Ultrasonic cleaners use high-frequency sound waves to create microbubbles that effectively remove dirt and contaminants from delicate items without harsh chemicals. Solvent cleaners rely on chemical agents to dissolve grime but may pose health and environmental risks, making ultrasonic cleaning a safer and more efficient choice for maintaining Your valuables.

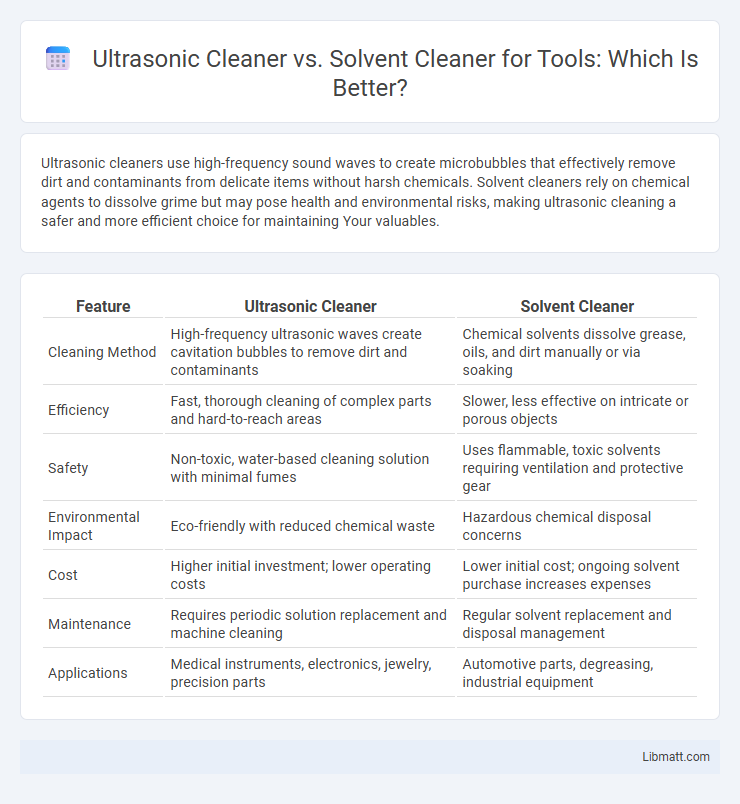

Table of Comparison

| Feature | Ultrasonic Cleaner | Solvent Cleaner |

|---|---|---|

| Cleaning Method | High-frequency ultrasonic waves create cavitation bubbles to remove dirt and contaminants | Chemical solvents dissolve grease, oils, and dirt manually or via soaking |

| Efficiency | Fast, thorough cleaning of complex parts and hard-to-reach areas | Slower, less effective on intricate or porous objects |

| Safety | Non-toxic, water-based cleaning solution with minimal fumes | Uses flammable, toxic solvents requiring ventilation and protective gear |

| Environmental Impact | Eco-friendly with reduced chemical waste | Hazardous chemical disposal concerns |

| Cost | Higher initial investment; lower operating costs | Lower initial cost; ongoing solvent purchase increases expenses |

| Maintenance | Requires periodic solution replacement and machine cleaning | Regular solvent replacement and disposal management |

| Applications | Medical instruments, electronics, jewelry, precision parts | Automotive parts, degreasing, industrial equipment |

Introduction to Cleaning Technologies

Ultrasonic cleaners use high-frequency sound waves to create cavitation bubbles that effectively remove contaminants from intricate surfaces, offering superior precision in cleaning delicate items. Solvent cleaners rely on chemical solutions to dissolve oils, greases, and other residues, making them suitable for heavy-duty applications but often requiring careful handling due to toxicity and disposal concerns. Your choice between ultrasonic and solvent cleaning technologies should consider factors like material compatibility, environmental impact, and the level of cleanliness required.

How Ultrasonic Cleaners Work

Ultrasonic cleaners use high-frequency sound waves to create microscopic cavitation bubbles in a cleaning solution, which implode to remove dirt, grease, and contaminants from surfaces with precision. This method reaches intricate parts and crevices that solvent cleaners might miss, ensuring thorough cleaning without harsh chemicals. Your items benefit from a deeper clean, reduced damage risk, and environmentally friendly maintenance compared to traditional solvent cleaning methods.

