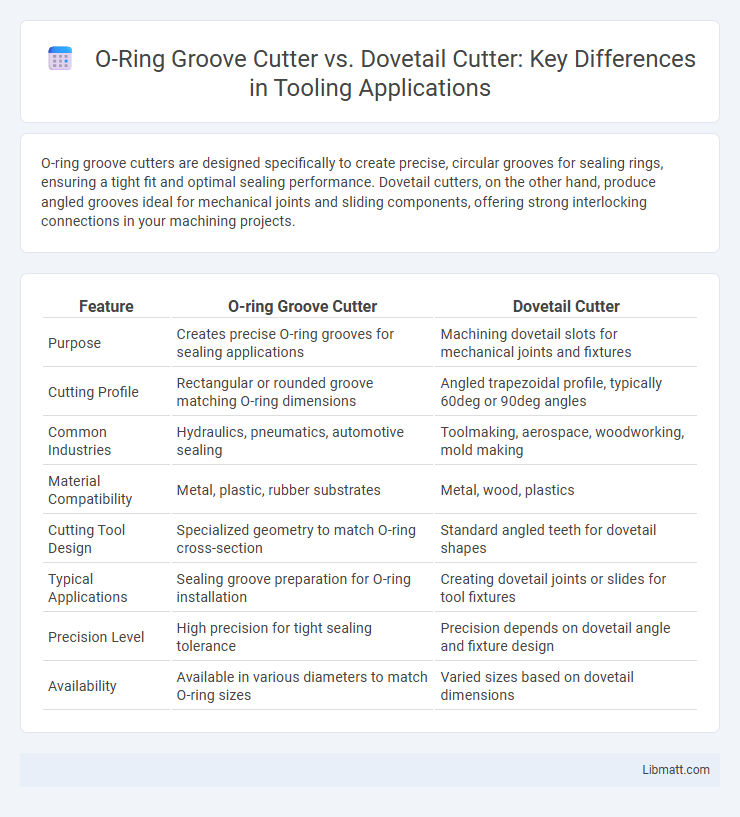

O-ring groove cutters are designed specifically to create precise, circular grooves for sealing rings, ensuring a tight fit and optimal sealing performance. Dovetail cutters, on the other hand, produce angled grooves ideal for mechanical joints and sliding components, offering strong interlocking connections in your machining projects.

Table of Comparison

| Feature | O-ring Groove Cutter | Dovetail Cutter |

|---|---|---|

| Purpose | Creates precise O-ring grooves for sealing applications | Machining dovetail slots for mechanical joints and fixtures |

| Cutting Profile | Rectangular or rounded groove matching O-ring dimensions | Angled trapezoidal profile, typically 60deg or 90deg angles |

| Common Industries | Hydraulics, pneumatics, automotive sealing | Toolmaking, aerospace, woodworking, mold making |

| Material Compatibility | Metal, plastic, rubber substrates | Metal, wood, plastics |

| Cutting Tool Design | Specialized geometry to match O-ring cross-section | Standard angled teeth for dovetail shapes |

| Typical Applications | Sealing groove preparation for O-ring installation | Creating dovetail joints or slides for tool fixtures |

| Precision Level | High precision for tight sealing tolerance | Precision depends on dovetail angle and fixture design |

| Availability | Available in various diameters to match O-ring sizes | Varied sizes based on dovetail dimensions |

Introduction to O-Ring Groove Cutter and Dovetail Cutter

O-ring groove cutters are specifically designed to create precise and smooth grooves for O-ring installation, ensuring a perfect seal and preventing leaks in mechanical assemblies. Dovetail cutters, on the other hand, are used to machine dovetail joints with angled sides for strong interlocking parts, commonly utilized in woodworking and metalworking. Both cutters are essential in manufacturing processes, with the O-ring groove cutter optimized for sealing applications and the dovetail cutter tailored for structural stability.

