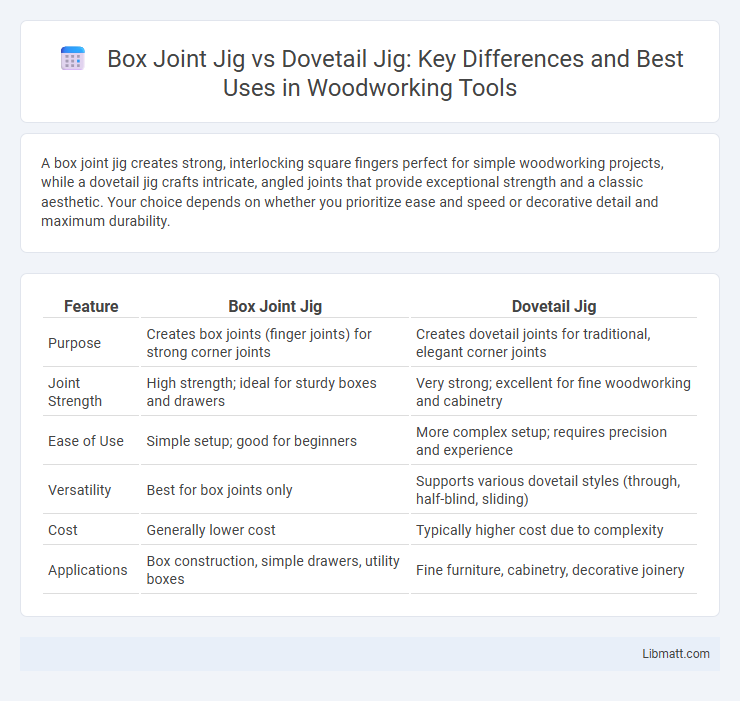

A box joint jig creates strong, interlocking square fingers perfect for simple woodworking projects, while a dovetail jig crafts intricate, angled joints that provide exceptional strength and a classic aesthetic. Your choice depends on whether you prioritize ease and speed or decorative detail and maximum durability.

Table of Comparison

| Feature | Box Joint Jig | Dovetail Jig |

|---|---|---|

| Purpose | Creates box joints (finger joints) for strong corner joints | Creates dovetail joints for traditional, elegant corner joints |

| Joint Strength | High strength; ideal for sturdy boxes and drawers | Very strong; excellent for fine woodworking and cabinetry |

| Ease of Use | Simple setup; good for beginners | More complex setup; requires precision and experience |

| Versatility | Best for box joints only | Supports various dovetail styles (through, half-blind, sliding) |

| Cost | Generally lower cost | Typically higher cost due to complexity |

| Applications | Box construction, simple drawers, utility boxes | Fine furniture, cabinetry, decorative joinery |

Introduction to Box Joint and Dovetail Jigs

Box joint jigs and dovetail jigs are essential woodworking tools designed to create strong, interlocking joints for box and drawer construction. Box joint jigs produce simple, square-cut fingers that offer durability and ease of assembly, making them ideal for beginner to intermediate woodworkers. Dovetail jigs create angled, wedge-shaped joints known for their superior strength and aesthetic appeal, often preferred in fine cabinet and furniture making.

Key Differences Between Box Joint and Dovetail Jigs

Box joint jigs create interlocking rectangular fingers ideal for strong, straightforward corner joints, while dovetail jigs produce angled, fan-shaped tails and pins that offer superior tensile strength and aesthetic appeal. Box joints are simpler to set up and faster to cut, making them suitable for beginners and quicker projects, whereas dovetail jigs require more precision and time but result in highly durable and visually intricate joints. Your choice depends on whether you prioritize ease and speed with box joints or strength and craftsmanship with dovetail joints.

Design and Construction of Box Joint Jigs

Box joint jigs are specifically designed with adjustable fences and precise stop blocks to ensure uniform finger spacing for strong interlocking joints. These jigs often feature robust aluminum or steel construction combined with hardwood components to maintain rigidity and accuracy during repetitive cuts. Your choice of a box joint jig impacts the ease of achieving perfectly aligned box joints, especially when compared to dovetail jigs that require more intricate layout and cutting precision.

Design and Construction of Dovetail Jigs

Dovetail jigs feature precision clamps and templates designed for creating interlocking joints with angled pins and tails, ensuring strong and attractive corner assemblies. These jigs are often constructed from durable metal or high-grade plastic to maintain accuracy and withstand wear during repeated use. Your woodworking projects benefit from the consistent alignment and fine detail achievable with a well-built dovetail jig, surpassing simpler box joint jigs in producing elegant, tight-fitting joints.

Strength and Durability Comparison

Box joint jigs create interlocking fingers that offer superior strength and durability due to their increased gluing surface area, making them ideal for heavy-duty woodworking projects. Dovetail jigs produce angled joints known for elegant aesthetics and strong mechanical resistance, especially in drawer construction, but typically have less glue surface compared to box joints. Your choice depends on whether you prioritize maximum joint strength or decorative appeal, with box joints generally outperforming dovetails in load-bearing applications.

Ease of Use and Setup

Box joint jigs offer straightforward setup with simple alignment and fewer adjustments, making them ideal for beginners or quick projects. Dovetail jigs require more precise calibration and multiple setup steps to achieve tight, interlocking joints, which can be time-consuming for novices. Your choice depends on whether ease of use or intricate joint detail is your priority.

Applications and Ideal Use Cases

Box joint jigs excel in creating strong, simple interlocking joints ideal for boxes, drawers, and cabinetry where durability and straightforward assembly are priorities. Dovetail jigs produce intricate, aesthetically pleasing joints perfect for fine woodworking projects like decorative drawers and high-end furniture requiring enhanced strength and visual appeal. Choosing between the two depends on the project's structural requirements and design complexity.

Material Compatibility and Versatility

Box joint jigs excel in compatibility with a wide range of hardwoods, softwoods, and plywood, offering versatility for both thick and thin materials. Dovetail jigs are specifically designed for precise interlocking joints in solid wood, particularly hardwoods, and tend to be less adaptable to plywood or MDF. Choosing between the two depends on the desired joint style and the types of wood materials typically used in your woodworking projects.

Cost and Value for Woodworkers

Box joint jigs typically offer a more affordable entry point for woodworkers compared to dovetail jigs, making them ideal for budget-conscious hobbyists seeking strong, functional joints. Dovetail jigs, while more expensive, deliver superior aesthetic appeal and precision, providing greater value for professionals focused on fine woodworking and detailed craftsmanship. Your choice depends on balancing initial cost with long-term value, where box joint jigs prioritize budget and dovetail jigs emphasize quality and visual impact.

Choosing the Right Jig for Your Project

Selecting between a box joint jig and a dovetail jig depends on the project's structural and aesthetic requirements; box joint jigs excel in creating strong, interlocking finger joints ideal for drawers and boxes, while dovetail jigs produce intricate, angled joints favored for fine woodworking and cabinetry. The choice hinges on the desired joint strength, visual appeal, and complexity, with box joints offering simplicity and durability, and dovetails providing superior resistance to pulling forces and a classic appearance. Evaluating the wood type, tool compatibility, and skill level will ensure the chosen jig maximizes both functionality and craftsmanship in the final piece.

Box joint jig vs dovetail jig Infographic

libmatt.com

libmatt.com