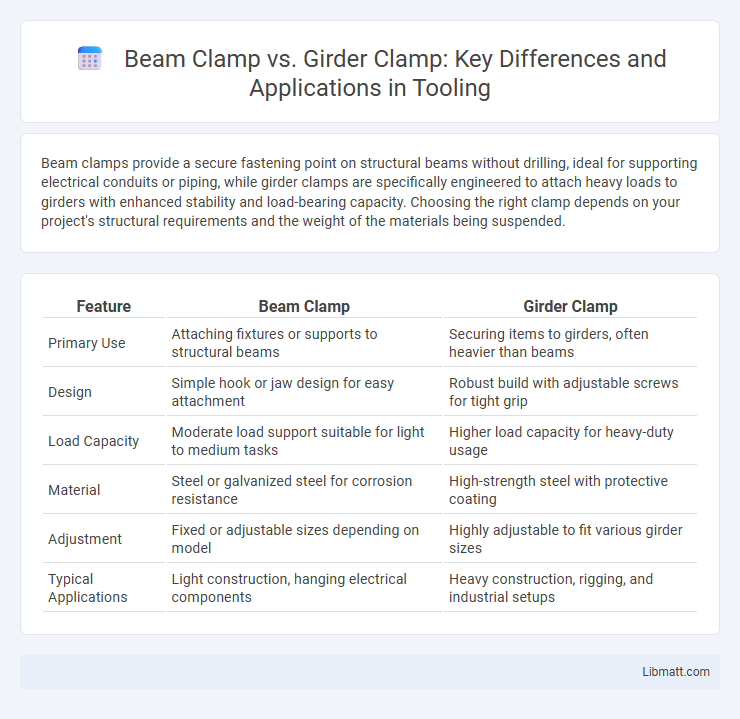

Beam clamps provide a secure fastening point on structural beams without drilling, ideal for supporting electrical conduits or piping, while girder clamps are specifically engineered to attach heavy loads to girders with enhanced stability and load-bearing capacity. Choosing the right clamp depends on your project's structural requirements and the weight of the materials being suspended.

Table of Comparison

| Feature | Beam Clamp | Girder Clamp |

|---|---|---|

| Primary Use | Attaching fixtures or supports to structural beams | Securing items to girders, often heavier than beams |

| Design | Simple hook or jaw design for easy attachment | Robust build with adjustable screws for tight grip |

| Load Capacity | Moderate load support suitable for light to medium tasks | Higher load capacity for heavy-duty usage |

| Material | Steel or galvanized steel for corrosion resistance | High-strength steel with protective coating |

| Adjustment | Fixed or adjustable sizes depending on model | Highly adjustable to fit various girder sizes |

| Typical Applications | Light construction, hanging electrical components | Heavy construction, rigging, and industrial setups |

Introduction to Beam Clamps and Girder Clamps

Beam clamps and girder clamps serve as essential components in structural engineering to securely fasten loads to steel beams and girders. Beam clamps attach directly to the flange of a beam, offering a reliable anchorage point without drilling or welding, while girder clamps are specifically designed for heavier duty applications on girders, providing enhanced load distribution and safety. Both clamp types facilitate efficient load hanging in construction and industrial settings, ensuring stability and ease of installation.

What is a Beam Clamp?

A beam clamp is a device designed to attach securely to structural steel beams, providing a stable anchor point for suspending loads such as pipes, conduit, or other equipment. Unlike girder clamps, beam clamps typically have a simple, adjustable design that allows for quick installation without drilling or welding. Understanding the specific load requirements and beam dimensions ensures Your safe and effective use of beam clamps in construction or industrial settings.

What is a Girder Clamp?

A girder clamp is a specialized fastening device designed to securely attach to large structural steel beams, such as girders, without the need for drilling or welding. It provides a strong, stable connection point for suspending loads like pipes, conduits, or cable trays, ensuring safety and ease of installation in construction and industrial settings. Your choice between a beam clamp and a girder clamp depends on the size and shape of the beam, with girder clamps specifically engineered for heavy-duty girders.

Key Differences Between Beam Clamps and Girder Clamps

Beam clamps and girder clamps differ primarily in their design and application, with beam clamps typically used for securing lighter loads to I-beams, while girder clamps are engineered for heavier-duty connections on large girders. The load capacity and size variations between the two affect their suitability for specific structural support tasks, ensuring safety and stability in construction projects. Your choice should consider the weight requirements and compatibility with the beam or girder profile to optimize structural efficiency.

Load Capacity Comparison

Beam clamps typically offer higher load capacities compared to girder clamps due to their robust construction and ability to distribute weight more evenly across structural beams. Girder clamps, while easier to install, generally support lighter loads and are suited for temporary or less demanding applications. When selecting between the two, engineers must assess the specific load requirements and structural integrity to ensure safety and compliance with industry standards.

Installation Methods and Ease

Beam clamps typically offer straightforward installation by fastening directly to the beam flange using a screw or bolt mechanism, allowing for quick positioning and secure attachment without the need for welding or drilling. Girder clamps often require more precise alignment and may involve bolted connections that accommodate larger structural elements, sometimes necessitating additional tools or hardware for proper fitment. Ease of installation favors beam clamps in scenarios demanding rapid setup, while girder clamps provide robust support suitable for heavy loads but may involve longer installation time due to complexity.

Safety Considerations for Each Clamp Type

Beam clamps provide secure attachment to structural beams by distributing load evenly, minimizing the risk of slippage or structural damage when properly installed according to manufacturer specifications. Girder clamps are engineered to handle heavier loads with robust locking mechanisms, reducing the likelihood of accidental disengagement and enhancing overall safety in high-capacity applications. Ensuring compatibility with beam size and load rating is critical for both clamp types to maintain structural integrity and prevent workplace accidents.

Typical Applications and Use Cases

Beam clamps are commonly used for securing conduit, pipes, and electrical fixtures to steel beams in construction and industrial settings, providing a quick and adjustable attachment method without drilling. Girder clamps are typically employed in heavy-duty applications requiring the suspension of HVAC systems, cable trays, and large mechanical equipment from structural girders, offering strong load-bearing support. Both clamps facilitate efficient installation in building infrastructure by accommodating various beam sizes and enabling non-destructive fastening.

Pros and Cons of Beam Clamps vs Girder Clamps

Beam clamps offer easy installation and strong load support, making them ideal for securing beams in construction and industrial applications; however, they may cause surface damage or require precise sizing to ensure a safe fit. Girder clamps provide enhanced stability on larger girders and distribute loads more evenly, reducing risk of slippage, but they tend to be bulkier and more complex to install. Your choice between beam clamps and girder clamps should consider the specific structural requirements, weight capacity, and ease of maintenance for your project.

Choosing the Right Clamp for Your Project

Beam clamps provide secure attachment to structural steel beams without drilling, making them ideal for temporary or adjustable supports, while girder clamps offer a stronger, more permanent connection suited for heavy-duty loads on girders. Your choice depends on load requirements, ease of installation, and whether the connection needs to be adjustable or fixed. Selecting the right clamp ensures safety and efficiency in your construction or rigging project.

Beam clamp vs girder clamp Infographic

libmatt.com

libmatt.com