Key Differences Between O-Ring Groove Cutters and Dovetail Cutters

O-ring groove cutters are specifically designed to create precise circular grooves for sealing applications, ensuring optimal fit and preventing leaks, while dovetail cutters produce angled grooves ideal for dovetail joints in woodworking or metalworking, offering strong mechanical interlocks. The key differences lie in their cutting geometry, with O-ring cutters featuring a specialized profile for sealing accuracy and dovetail cutters possessing a trapezoidal shape for structural support. Selecting the right cutter depends on whether your project demands airtight sealing or robust joint strength.

Design and Functionality: O-Ring Groove Cutter

O-ring groove cutters are specifically designed to create precise, uniform grooves that securely hold O-rings in place, ensuring effective sealing in mechanical assemblies. Their geometry features a rounded profile that matches the O-ring cross-section, providing consistent compression and minimizing leakage risks. This specialized design enhances the cutter's functionality by enabling accurate, clean cuts essential for high-performance sealing applications.

Design and Functionality: Dovetail Cutter

A dovetail cutter features a unique angled tip designed to create precise, undercut profiles essential for dovetail joints and slots, providing superior mechanical interlocking. Its design allows for angled cutting edges that efficiently remove material while maintaining accuracy and surface finish in machining operations. This cutter type is especially effective for creating grooves that require high strength and stability in assembled components.

Applications of O-Ring Groove Cutters

O-ring groove cutters are specifically designed for machining precise and consistent grooves to securely hold O-rings, ensuring reliable sealing in hydraulic cylinders, pneumatic systems, and various mechanical assemblies. These cutters provide superior edge finish and dimensional accuracy, reducing leakage risks and enhancing the durability of seals in automotive, aerospace, and industrial equipment. Choosing the right O-ring groove cutter for Your application guarantees optimal fit and performance, crucial for maintaining system integrity and preventing costly downtime.

Applications of Dovetail Cutters

Dovetail cutters are specialized tools primarily used for creating angled grooves that allow mechanical parts to interlock securely, often in woodworking and metalworking projects such as drawer slides, engineering components, and assembly fixtures. Unlike O-ring groove cutters designed for sealing applications, dovetail cutters enable precise shaping of joints that require strong, load-bearing connections or guide systems. Your choice of a dovetail cutter enhances the reliability and alignment of components in complex assemblies where precise dovetail grooves are essential.

Material Compatibility and Performance

O-ring groove cutters excel in cutting soft to medium materials like rubber and plastics due to their precise geometry tailored for sealing applications, ensuring accurate groove dimensions and optimal seal performance. Dovetail cutters, designed with an angled cutting edge, perform well on metals and harder materials such as aluminum and steel, facilitating undercut grooves with excellent surface finish and durability. Selecting between these cutters depends on material hardness and the required groove profile for achieving reliable sealing or mechanical fit.

Precision and Efficiency Comparison

O-ring groove cutters provide superior precision by creating perfectly rounded grooves that ensure optimal sealing performance, essential for high-pressure applications. Dovetail cutters excel in efficiency by quickly producing angled grooves with strong mechanical interlocking for components requiring high stability. Choosing the right tool depends on your need for either precise sealing geometry or rapid, strong joint fabrication.

Cost-Effectiveness and Tool Lifespan

O-ring groove cutters typically offer greater cost-effectiveness due to their specialized design that reduces machining time and material waste, extending tool lifespan by minimizing wear during groove cutting. Dovetail cutters, while versatile for multiple machining tasks, often experience faster tool wear when used for O-ring grooves, resulting in higher replacement costs over time. Selecting an O-ring groove cutter optimizes operational efficiency and tool durability in applications requiring precise groove shapes, ultimately reducing overall tooling expenses.

Choosing the Right Cutter for Your Project

Selecting the right cutter depends on your project's specific requirements for sealing and joint type; an O-ring groove cutter is ideal for precise circular grooves that ensure a tight seal, while a dovetail cutter excels in creating angular undercuts for mechanical joints and fastening. Your choice will impact the quality and durability of the assembly, with groove cutters providing uniform O-ring placement and dovetail cutters offering robust interlocking features. Consider the material, tolerance, and design complexity to optimize performance and tool longevity.

O-ring groove cutter vs dovetail cutter Infographic

libmatt.com

libmatt.com