating axis that supports and drives cutting tools or workpieces in equipment such as lathes and milling machines. The quill's design facilitates axial movement and stability, enabling fine adjustments and smooth operation, whereas the spindle is engineered for high-speed rotation and accurate positioning critical to machining accuracy. Distinguishing these components by their roles clarifies their importance in maintaining mechanical integrity and performance during manufacturing processes.

Precision and Accuracy: Quill vs Spindle

Quills provide less precision and accuracy compared to spindles due to potential play and looseness in the quill mechanism, which can cause slight movement during machining tasks. Spindles offer higher rigidity and stability, ensuring consistent and accurate tool positioning for fine detail work. Your projects requiring tight tolerances benefit significantly from the enhanced precision of spindle-driven systems.

Applications in Various Industries

Quill drives are commonly used in printing presses and textile machinery for precise rotational motion, while spindle drives are essential in CNC machines and woodworking tools for high-speed and accurate cutting operations. Your manufacturing processes benefit from quills' ability to handle torque variations, whereas spindles excel in applications requiring high rigidity and speed. Both components are integral across automotive, aerospace, and electronics industries, adapting to specific operational demands.

Advantages of Using a Quill

Quill mechanisms offer precise vertical movement control, making them ideal for tasks requiring fine adjustments, such as drilling and milling. Their compact design allows for easy integration into various machine tools, enhancing versatility and efficiency. You benefit from improved accuracy and smoother operation when using a quill over a spindle for depth-sensitive machining processes.

Benefits of a Spindle Mechanism

A spindle mechanism offers enhanced precision and smoother operation compared to a quill, making it ideal for high-accuracy milling and drilling tasks. Its rigid design reduces deflection and wear, extending tool life and improving work quality. By choosing a spindle, you ensure greater consistency in your machining processes and better overall efficiency.

Choosing Between Quill and Spindle

Choosing between a quill and spindle depends on your machining needs and precision requirements. A quill allows for fine, vertical adjustments during drilling or milling, providing versatility in depth control, whereas a spindle offers higher rigidity and rotational accuracy, ideal for heavy-duty or high-speed operations. Understanding your project's demands ensures you select the tool that maximizes efficiency and accuracy in your machining tasks.

Future Trends in Quill and Spindle Technology

Future trends in quill and spindle technology emphasize increased precision and higher rotational speeds supported by advancements in materials such as ceramics and composites, enhancing durability and thermal stability. Integration of smart sensors and IoT connectivity enables real-time monitoring of spindle conditions, predictive maintenance, and improved machining accuracy. Automation and adaptive control systems continue to evolve, driving efficiency in CNC machinery and reducing operational downtime across manufacturing industries.

Quill vs spindle Infographic

libmatt.com

libmatt.com