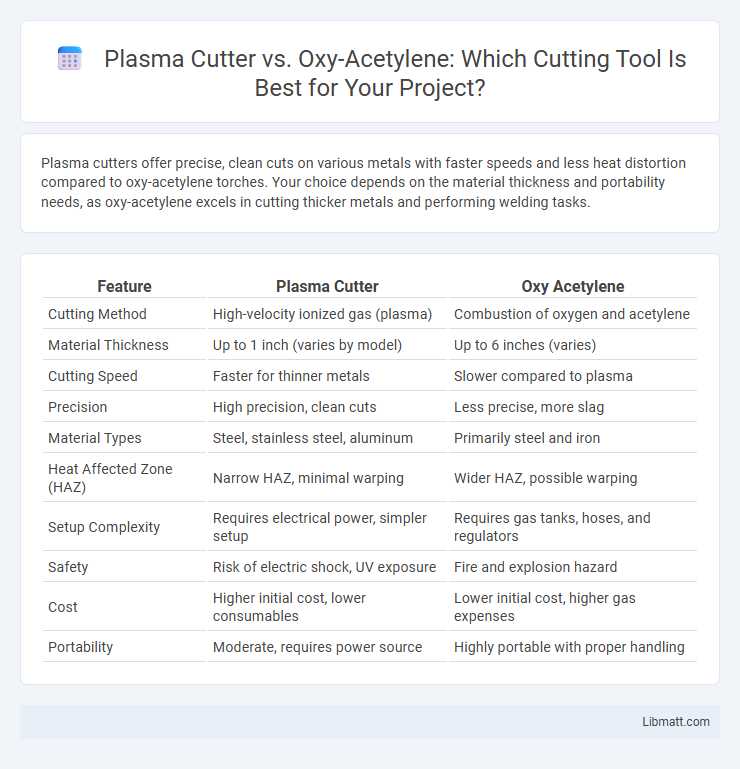

Plasma cutters offer precise, clean cuts on various metals with faster speeds and less heat distortion compared to oxy-acetylene torches. Your choice depends on the material thickness and portability needs, as oxy-acetylene excels in cutting thicker metals and performing welding tasks.

Table of Comparison

| Feature | Plasma Cutter | Oxy Acetylene |

|---|---|---|

| Cutting Method | High-velocity ionized gas (plasma) | Combustion of oxygen and acetylene |

| Material Thickness | Up to 1 inch (varies by model) | Up to 6 inches (varies) |

| Cutting Speed | Faster for thinner metals | Slower compared to plasma |

| Precision | High precision, clean cuts | Less precise, more slag |

| Material Types | Steel, stainless steel, aluminum | Primarily steel and iron |

| Heat Affected Zone (HAZ) | Narrow HAZ, minimal warping | Wider HAZ, possible warping |

| Setup Complexity | Requires electrical power, simpler setup | Requires gas tanks, hoses, and regulators |

| Safety | Risk of electric shock, UV exposure | Fire and explosion hazard |

| Cost | Higher initial cost, lower consumables | Lower initial cost, higher gas expenses |

| Portability | Moderate, requires power source | Highly portable with proper handling |

Introduction to Plasma Cutters and Oxy Acetylene

Plasma cutters utilize a high-velocity jet of ionized gas to melt and blow away metal, offering precise and efficient cutting for conductive materials. Oxy acetylene cutting relies on a chemical reaction of oxygen and acetylene gas to create a flame that heats metal until it reaches ignition temperature, then uses oxygen to oxidize and cut through the metal. Your choice between plasma cutters and oxy acetylene depends on factors like material type, cutting speed, thickness, and desired precision.

How Plasma Cutters Work

Plasma cutters operate by sending an electric arc through a gas, such as compressed air, to create a high-temperature plasma jet capable of melting and blowing away metal. This process enables precise, clean cuts on conductive materials like steel, aluminum, and stainless steel, offering faster cutting speeds and less heat distortion compared to oxy-acetylene torches. If you require efficient metal cutting with minimal finishing, a plasma cutter provides a more modern and versatile solution than traditional oxy-acetylene methods.

