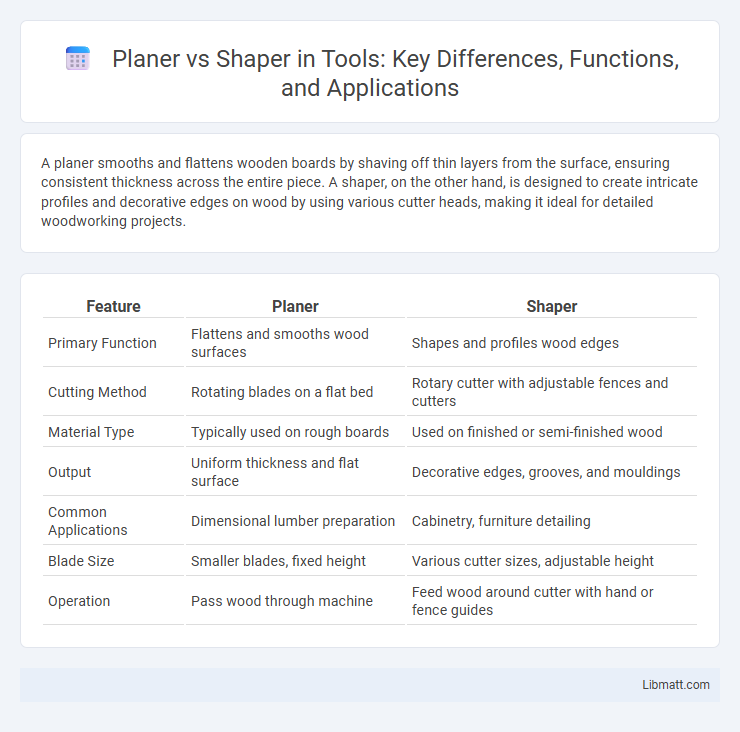

A planer smooths and flattens wooden boards by shaving off thin layers from the surface, ensuring consistent thickness across the entire piece. A shaper, on the other hand, is designed to create intricate profiles and decorative edges on wood by using various cutter heads, making it ideal for detailed woodworking projects.

Table of Comparison

| Feature | Planer | Shaper |

|---|---|---|

| Primary Function | Flattens and smooths wood surfaces | Shapes and profiles wood edges |

| Cutting Method | Rotating blades on a flat bed | Rotary cutter with adjustable fences and cutters |

| Material Type | Typically used on rough boards | Used on finished or semi-finished wood |

| Output | Uniform thickness and flat surface | Decorative edges, grooves, and mouldings |

| Common Applications | Dimensional lumber preparation | Cabinetry, furniture detailing |

| Blade Size | Smaller blades, fixed height | Various cutter sizes, adjustable height |

| Operation | Pass wood through machine | Feed wood around cutter with hand or fence guides |

Introduction to Planer and Shaper Machines

Planer machines are designed primarily for shaping large, flat surfaces by moving the workpiece back and forth against a stationary cutting tool, providing precise material removal on heavy and oversized workpieces. Shaper machines operate with a reciprocating single-point cutting tool that moves across the stationary workpiece, ideal for detailing smaller flat surfaces, grooves, and keyways with high accuracy. Understanding the differences in movement and applications of planer and shaper machines helps you select the right equipment for your machining needs.

Working Principle: Planer vs Shaper

A planer operates by moving the workpiece back and forth under a stationary cutting tool, allowing material removal to create flat surfaces on large or irregularly shaped objects. In contrast, a shaper uses a single-point cutting tool that moves linearly over a stationary workpiece, making it ideal for producing precise flat surfaces, slots, and grooves. The key distinction lies in the movement: planers shift the workpiece, while shapers move the tool.

Key Components of Planer and Shaper

A planer features a flat, adjustable table with a rotating cylindrical cutting blade beneath it, designed to smooth and level wooden boards to uniform thickness. A shaper includes a vertically oriented spindle capable of holding various interchangeable cutters, allowing intricate edge profiles and moldings. Understanding these key components helps you choose the right machine for precise woodworking tasks.

Types of Planer and Shaper Machines

Planer machines, primarily used for heavy-duty metal or wood shaping, come in types such as double housing planers, open-side planers, and pit planers, each designed for specific industrial applications requiring flat surfaces or grooves. Shaper machines vary mainly between crank shapers and hydraulic shapers, with crank shapers commonly used for simple shaping tasks while hydraulic shapers offer greater control and power for complex profiles. Understanding the differences in types allows manufacturers to select the appropriate machine based on material size, shape complexity, and production volume.

Application Areas: Planer vs Shaper

Planers excel in producing flat surfaces on large, heavy workpieces such as machine beds and structural components, making them ideal for heavy-duty, straight-line machining operations. Shapers specialize in cutting precise grooves, slots, and intricate contours on smaller or medium-sized parts, often used in tool rooms and manufacturing of mechanical parts. Both machines serve essential roles in metalworking and woodworking industries, with planers favoring surface machining and shapers targeting detailed shaping tasks.

Distinctive Features and Differences

Planers feature a flat bed and a stationary tool that moves over the workpiece, ideal for creating flat surfaces on large or irregularly shaped materials, while shapers use a single-point cutting tool that moves back and forth horizontally against a stationary workpiece, suited for intricate shaping tasks like grooves and slots. Planers typically handle larger workpieces with slower cutting speeds and greater precision over extended surfaces, whereas shapers excel in detailed contouring with faster tool strokes but are limited to smaller workpieces. The key difference lies in the type of motion and application: planers move the workpiece relative to a fixed tool, and shapers move the tool relative to a fixed workpiece.

Advantages of Using Planer Machines

Planer machines offer precise surface leveling and flattening on large workpieces, making them ideal for heavy-duty applications. Their capacity to handle irregular shapes and large sizes ensures consistent accuracy and smooth finishes without multiple setups. You benefit from enhanced productivity and reduced machining time when using planer machines in metalworking projects.

Benefits of Shaper Machines

Shaper machines provide precise and smooth surface finishes on metal workpieces, making them ideal for producing flat, angular, and contoured surfaces with high accuracy. They excel in creating complex shapes and internal gears that planer machines cannot efficiently handle, offering superior versatility in machining operations. The compact design and adjustable stroke length of shaper machines enable customized cutting, reducing material waste and enhancing productivity in manufacturing processes.

Limitations and Drawbacks

Planers often face limitations with thickness capacity and surface finish quality, making them less suitable for highly detailed or complex woodworking tasks. Shapers, while providing more precision for shaping edges and contours, can be limited by their smaller working area and higher operational skill requirements. Your choice should consider these drawbacks in relation to project complexity and desired finish quality.

Choosing the Right Machine: Planer or Shaper

Selecting the right woodworking machine depends on the project requirements and desired finish; a planer excels at flattening and thicknessing rough lumber quickly and uniformly, while a shaper is ideal for complex edge profiling and molding with interchangeable cutters. Planers optimize material preparation by producing even thickness, essential for precise joinery, whereas shapers provide versatility in creating decorative edges, grooves, and intricate shapes on wood pieces. Understanding the operational strengths of planers and shapers ensures efficient workflow and high-quality results in cabinetry, furniture making, or trim production.

Planer vs shaper Infographic

libmatt.com

libmatt.com