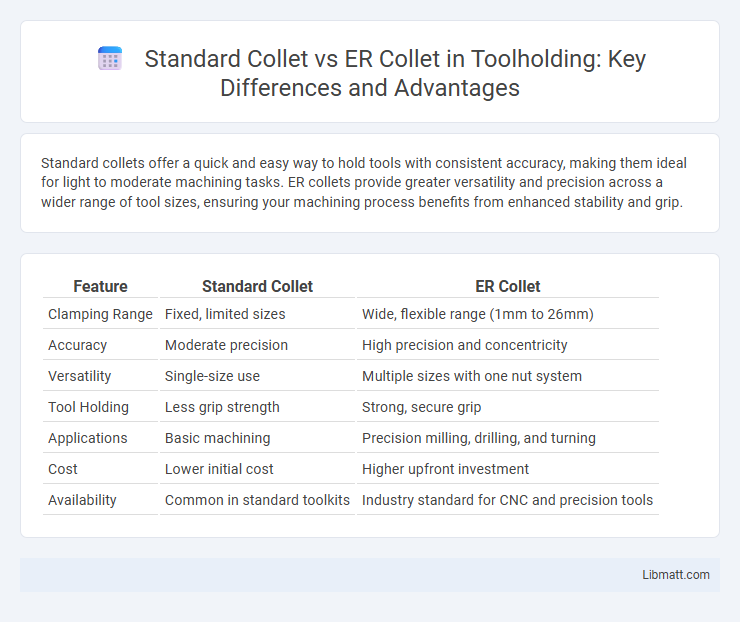

Standard collets offer a quick and easy way to hold tools with consistent accuracy, making them ideal for light to moderate machining tasks. ER collets provide greater versatility and precision across a wider range of tool sizes, ensuring your machining process benefits from enhanced stability and grip.

Table of Comparison

| Feature | Standard Collet | ER Collet |

|---|---|---|

| Clamping Range | Fixed, limited sizes | Wide, flexible range (1mm to 26mm) |

| Accuracy | Moderate precision | High precision and concentricity |

| Versatility | Single-size use | Multiple sizes with one nut system |

| Tool Holding | Less grip strength | Strong, secure grip |

| Applications | Basic machining | Precision milling, drilling, and turning |

| Cost | Lower initial cost | Higher upfront investment |

| Availability | Common in standard toolkits | Industry standard for CNC and precision tools |

Introduction to Collets: Standard vs ER

Standard collets, often known as drill chuck collets, provide basic clamping for round shanks and are typically used in low-precision applications. ER collets are high-precision, versatile tool holders designed for CNC machining, offering superior grip and concentricity across a range of tool diameters with their standardized taper and multiple sizes. The ER collet system's flexibility and accuracy make it the preferred choice in aerospace, automotive, and metalworking industries requiring precise tool holding.

What is a Standard Collet?

A Standard collet is a precision toolholder designed to securely clamp cutting tools or workpieces in machining operations, offering consistent concentricity and grip. It is typically simpler in design and used for basic toolholding applications with limited ranges of tool diameters. Your machining setup's choice between a Standard collet and an ER collet depends on the needed versatility, precision, and tool compatibility.

What is an ER Collet?

An ER collet is a standardized, highly versatile clamping tool designed to securely hold cutting tools or workpieces in machining applications, featuring a slotted, tapered cylindrical design that provides strong, uniform gripping force. Compared to standard collets, ER collets offer a wider size range, greater precision, and improved flexibility, making them ideal for CNC milling, drilling, and turning operations. Your machining setup benefits from ER collets' superior concentricity and reliable tool retention, enhancing accuracy and minimizing tool runout.

Design Differences: Standard vs ER Collet

Standard collets feature a simple slotted design that allows uniform compression around the tool shank, providing basic holding force primarily for cylindrical tools. ER collets employ a multi-slot, segmented design that enhances flexibility and gripping strength, accommodating a wider range of tool sizes and shapes with higher precision. The ER collet's advanced design improves concentricity and reduces runout, making it preferable for applications demanding tighter tolerances.

Clamping Range Comparison

Standard collets typically offer a narrower clamping range with fixed sizes designed for specific tool diameters, resulting in quick and precise holding but limited flexibility. ER collets provide a wider clamping range due to their tapered design, allowing them to accommodate multiple tool sizes within a single collet, enhancing versatility in machining applications. The ER collet system's adaptability reduces the need for frequent collet changes, improving workflow efficiency in environments requiring diverse tool sizes.

Precision and Accuracy: Which Collet Wins?

Standard collets typically offer high precision for specific tool sizes but lack versatility, while ER collets provide superior accuracy across a wide range of tool diameters due to their uniform clamping force and better concentricity. Your choice depends on application requirements, with ER collets excelling in tasks demanding consistent precision and minimal runout. In high-precision machining, ER collets often win by maintaining tight tolerances and reducing tool deflection.

Ease of Use: Changing and Setting Tools

Standard collets offer a straightforward clamping mechanism, making tool changes quick but may require precise alignment for secure gripping. ER collets provide higher versatility with a spring-like design that accommodates various tool sizes, allowing easier tool setting and reliable retention without frequent adjustments. The ER system's uniform clamping pressure reduces setup time and enhances repeatability in tool changing processes.

Applications for Standard and ER Collets

Standard collets are commonly used in general machining applications requiring moderate precision and are ideal for holding drill bits, reamers, and small end mills in lathes and drilling machines. ER collets offer higher precision and flexibility, supporting a wider range of tool diameters and are extensively applied in CNC milling, grinding, and high-speed machining for complex parts. Industries such as automotive, aerospace, and electronics benefit from ER collets due to their superior grip and reduced runout in critical applications.

Cost and Availability Analysis

Standard collets generally cost less upfront and are more widely available due to their longstanding use in basic machining tasks. ER collets, while slightly more expensive, offer greater versatility and precision, making them cost-effective in the long run for diverse tool holding needs. Your choice between the two should balance initial investment with availability based on the specific machining applications and frequency of use.

Choosing the Right Collet for Your Needs

Standard collets offer precision for specific tool sizes, ensuring a tight grip and reduced runout in applications requiring consistent tool holding. ER collets provide versatility with a wide clamping range, making them ideal for varied tooling options and quick changes. Assess your machining requirements carefully to select the collet that maximizes tool stability and efficiency for your projects.

Standard collet vs ER collet Infographic

libmatt.com

libmatt.com