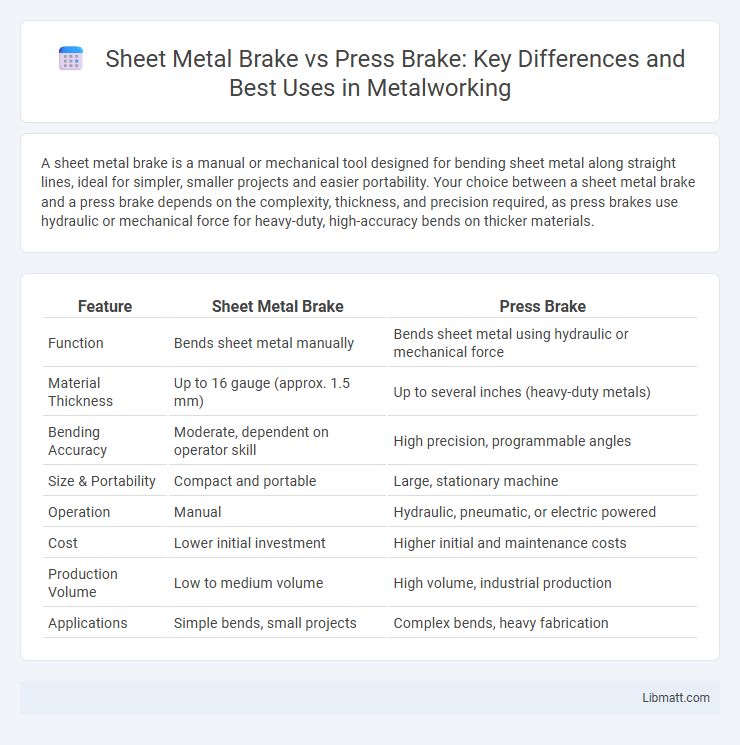

A sheet metal brake is a manual or mechanical tool designed for bending sheet metal along straight lines, ideal for simpler, smaller projects and easier portability. Your choice between a sheet metal brake and a press brake depends on the complexity, thickness, and precision required, as press brakes use hydraulic or mechanical force for heavy-duty, high-accuracy bends on thicker materials.

Table of Comparison

| Feature | Sheet Metal Brake | Press Brake |

|---|---|---|

| Function | Bends sheet metal manually | Bends sheet metal using hydraulic or mechanical force |

| Material Thickness | Up to 16 gauge (approx. 1.5 mm) | Up to several inches (heavy-duty metals) |

| Bending Accuracy | Moderate, dependent on operator skill | High precision, programmable angles |

| Size & Portability | Compact and portable | Large, stationary machine |

| Operation | Manual | Hydraulic, pneumatic, or electric powered |

| Cost | Lower initial investment | Higher initial and maintenance costs |

| Production Volume | Low to medium volume | High volume, industrial production |

| Applications | Simple bends, small projects | Complex bends, heavy fabrication |

Introduction to Sheet Metal Brakes and Press Brakes

Sheet metal brakes and press brakes are essential tools in metal fabrication used for bending sheet metal accurately. A sheet metal brake typically features a clamping bar and a bending leaf, allowing precise manual or hydraulic bends for lighter gauge metals. Press brakes utilize a punch and die setup with hydraulic, mechanical, or servo-electric power to achieve complex bends and high tonnage in thicker metal sheets.

Understanding Sheet Metal Brake: Definition and Function

A sheet metal brake is a manual or hydraulic tool designed to bend sheet metal into precise angles by clamping the metal and lifting a hinged bending leaf. It is primarily used for simple, straight bends and small-scale fabrication tasks, allowing operators to create creases, hems, and flanges efficiently. Unlike a press brake, which uses a punch and die system for complex and heavy-duty bending, a sheet metal brake offers more straightforward bending functions suitable for thinner gauges and less intricate shapes.

