A torque wrench provides precise control over the amount of torque applied to fasteners, ensuring accurate tightening without damage, essential for automotive and mechanical work. An impact wrench delivers high torque quickly using rotational impacts, making it ideal for loosening stubborn bolts but less suited for tasks requiring exact torque specifications; choose based on whether precision or power is your priority.

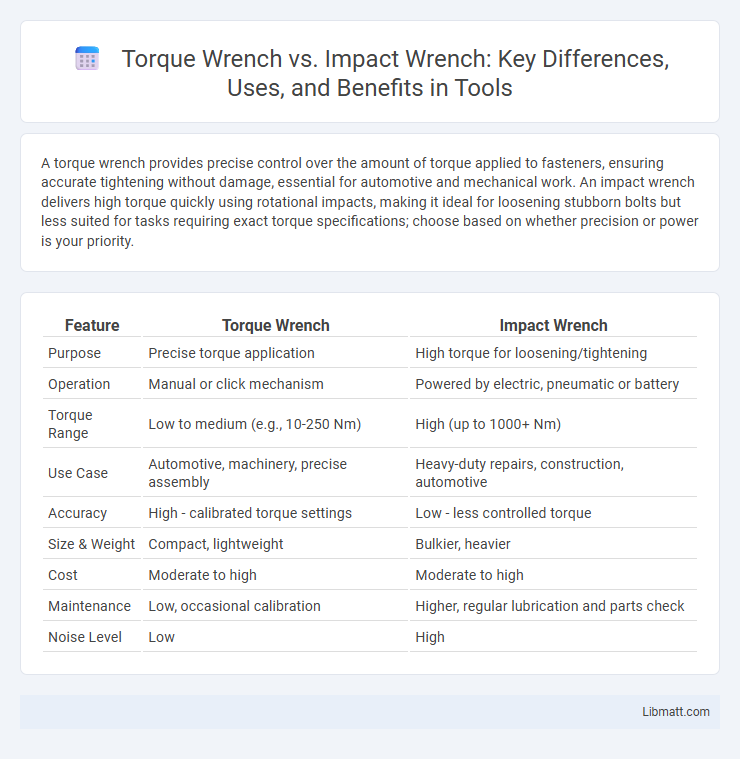

Table of Comparison

| Feature | Torque Wrench | Impact Wrench |

|---|---|---|

| Purpose | Precise torque application | High torque for loosening/tightening |

| Operation | Manual or click mechanism | Powered by electric, pneumatic or battery |

| Torque Range | Low to medium (e.g., 10-250 Nm) | High (up to 1000+ Nm) |

| Use Case | Automotive, machinery, precise assembly | Heavy-duty repairs, construction, automotive |

| Accuracy | High - calibrated torque settings | Low - less controlled torque |

| Size & Weight | Compact, lightweight | Bulkier, heavier |

| Cost | Moderate to high | Moderate to high |

| Maintenance | Low, occasional calibration | Higher, regular lubrication and parts check |

| Noise Level | Low | High |

Introduction to Torque Wrench vs Impact Wrench

Torque wrenches provide precise control over the tightening torque to prevent over-tightening or under-tightening of fasteners, making them essential for applications requiring accuracy, such as automotive repairs and machinery assembly. Impact wrenches deliver high torque output through rotational impacts, enabling rapid loosening or tightening of stubborn or large bolts in heavy-duty tasks like construction and industrial maintenance. Understanding the functional differences highlights that torque wrenches prioritize accuracy and calibration, while impact wrenches focus on power and speed.

What Is a Torque Wrench?

A torque wrench is a precision tool designed to apply a specific amount of torque to fasteners, ensuring accurate tightening without over or under-torquing. It is commonly used in automotive repair, machinery assembly, and engineering applications where precise torque specifications are critical for safety and performance. Unlike impact wrenches that rely on high-torque impacts for loosening or tightening, torque wrenches allow controlled application of torque, often featuring adjustable settings and calibrated scales for accuracy.

What Is an Impact Wrench?

An impact wrench is a powerful tool designed to deliver high torque output with minimal exertion by the user, using a hammering mechanism to tighten or loosen bolts and nuts quickly. Unlike a torque wrench, which is used for precision tightening to specific torque values, an impact wrench excels in fast, heavy-duty applications such as automotive repairs and construction. If you need rapid fastening or removal of hardware, an impact wrench provides efficiency and strength beyond manual tools.

Key Differences Between Torque and Impact Wrenches

Torque wrenches precisely measure and apply a specific amount of torque to fasteners, ensuring accurate tightening crucial for automotive and mechanical applications. Impact wrenches deliver high rotational force through rapid, concussive blows, making them ideal for loosening or tightening stubborn bolts quickly. Understanding the key differences between your torque wrench's controlled precision and the impact wrench's raw power can improve tool selection for your projects.

When to Use a Torque Wrench

A torque wrench is essential when precision tightening of bolts and fasteners is required to meet specific torque specifications, preventing over-tightening or under-tightening that can cause damage or safety issues. Use your torque wrench when working on engine components, suspension parts, or any application where manufacturer-recommended torque settings must be followed for reliable assembly and optimal performance. This tool ensures consistent and accurate torque application, which is crucial for maintaining the integrity of mechanical connections.

When to Use an Impact Wrench

An impact wrench is best used for tasks requiring high torque and speed, such as loosening stubborn lug nuts or heavy-duty bolts on vehicles and machinery. It excels in automotive repair, construction, and industrial applications where manual effort is insufficient or time constraints are critical. Your choice should favor an impact wrench when precision torque control is less important than efficient power delivery.

Pros and Cons of Torque Wrenches

Torque wrenches provide precise control over tightening force, essential for maintaining manufacturer specifications and preventing damage to delicate components, making them ideal for automotive and machinery applications. They are less suited for high-speed or repetitive tasks due to their manual operation, which can be time-consuming and physically demanding. While torque wrenches require calibration for accuracy and careful handling to avoid wear, their ability to deliver consistent torque makes them invaluable for safety-critical assemblies.

Pros and Cons of Impact Wrenches

Impact wrenches deliver high torque output, making them ideal for loosening stuck or rusted bolts quickly and efficiently, especially in automotive and heavy machinery applications. However, their powerful impacts can lead to over-tightening or damage to fasteners and threads, requiring careful use and torque control devices to prevent equipment wear or failure. Unlike torque wrenches, impact wrenches lack precise torque measurement, limiting their suitability for tasks requiring exact torque specifications.

Choosing the Right Tool for the Job

Selecting the right tool depends on the specific requirements of your project, with a torque wrench offering precise control over tightening torque essential for tasks like engine assembly or bicycle maintenance. An impact wrench delivers high torque output for quickly loosening or tightening bolts, making it ideal for heavy-duty automotive repairs or construction work. Consider your need for accuracy versus speed and power to decide between a torque wrench and an impact wrench for optimal results.

Conclusion: Torque Wrench vs Impact Wrench

Torque wrenches provide precise control over fastening torque, making them essential for applications requiring accuracy and preventing over-tightening, such as automotive repairs and machinery assembly. Impact wrenches deliver high torque quickly, ideal for loosening stubborn bolts and heavy-duty tasks but lack the fine torque control of torque wrenches. Choosing between the two depends on the need for precision versus speed and power in fastening operations.

Torque wrench vs impact wrench Infographic

libmatt.com

libmatt.com