How Solvent Cleaners Operate

Solvent cleaners operate by dissolving contaminants through chemical interaction, breaking down oils, greases, and residues on surfaces. These cleaners use organic or inorganic solvents that penetrate and lift dirt, often requiring manual agitation or wiping for thorough cleaning. Unlike ultrasonic cleaners that rely on cavitation bubbles, solvent cleaners depend on the solvent's chemical properties to achieve effective contamination removal.

Key Differences Between Ultrasonic and Solvent Cleaners

Ultrasonic cleaners use high-frequency sound waves to create tiny cavitation bubbles that effectively remove dirt and contaminants from intricate surfaces without harsh chemicals. Solvent cleaners rely on chemical agents to dissolve oils, greases, and residues but can pose environmental and health risks due to toxic fumes. Your choice depends on the level of precision required, with ultrasonic cleaners offering a safer, eco-friendly option for delicate or complex items.

Efficiency and Cleaning Performance

Ultrasonic cleaners use high-frequency sound waves to generate cavitation bubbles that effectively remove contaminants from intricate surfaces, providing superior cleaning performance compared to solvent cleaners, especially for delicate or complex items. Solvent cleaners rely on chemical dissolution, which can be efficient for certain types of dirt but may leave residues and require longer drying times. Your choice depends on efficiency needs; ultrasonic cleaners offer faster, more thorough results with less environmental impact and reduced manual labor.

Safety and Environmental Impact

Ultrasonic cleaners reduce hazardous chemical exposure by using high-frequency sound waves and water-based solutions, minimizing risks to users and the environment. Solvent cleaners often contain volatile organic compounds (VOCs) and toxic chemicals that pose significant health hazards and contribute to air and water pollution. Regulatory agencies increasingly favor ultrasonic cleaning for safer, eco-friendly industrial and medical applications.

Maintenance and Operating Costs

Ultrasonic cleaners generally have higher initial costs but lower long-term maintenance and operating expenses due to minimal consumable requirements and energy-efficient operation. Solvent cleaners incur ongoing costs from purchasing and disposing of hazardous chemicals, as well as potential regulatory compliance fees. You can reduce total costs by choosing ultrasonic cleaning technology for consistent performance and lower environmental impact.

Suitable Applications for Each Method

Ultrasonic cleaners excel in removing contaminants from delicate or intricate items like jewelry, electronics, and medical instruments where precision and thoroughness are essential. Solvent cleaners are more suitable for heavy-duty degreasing tasks involving machinery parts, industrial tools, and surfaces with stubborn oil and grease residues. Your choice depends on the material's sensitivity and the nature of the contamination, ensuring optimal cleaning results without damage.

Pros and Cons: Ultrasonic Cleaner vs Solvent Cleaner

Ultrasonic cleaners offer precise, non-toxic cleaning ideal for delicate items and hard-to-reach areas, utilizing high-frequency sound waves to remove contaminants quickly; however, they can be costly and require maintenance. Solvent cleaners provide fast, effective removal of grease and heavy residues but pose health risks due to toxic fumes and flammability, demanding careful handling and disposal. Choosing between ultrasonic and solvent cleaners depends on the cleaning application's sensitivity, safety requirements, and environmental impact considerations.

Choosing the Right Cleaning Solution

Ultrasonic cleaners use high-frequency sound waves to create microscopic bubbles that efficiently remove dirt and contaminants from delicate items, making them ideal for jewelry, electronics, and precision instruments. Solvent cleaners rely on chemical solutions to dissolve grease and oils, offering strong performance for heavy-duty grime but often requiring careful handling due to toxicity and environmental concerns. Understanding the material and type of residue on Your items will help determine whether the gentle yet thorough ultrasonic method or the powerful solvent approach is the right cleaning solution.

Ultrasonic cleaner vs solvent cleaner Infographic

libmatt.com

libmatt.com