What Is a Press Brake? Core Features Explained

A press brake is a machine tool used for bending sheet metal with high precision by applying force through a punch and die setup, enabling complex and accurate bends. Core features include a robust frame, hydraulic or mechanical power source, adjustable back gauge for positioning, and a control system for programmable bending angles and sequences. Unlike a sheet metal brake, a press brake offers greater versatility and automation, making it essential for industrial-scale metal fabrication.

Key Differences Between Sheet Metal Brake and Press Brake

Sheet metal brakes are manual or hydraulic tools designed for bending sheet metal at simple, straight angles, making them ideal for small to medium-scale projects requiring precise, clean folds. Press brakes utilize a punch and die system with hydraulic or CNC control to perform complex bends, multiple angles, and varying radii on thicker metal sheets with higher accuracy and automation. Key differences include operational complexity, bending capacity, precision, and suitability for production scale, with press brakes excelling in versatility and heavy-duty applications compared to the straightforward function of sheet metal brakes.

Material Thickness and Bending Capabilities Comparison

Sheet metal brakes typically handle thinner materials, often up to 16 gauge steel (about 0.06 inches), making them ideal for light to medium gauge sheet metals. Press brakes offer superior bending capabilities, efficiently working with thicker materials ranging from 10 gauge to over 1 inch, depending on machine tonnage. The press brake's ability to apply high force enables precise bends on heavy-duty metals, while sheet metal brakes provide quicker, simpler bends for less demanding thicknesses.

Precision and Accuracy: Which Brake Performs Better?

Press brakes typically offer superior precision and accuracy compared to sheet metal brakes due to their advanced hydraulic or mechanical systems that enable consistent and repeatable bends. While sheet metal brakes are suitable for simpler, less precise bends, press brakes ensure tighter tolerances for complex or high-volume fabrication tasks. If your project demands exact bend angles and uniformity, a press brake is generally the better-performing choice.

Typical Applications: When to Use Each Brake Type

Sheet metal brakes are ideal for simple bends and straight folds in lighter gauge materials, making them suitable for tasks like ductwork, roofing, and basic fabrication projects. Press brakes excel in complex bends, precise angles, and heavier gauge metals, commonly used in automotive panels, industrial machinery, and structural components. Your choice depends on the material thickness and complexity of the bend, with sheet metal brakes better for straightforward jobs and press brakes preferred for detailed or heavy-duty applications.

Cost Considerations and Investment Analysis

Sheet metal brakes generally require a lower initial investment, making them ideal for smaller workshops or hobbyists with budget constraints, while press brakes involve higher upfront costs due to advanced technology and hydraulic systems. Operating expenses vary as press brakes demand skilled operators and regular maintenance, yet they offer increased precision, faster production speeds, and scalability that can justify the investment in high-volume or industrial applications. Cost analysis should weigh the volume of production, material types, and desired bend accuracy to determine the most cost-effective solution between traditional sheet metal brakes and sophisticated press brakes.

Maintenance, Durability, and Lifespan Factors

Sheet metal brakes require regular lubrication and alignment to maintain precision, while press brakes demand routine hydraulic system checks and software updates for optimal performance. Durability in sheet metal brakes depends heavily on manual handling and build quality, whereas press brakes benefit from robust construction and advanced control systems that enhance operational consistency. Your choice between the two should consider maintenance schedules and expected lifespan, as sheet metal brakes typically have lower upfront costs but shorter lifespan compared to the more durable and versatile press brakes.

Which Brake Is Right for Your Shop? Decision Guide

Choosing between a sheet metal brake and a press brake depends on your shop's production volume, material thickness, and bending precision requirements. Sheet metal brakes are ideal for small-scale projects and simple bends, offering affordability and ease of use, while press brakes excel in high-volume operations with thicker materials, providing precise, complex bends through hydraulic or CNC controls. Assess your workflow needs, space constraints, and budget to determine whether manual or automated bending technology best aligns with your fabrication goals.

Sheet metal brake vs press brake Infographic

libmatt.com

libmatt.com