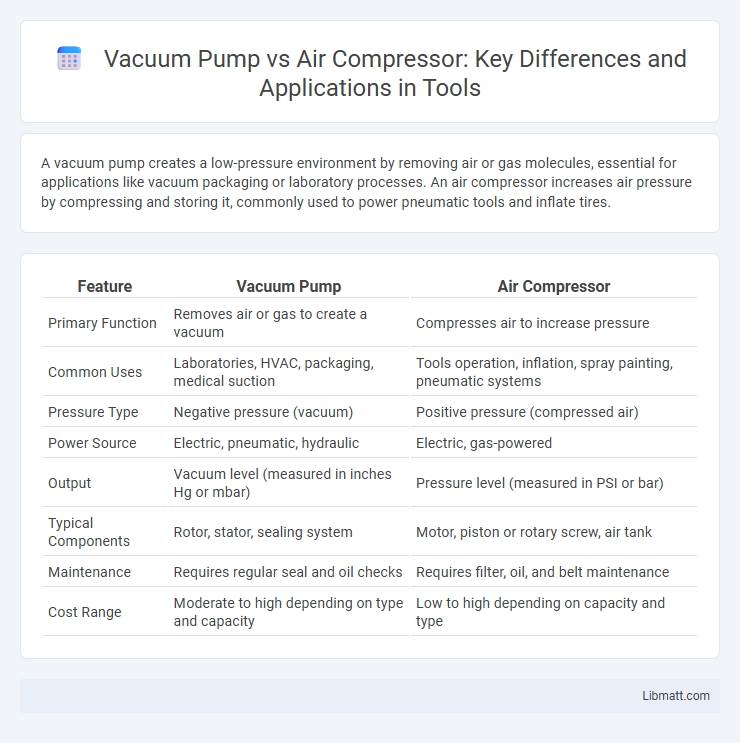

A vacuum pump creates a low-pressure environment by removing air or gas molecules, essential for applications like vacuum packaging or laboratory processes. An air compressor increases air pressure by compressing and storing it, commonly used to power pneumatic tools and inflate tires.

Table of Comparison

| Feature | Vacuum Pump | Air Compressor |

|---|---|---|

| Primary Function | Removes air or gas to create a vacuum | Compresses air to increase pressure |

| Common Uses | Laboratories, HVAC, packaging, medical suction | Tools operation, inflation, spray painting, pneumatic systems |

| Pressure Type | Negative pressure (vacuum) | Positive pressure (compressed air) |

| Power Source | Electric, pneumatic, hydraulic | Electric, gas-powered |

| Output | Vacuum level (measured in inches Hg or mbar) | Pressure level (measured in PSI or bar) |

| Typical Components | Rotor, stator, sealing system | Motor, piston or rotary screw, air tank |

| Maintenance | Requires regular seal and oil checks | Requires filter, oil, and belt maintenance |

| Cost Range | Moderate to high depending on type and capacity | Low to high depending on capacity and type |

Understanding the Basics: What Is a Vacuum Pump?

A vacuum pump is a device designed to remove gas molecules from a sealed volume, creating a partial vacuum by lowering the pressure inside the chamber. Unlike air compressors that increase air pressure to push air into a system, vacuum pumps work by reducing pressure to draw out air or gas, essential in applications like laboratory experiments, HVAC systems, and industrial processes. Understanding this fundamental difference helps in selecting the right equipment for tasks requiring controlled pressure environments or air removal.

Defining Air Compressors: Functions and Applications

Air compressors convert power into potential energy by compressing and storing air in tanks, enabling efficient delivery for various industrial, commercial, and residential applications. Common functions include powering pneumatic tools, inflating tires, and facilitating HVAC systems. Key industries utilizing air compressors encompass manufacturing, automotive repair, construction, and refrigeration, where consistent and pressurized airflow is essential.

Key Differences Between Vacuum Pumps and Air Compressors

Vacuum pumps and air compressors serve distinct functions: vacuum pumps remove air or gas molecules to create a vacuum, while air compressors increase air pressure by compressing atmospheric air. Key differences include their operational principles, with vacuum pumps generating negative pressure and air compressors producing positive pressure. Understanding these differences helps you select the right equipment for applications such as HVAC systems, pneumatic tools, or industrial processes.

How Vacuum Pumps Work: Underlying Principles

Vacuum pumps operate by removing gas molecules from a sealed volume to create a partial vacuum, utilizing mechanisms such as positive displacement, momentum transfer, or entrapment. These pumps rely on changes in pressure differentials to suction air or gases, often employing pistons, rotors, or diaphragms to achieve effective evacuation. Unlike air compressors that increase air pressure by compressing atmospheric air, vacuum pumps focus on lowering pressure to facilitate processes like material handling, drying, and scientific applications.

Air Compressor Mechanisms: How Do They Operate?

Air compressors operate by drawing in ambient air, then compressing it to increase pressure using mechanisms like pistons, rotary screws, or centrifugal impellers. These devices store compressed air in tanks, providing a steady supply for powering tools and equipment. Understanding the specific air compressor mechanism can optimize Your selection for applications needing high-pressure air delivery.

Common Uses of Vacuum Pumps in Industry

Vacuum pumps are widely used in industries such as pharmaceuticals, chemical processing, and food packaging to remove air and gases from sealed environments, ensuring product integrity and process efficiency. They play a critical role in applications like vacuum drying, degassing, and material handling where maintaining low pressure is essential. Your operation can benefit from vacuum pumps by enhancing precision in sensitive manufacturing processes and improving product quality.

Typical Applications of Air Compressors

Air compressors are commonly used in industrial manufacturing for powering pneumatic tools, spray painting, and inflating tires. They play a crucial role in construction sites for operating jackhammers and other heavy machinery. Additionally, air compressors are essential in automotive repair shops for tasks such as airbrushing and cleaning.

Energy Efficiency: Comparing Performance and Costs

Vacuum pumps generally consume less energy than air compressors when maintaining low-pressure environments, resulting in higher energy efficiency for specific applications like laboratory use or vacuum packaging. Air compressors typically require more power due to the higher pressure output and volume of air delivered, which increases operational costs in industrial settings. Evaluating performance efficiency involves considering duty cycles, pressure requirements, and energy consumption to determine the optimal balance between operational costs and system effectiveness.

Maintenance Requirements for Vacuum Pumps vs Air Compressors

Vacuum pumps typically require regular checks on oil levels, filter replacements, and seal inspections to ensure optimal performance and prevent contamination, while air compressors demand frequent air filter cleaning, moisture drainage, and belt tension adjustments. Your maintenance routine for a vacuum pump often involves more attention to oil quality and leak detection, contrasting with the air compressor's focus on managing compressed air moisture and ensuring proper belt alignment. Understanding these distinct maintenance needs helps extend equipment lifespan and maintain efficiency in your industrial or laboratory setup.

How to Choose: Factors in Selecting the Right Device

Selecting the right device between a vacuum pump and an air compressor depends primarily on the required application pressure and flow rate, with vacuum pumps suited for creating low-pressure environments and air compressors designed to deliver pressurized air. Consider factors such as operating pressure range, air quality requirements, energy efficiency, and maintenance needs to ensure optimal performance and cost-effectiveness. Assessing the specific industrial or laboratory task requirements, including vacuum level or pressure output, durability, and noise levels, will guide the most effective and reliable choice.

Vacuum pump vs air compressor Infographic

libmatt.com

libmatt.com