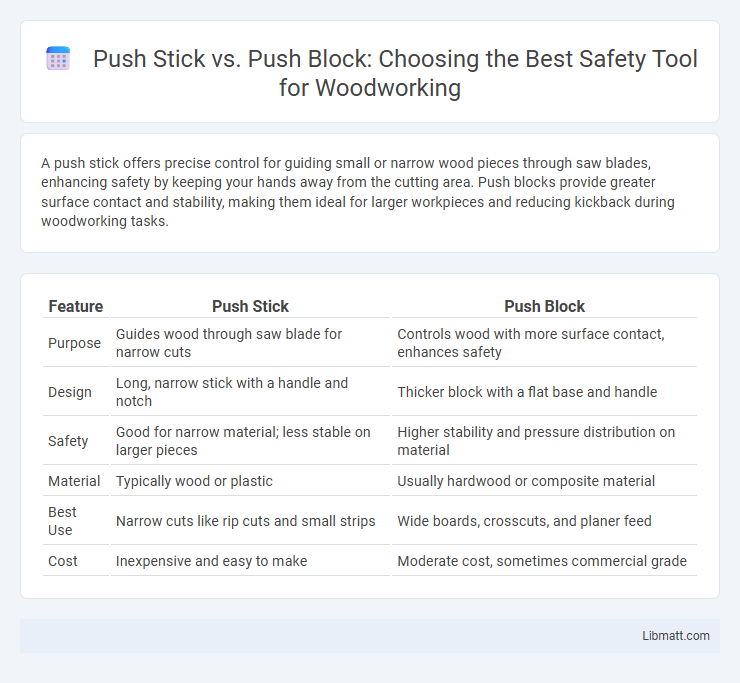

A push stick offers precise control for guiding small or narrow wood pieces through saw blades, enhancing safety by keeping your hands away from the cutting area. Push blocks provide greater surface contact and stability, making them ideal for larger workpieces and reducing kickback during woodworking tasks.

Table of Comparison

| Feature | Push Stick | Push Block |

|---|---|---|

| Purpose | Guides wood through saw blade for narrow cuts | Controls wood with more surface contact, enhances safety |

| Design | Long, narrow stick with a handle and notch | Thicker block with a flat base and handle |

| Safety | Good for narrow material; less stable on larger pieces | Higher stability and pressure distribution on material |

| Material | Typically wood or plastic | Usually hardwood or composite material |

| Best Use | Narrow cuts like rip cuts and small strips | Wide boards, crosscuts, and planer feed |

| Cost | Inexpensive and easy to make | Moderate cost, sometimes commercial grade |

Introduction to Push Sticks and Push Blocks

Push sticks and push blocks are essential safety tools in woodworking for guiding materials through cutting tools while keeping your hands protected. Push sticks are typically narrow and elongated, allowing precise control for thin or narrow stock, whereas push blocks feature a flat base with a handle, providing stability and better force distribution on wider pieces. Understanding the differences between these tools enhances your safety and efficiency during woodworking projects.

Defining Push Sticks: Features and Functions

Push sticks are essential woodworking safety tools designed to guide and control wood pieces while keeping Your hands at a safe distance from cutting blades. Typically made of wood or plastic, push sticks feature a narrow handle with a hooked or notch end to securely grip and push the material. Their primary function is to provide precision and stability during cutting, reducing the risk of kickback and injury.

What Are Push Blocks? Key Characteristics

Push blocks are safety tools used in woodworking to guide materials through cutting machines while keeping Your hands at a safe distance. They typically feature a flat, wide base made of durable, non-slip material and a handle or grip that allows for stable control and pressure application. Key characteristics include a low profile to maintain consistent contact with the workpiece and a sturdy construction to withstand repeated use.

Safety Benefits: Push Stick vs Push Block

Push sticks and push blocks both enhance woodworking safety by keeping your hands away from blades and cutting tools, but push blocks offer superior control and stability due to their larger gripping surface and ergonomic design. Push blocks reduce the risk of slipping and allow you to apply even pressure, which minimizes kickback hazards during cutting. Choosing the right tool enhances your safety by providing better protection tailored to different types of cut accuracy and material handling.

Precision and Control Compared

Push sticks offer greater precision for fine woodworking tasks due to their slim, pointed design that allows you to guide narrow pieces closely to the blade. Push blocks provide enhanced control and stability when working with larger or irregularly shaped stock, thanks to their broad, flat surface and ergonomic grip. Choosing the right tool depends on your project's needs, with push sticks excelling in detailed cuts and push blocks ensuring safer, steadier handling.

Best Applications for Push Sticks

Push sticks are best suited for guiding narrow or small workpieces safely through table saws and jointers, providing precise control and reducing the risk of kickback. They excel in applications requiring fine adjustments and close proximity to the cutting blade, making them ideal for detailed woodworking tasks. Push sticks offer enhanced finger protection and maneuverability, especially when working with thinner stock.

Optimal Uses of Push Blocks

Push blocks provide enhanced control and safety when guiding wood through power tools, making them ideal for use with table saws and jointers. Their larger surface area and ergonomic design distribute force evenly, reducing the risk of kickback and ensuring precise cuts. Push blocks excel in applications requiring stable pressure and protection of fingers during intricate woodworking tasks.

Material and Design Differences

Push sticks are typically made from durable hardwood or plastic, featuring a slender, elongated design with a notch for gripping materials safely during cutting. Push blocks are usually constructed from dense rubber or poly materials with a larger, flat base and a handle for applying even pressure and increased control on workpieces. The design differences emphasize push sticks' precision in guiding narrow cuts, while push blocks provide stability and protection when feeding larger or wider stock into saw blades.

User Experience: Comfort and Handling

Push blocks offer superior comfort with their larger surface area and ergonomic design, reducing hand fatigue during extended woodworking tasks. Push sticks provide more precision in tight spaces but may cause discomfort due to their smaller grip and less support. Your choice should balance the need for control and comfort based on the specific project requirements.

Choosing the Right Tool for Your Woodworking Projects

Selecting the right push stick or push block depends on the type of woodworking project and the level of control needed. Push sticks offer precise guidance for narrow stock and detailed cuts, while push blocks provide greater stability and safety for larger panels. Your choice should prioritize both accuracy and protection to ensure efficient and secure handling of materials during cutting.

Push stick vs push block Infographic

libmatt.com

libmatt.com