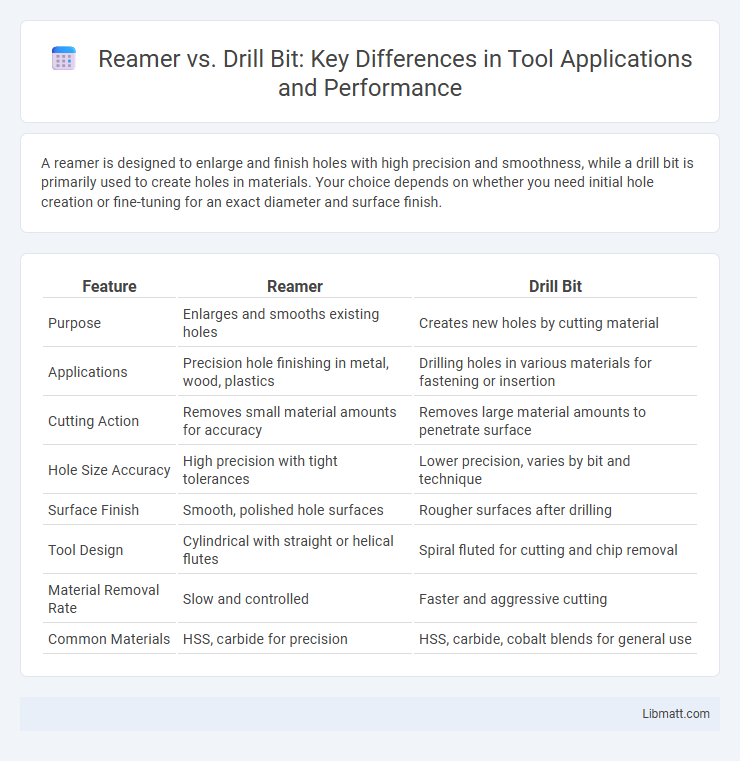

A reamer is designed to enlarge and finish holes with high precision and smoothness, while a drill bit is primarily used to create holes in materials. Your choice depends on whether you need initial hole creation or fine-tuning for an exact diameter and surface finish.

Table of Comparison

| Feature | Reamer | Drill Bit |

|---|---|---|

| Purpose | Enlarges and smooths existing holes | Creates new holes by cutting material |

| Applications | Precision hole finishing in metal, wood, plastics | Drilling holes in various materials for fastening or insertion |

| Cutting Action | Removes small material amounts for accuracy | Removes large material amounts to penetrate surface |

| Hole Size Accuracy | High precision with tight tolerances | Lower precision, varies by bit and technique |

| Surface Finish | Smooth, polished hole surfaces | Rougher surfaces after drilling |

| Tool Design | Cylindrical with straight or helical flutes | Spiral fluted for cutting and chip removal |

| Material Removal Rate | Slow and controlled | Faster and aggressive cutting |

| Common Materials | HSS, carbide for precision | HSS, carbide, cobalt blends for general use |

Understanding the Basics: What is a Reamer?

A reamer is a precision cutting tool designed to enlarge and smooth existing holes with high accuracy, improving surface finish and dimensional tolerance. Unlike a drill bit, which creates initial holes by cutting material from solid surfaces, a reamer is used after drilling to refine the hole diameter and ensure perfect roundness. Understanding the purpose of a reamer helps you achieve precise hole sizes essential for assembly and mechanical fit in machining processes.

Drill Bit Defined: Purpose and Function

A drill bit is a cutting tool designed to create cylindrical holes in various materials by rotating and removing material as it advances. It serves primarily for initial hole creation, ensuring precise size and shape according to the drilling requirements. Unlike reamers, drill bits focus on rapid penetration and rough hole formation rather than fine surface finishing or exact dimensional control.

Key Differences Between Reamers and Drill Bits

Reamers provide precision enlargement and finishing of existing holes, ensuring tight tolerances and smooth surface finishes, while drill bits are primarily designed for creating initial holes in various materials. Drill bits vary widely in size and type for different drilling applications, whereas reamers are typically used after drilling to improve hole accuracy and dimensional consistency. The cutting edges of a reamer are designed for fine material removal with minimal vibration, contrasting with the more aggressive cutting action of drill bits during hole creation.

Applications: When to Use a Reamer vs a Drill Bit

Choose a drill bit for creating initial holes in materials like metal, wood, or plastic, where precision sizing is less critical. Use a reamer after drilling to enlarge or finish an existing hole, achieving smooth, accurate dimensions and improved surface finish essential for fitting components. Your project benefits from a drill bit's versatility and speed during rough cutting, while a reamer excels in precision applications requiring tight tolerances.

Materials: Compatible Workpieces for Reamers and Drills

Reamers are designed to work on softer materials such as aluminum, brass, and mild steel, providing a smooth finish and precise hole sizing after drilling. Drill bits are compatible with a wider range of workpieces including harder metals like stainless steel, cast iron, and titanium, effectively creating initial holes. Selecting the appropriate tool depends on the material hardness and the desired hole accuracy in machining operations.

Precision and Tolerance: Accuracy Comparison

Reamers offer superior precision and tighter tolerance control compared to drill bits, ensuring hole diameters are accurate to within a few microns. Drill bits typically remove material faster but produce holes with rougher finishes and less dimensional accuracy, requiring subsequent reaming for exact specifications. The choice depends on the required tolerance level, with reamers preferred for high-accuracy applications in machining and assembly.

Types of Reamers and Drill Bits Explained

Reamers come in various types, including hand reamers, machine reamers, and adjustable reamers, each designed to finish holes with precision and improve surface finish. Drill bits vary widely as well, featuring common types like twist drills for general use, masonry bits for concrete, and spade bits for wood, tailored to different materials and drilling purposes. Understanding these types helps You select the right tool for accurate hole sizing and efficient material removal in your projects.

Tool Design and Cutting Mechanism

Reamers feature straight or helical cutting edges with precise dimensional control designed for fine finishing and enlarging existing holes, using a gradual cutting action that minimizes surface roughness and ensures tight tolerances. Drill bits have a tapered or cylindrical design with leading chisel edges and flutes that rapidly remove material to create new holes, relying on rotational and axial thrust forces for efficient penetration. The cutting mechanism of reamers emphasizes smooth material removal with consistent diameter accuracy, while drill bits prioritize aggressive cutting and chip evacuation for initial hole formation.

Durability and Maintenance Considerations

Reamers typically exhibit higher durability than drill bits due to their construction from high-speed steel or carbide, which withstands wear during precision enlargement of holes. Drill bits, often made from carbon steel or cobalt, can dull faster with frequent use, especially in tough materials, requiring regular sharpening or replacement. Maintenance of reamers involves careful cleaning and occasional honing to preserve accuracy, while drill bits demand frequent inspection and resharpening to maintain cutting performance.

Choosing the Right Tool for Your Project

Selecting between a reamer and a drill bit depends on the precision and finish required for your hole. Drill bits are ideal for creating initial holes quickly, while reamers excel at refining hole size and improving surface finish to exact specifications. Understanding your project's tolerance levels ensures you choose the right tool to achieve optimal accuracy and durability.

Reamer vs drill bit Infographic

libmatt.com

libmatt.com