How Oxy Acetylene Torches Operate

Oxy acetylene torches operate by mixing oxygen and acetylene gases in a controlled flame that reaches temperatures around 3,500degC, enabling metal cutting and welding. The intense heat generated from the combustion causes localized melting of metal, and oxygen jets help blow away molten material, creating a precise cut. This process requires careful control of gas flow and pressure to maintain the flame stability essential for effective cutting performance.

Cutting Speed and Efficiency Comparison

Plasma cutters offer significantly faster cutting speeds and higher efficiency compared to oxy-acetylene torches, especially on thin to medium-thickness metals, with speeds up to 5 times quicker. Plasma cutting provides clean, precise cuts with minimal heat-affected zones, reducing post-cut cleanup and increasing productivity. Oxy-acetylene remains slower and less efficient, primarily suited for cutting thicker metals but produces rougher edges and requires more finishing work.

Material Versatility and Thickness Capabilities

Plasma cutters excel in cutting a wide range of electrically conductive metals, including steel, stainless steel, aluminum, brass, and copper, with thickness capacities typically ranging from 1/8 inch to over 1 inch depending on the model. Oxy-acetylene torches perform effectively on steel and other ferrous metals, with maximum thickness capabilities reaching up to 6 inches or more in skilled hands, but are less suited for non-ferrous metals like aluminum. Plasma cutting offers cleaner, faster cuts with higher precision across diverse materials, while oxy-acetylene provides deeper penetration for heavy steel sections but requires more post-cut cleanup.

Precision and Quality of Cuts

Plasma cutters deliver high precision and clean cuts with minimal heat distortion, enabling intricate shapes and fine details on metal surfaces. Oxy acetylene torches produce rougher edges due to wider flames and slower cutting speeds, often requiring additional finishing for quality results. You will achieve superior cut quality and accuracy with plasma cutting, especially on thinner materials and complex designs.

Safety Considerations and Risks

Plasma cutters operate with high-voltage electricity and compressed air, requiring proper insulation and protective gear to prevent electric shocks and burns. Oxy-acetylene torches involve open flames and combustible gases, posing risks of fire, explosions, and toxic gas exposure without adequate ventilation and flame-resistant clothing. Understanding these safety considerations helps you choose the right cutting tool while minimizing hazards in your workspace.

Equipment Cost and Maintenance

Plasma cutters generally have a higher initial equipment cost compared to oxy-acetylene torches but offer lower long-term maintenance expenses due to fewer consumables like gas cylinders and electrodes. Oxy-acetylene setups typically require frequent replacement of welding tips, regulators, and acetylene cylinders, increasing upkeep costs. Maintenance for plasma cutters mainly involves periodic electrode and nozzle replacement, making them more cost-effective for continuous or industrial use.

Portability and Ease of Use

Plasma cutters offer superior portability due to their compact design and lightweight construction, making them ideal for on-site cutting tasks. Their ease of use is enhanced by simple setup procedures and minimal preheating, allowing operators to achieve precise cuts quickly. In contrast, oxy-acetylene equipment requires heavy gas cylinders and careful handling, which can limit mobility and demand greater skill for safe operation.

Choosing the Right Cutting Tool for Your Needs

Plasma cutters provide precision, speed, and the ability to cut a wide range of metals up to several inches thick, making them ideal for industrial and detailed metalwork. Oxy-acetylene torches excel in cutting thicker metals and offer versatility with heating and welding capabilities but require more skill and safety precautions. Your choice depends on factors like metal thickness, cutting speed, portability, and the specific type of metalworking project you are undertaking.

Plasma cutter vs oxy acetylene Infographic

libmatt.com

libmatt.com