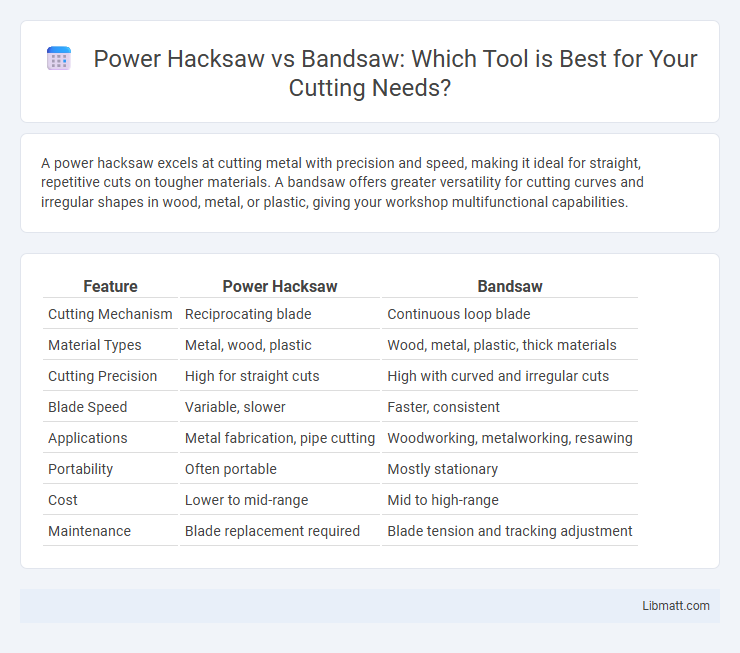

A power hacksaw excels at cutting metal with precision and speed, making it ideal for straight, repetitive cuts on tougher materials. A bandsaw offers greater versatility for cutting curves and irregular shapes in wood, metal, or plastic, giving your workshop multifunctional capabilities.

Table of Comparison

| Feature | Power Hacksaw | Bandsaw |

|---|---|---|

| Cutting Mechanism | Reciprocating blade | Continuous loop blade |

| Material Types | Metal, wood, plastic | Wood, metal, plastic, thick materials |

| Cutting Precision | High for straight cuts | High with curved and irregular cuts |

| Blade Speed | Variable, slower | Faster, consistent |

| Applications | Metal fabrication, pipe cutting | Woodworking, metalworking, resawing |

| Portability | Often portable | Mostly stationary |

| Cost | Lower to mid-range | Mid to high-range |

| Maintenance | Blade replacement required | Blade tension and tracking adjustment |

Power Hacksaw vs Bandsaw: An Overview

Power hacksaws feature a reciprocating blade ideal for precise metal cutting, offering controlled, straight cuts with minimal kerf. Bandsaws utilize continuous loop blades, providing faster, smoother cuts on various materials, including wood, metal, and plastic, with enhanced versatility. While power hacksaws excel in cutting hard metals with accuracy, bandsaws are preferred for their speed and ability to handle larger, irregular shapes.

Key Differences in Cutting Mechanism

A power hacksaw uses a reciprocating blade that moves back and forth to cut through metal, providing precise straight cuts ideal for smaller or detailed work. Bandsaws feature a continuous looped blade that moves in one direction, enabling smooth, uniform cuts and the ability to handle larger workpieces with curves and irregular shapes. The bandsaw's cutting mechanism offers greater versatility and efficiency for varied cutting tasks compared to the more limited linear motion of the power hacksaw.

Material Compatibility Comparison

Power hacksaws excel at cutting ferrous metals such as steel and iron, offering precise straight cuts ideal for heavy-duty jobs. Bandsaws provide greater versatility, effortlessly handling a wide range of materials from wood to non-ferrous metals like aluminum and brass, as well as plastics, with adjustable blade types for optimal performance. Your choice depends on the material diversity you work with and the precision required for your cuts.

Speed and Efficiency Analysis

Power hacksaws deliver rapid cutting speeds suited for straight, repetitive metal cuts, optimizing efficiency in high-volume applications by minimizing cycle time. Bandsaws, with their continuous blade motion, offer smoother, more precise cuts and greater material versatility but generally operate at slower feed rates. Your choice depends on prioritizing high-speed metal cutting efficiency or precision and adaptability across diverse materials.

Precision and Cutting Quality

Power hacksaws offer robust cutting power but often sacrifice precision due to their reciprocating blade motion, making them better suited for rough cuts on metal. Bandsaws provide superior cutting quality and precision with continuous blade movement, which results in smoother edges and more accurate cuts, especially on intricate shapes or curves. For your projects requiring detailed and clean cuts, bandsaws are generally the optimal choice for achieving higher precision and superior finish.

Maintenance and Durability

Power hacksaws require regular blade replacement and lubrication to maintain optimal cutting performance, while bandsaws demand more frequent blade tension checks and wheel alignment to prevent wear. Durability in power hacksaws is often linked to the robustness of the motor and frame, whereas bandsaws benefit from a stronger build that supports continuous heavy-duty use with less frequent breakdowns. Your choice should consider how much time you can dedicate to maintenance and the expected workload to ensure long-lasting tool performance.

Space and Portability Considerations

A power hacksaw is compact and lightweight, making it ideal for small workshops and easy to move between job sites, while a bandsaw typically requires more floor space due to its larger size and stationary design. Your choice should consider the available workspace and the need for portability, as bandsaws excel in heavy-duty cutting but are less convenient to transport. For tight areas or mobile use, a power hacksaw offers greater flexibility without sacrificing essential cutting capabilities.

Safety Features and User Ergonomics

Power hacksaws feature robust blade guards and automatic shut-off mechanisms to enhance operator safety, while their fixed cutting positions reduce the risk of accidents. Bandsaws offer adjustable blade guides and tension control, allowing for precise cuts with less physical strain, improving user ergonomics for extended use. Your choice should consider these safety and ergonomic aspects to ensure a comfortable and secure cutting experience.

Cost Implications and Value for Money

Power hacksaws typically have a lower initial cost compared to bandsaws, making them suitable for small workshops or occasional use. Bandsaws, although more expensive upfront, offer greater precision and versatility, leading to higher efficiency and reduced material waste over time. For businesses requiring frequent, heavy-duty cutting, the value for money favors bandsaws due to their durability and faster cutting speeds.

Best Applications: Which Saw to Choose?

Power hacksaws excel in cutting metal pipes, bars, and heavy-duty materials due to their precise, straight cuts and ability to handle tougher metals. Bandsaws offer versatility for curved cuts and are ideal for wood, plastic, and metal cutting with smoother finishes and less material waste. Your choice depends on whether you need precision straight cuts for metal fabrication (power hacksaw) or versatile, intricate cuts across various materials (bandsaw).

Power hacksaw vs bandsaw Infographic

libmatt.com

libmatt.com