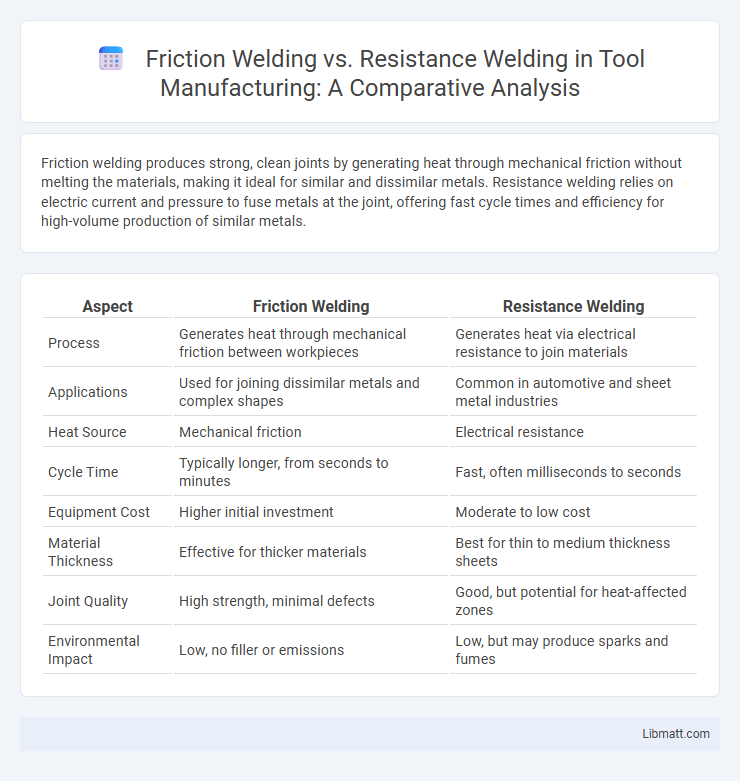

Friction welding produces strong, clean joints by generating heat through mechanical friction without melting the materials, making it ideal for similar and dissimilar metals. Resistance welding relies on electric current and pressure to fuse metals at the joint, offering fast cycle times and efficiency for high-volume production of similar metals.

Table of Comparison

| Aspect | Friction Welding | Resistance Welding |

|---|---|---|

| Process | Generates heat through mechanical friction between workpieces | Generates heat via electrical resistance to join materials |

| Applications | Used for joining dissimilar metals and complex shapes | Common in automotive and sheet metal industries |

| Heat Source | Mechanical friction | Electrical resistance |

| Cycle Time | Typically longer, from seconds to minutes | Fast, often milliseconds to seconds |

| Equipment Cost | Higher initial investment | Moderate to low cost |

| Material Thickness | Effective for thicker materials | Best for thin to medium thickness sheets |

| Joint Quality | High strength, minimal defects | Good, but potential for heat-affected zones |

| Environmental Impact | Low, no filler or emissions | Low, but may produce sparks and fumes |

Introduction to Friction Welding and Resistance Welding

Friction welding is a solid-state joining process that generates heat through mechanical friction between workpieces, producing strong, defect-free joints without melting the materials. Resistance welding relies on electrical resistance to generate heat at the interface of the metals, causing localized melting and fusion to form the weld. Both methods are widely used in automotive and aerospace industries for their efficiency and structural integrity in joining dissimilar metals.

Definition and Basic Principles

Friction welding joins materials by generating heat through mechanical friction between workpieces under pressure, causing plastic deformation and bonding without melting. Resistance welding uses electrical resistance to produce heat at the interface of the components, where pressure is applied to form the weld as the metal reaches a molten state. Your choice depends on the materials, joint design, and desired weld properties, with friction welding excelling in solid-state bonding and resistance welding suited for high-speed, automated processes.

Key Differences Between Friction and Resistance Welding

Friction welding uses mechanical heat generated by rubbing two surfaces together under pressure, creating a solid-state bond without melting the base materials, whereas resistance welding relies on electrical resistance to produce heat that melts and fuses metals at the joint. Friction welding typically offers superior joint strength and is ideal for dissimilar metals, while resistance welding excels in high-speed, automated production environments, commonly used in sheet metal fabrication. The absence of filler materials in friction welding reduces contamination risks, contrasting with resistance welding's dependence on precise electrical parameters to ensure consistent weld quality.

Advantages of Friction Welding

Friction welding offers distinct advantages such as producing high-strength joints without melting the base materials, resulting in minimal distortion and superior mechanical properties. Its ability to join dissimilar metals and complex shapes with excellent metallurgical integrity makes it ideal for aerospace and automotive applications. You benefit from faster cycle times and environmentally friendly processes due to the absence of additional filler materials or flux.

Benefits of Resistance Welding

Resistance welding offers rapid processing speeds and consistent weld quality, making it ideal for high-volume manufacturing. Its energy efficiency and minimal filler materials reduce overall production costs while ensuring strong, reliable joints. You benefit from precise heat control, allowing for reduced thermal distortion and improved structural integrity in metal assemblies.

Typical Applications in Industry

Friction welding is commonly utilized for joining dissimilar metals in aerospace, automotive, and heavy machinery manufacturing, offering high-strength joints without melting the base materials. Resistance welding is frequently applied in mass production industries like automotive assembly and electronics, where fast, repeatable spot or seam welds are essential. Your choice between these methods depends on factors such as material types, production volume, and joint design requirements.

Material Compatibility and Suitability

Friction welding excels in joining dissimilar metals such as aluminum to steel, titanium to copper, or stainless steel to carbon steel due to its solid-state process that prevents melting and reduces intermetallic formation. Resistance welding, including spot and seam welding, is best suited for compatible materials like similar steels and thin sheet metals because it relies on electrical resistance to generate heat at the interface. Understanding your material compatibility ensures selecting the welding method that maximizes joint strength, minimizes defects, and optimizes production efficiency.

Equipment and Process Requirements

Friction welding requires specialized equipment including a rotating spindle and controlled axial pressure to generate heat through friction, enabling solid-state joining without melting the materials. Resistance welding relies on electrodes that apply pressure and pass an electric current through the materials, producing heat from the electrical resistance to form the weld. The key process difference is that friction welding necessitates mechanical movement and precise control of rotational speed and pressure, whereas resistance welding requires accurate control of current, electrode force, and timing for consistent weld quality.

Cost Comparison and Efficiency

Friction welding typically incurs higher initial equipment costs but offers superior energy efficiency and faster production cycles compared to resistance welding, which benefits from lower startup expenses and simpler machinery. The overall operational cost of friction welding decreases in high-volume manufacturing due to reduced material waste and minimal post-processing. Resistance welding, however, remains cost-effective for smaller batch sizes with less complex joint designs, balancing equipment investment against throughput requirements.

Choosing the Right Welding Method

Choosing the right welding method depends on your project's material types, thickness, and production speed requirements. Friction welding offers superior joint strength and minimal defects by generating heat through mechanical friction without melting, making it ideal for dissimilar metals and aerospace applications. Resistance welding, using electric current to create heat at the interface, suits high-volume manufacturing of thin sheet metals, providing cost-efficiency and fast cycle times.

Friction welding vs resistance welding Infographic

libmatt.com

libmatt.com