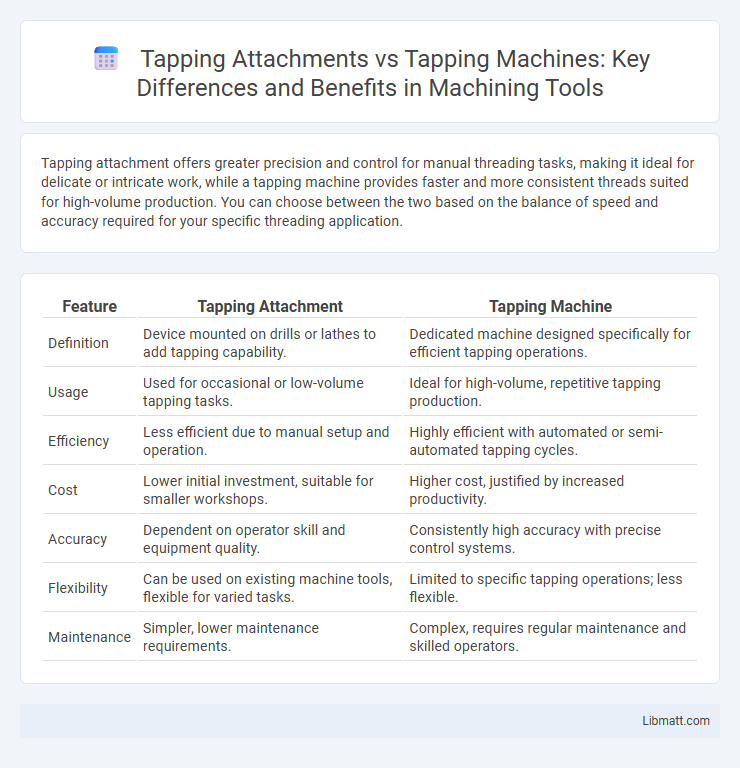

Tapping attachment offers greater precision and control for manual threading tasks, making it ideal for delicate or intricate work, while a tapping machine provides faster and more consistent threads suited for high-volume production. You can choose between the two based on the balance of speed and accuracy required for your specific threading application.

Table of Comparison

| Feature | Tapping Attachment | Tapping Machine |

|---|---|---|

| Definition | Device mounted on drills or lathes to add tapping capability. | Dedicated machine designed specifically for efficient tapping operations. |

| Usage | Used for occasional or low-volume tapping tasks. | Ideal for high-volume, repetitive tapping production. |

| Efficiency | Less efficient due to manual setup and operation. | Highly efficient with automated or semi-automated tapping cycles. |

| Cost | Lower initial investment, suitable for smaller workshops. | Higher cost, justified by increased productivity. |

| Accuracy | Dependent on operator skill and equipment quality. | Consistently high accuracy with precise control systems. |

| Flexibility | Can be used on existing machine tools, flexible for varied tasks. | Limited to specific tapping operations; less flexible. |

| Maintenance | Simpler, lower maintenance requirements. | Complex, requires regular maintenance and skilled operators. |

Introduction to Tapping Attachments and Tapping Machines

Tapping attachments are precision tools designed to convert standard drilling machines into tapping machines, enabling efficient internal threading with consistent alignment and torque control. Tapping machines, by contrast, are dedicated equipment built specifically for high-volume threading tasks, offering automated feed mechanisms and superior accuracy for industrial applications. Your choice between a tapping attachment and a tapping machine depends on production volume, required precision, and budget constraints.

How Tapping Attachments Work

Tapping attachments operate by converting the rotary motion of the drilling machine into precise, controlled tapping motion, enabling efficient thread cutting in various materials. They feature adjustable feed mechanisms that synchronize spindle rotation with the linear feed, ensuring consistent thread pitch and preventing tap breakage. These attachments are ideal for enhancing productivity and accuracy compared to manual tapping or dedicated tapping machines.

How Tapping Machines Operate

Tapping machines operate by precisely rotating a cutting tool called a tap into a pre-drilled hole to create internal threads, ensuring consistent thread quality and speed. Unlike manual tapping attachments, these machines utilize automated feed mechanisms and controlled torque to prevent tap breakage and enhance efficiency in high-volume production. Your choice of a tapping machine depends on the required thread size, material hardness, and production scale to optimize threading operations.

Key Differences Between Tapping Attachments and Tapping Machines

Tapping attachments are auxiliary tools mounted on existing drilling machines or milling machines, enabling manual or semi-automatic tapping with enhanced flexibility for various hole sizes and thread types. In contrast, tapping machines are dedicated units designed specifically for high-volume, fully automated tapping operations with superior precision and repeatability. Key differences include the level of automation, installation requirements, and throughput capacity, where tapping attachments offer versatility and lower cost, while tapping machines provide efficiency and consistency for mass production.

Advantages of Using Tapping Attachments

Tapping attachments offer precise control and increased efficiency by allowing you to use your existing drill press or milling machine for threading tasks, reducing the need for specialized equipment. They enhance productivity through faster setup times and improved alignment, minimizing errors and tool wear. Choosing a tapping attachment provides a cost-effective, versatile solution for consistent and accurate internal threading.

Benefits of Choosing Tapping Machines

Tapping machines offer precision and consistency, significantly reducing the risk of thread damage compared to manual tapping attachments. These machines enhance productivity by maintaining uniform speed and pressure, which improves thread quality and minimizes operator fatigue. Your manufacturing process benefits from faster cycle times, increased accuracy, and lower defect rates when using tapping machines.

Application Scenarios: Attachment vs Machine

Tapping attachments are ideal for CNC machines and drilling centers where space and tool change efficiency are crucial, enabling precision threading in small to medium batch production. Tapping machines excel in high-volume manufacturing environments, providing faster cycle times and robust threading capabilities for larger workpieces and repetitive tasks. The choice depends on production scale and part complexity, with attachments suited for flexibility and machines for dedicated, high-output tapping operations.

Cost Comparison and Investment Considerations

Tapping attachments typically offer a lower upfront cost compared to dedicated tapping machines, making them a budget-friendly option for smaller-scale or occasional tapping tasks. However, tapping machines provide greater precision, speed, and durability, resulting in higher long-term productivity and potentially lower operational costs over time. When evaluating investment considerations, you should weigh initial expenditures against your tapping volume, required accuracy, and maintenance expenses to determine the most cost-effective solution for your specific workflow needs.

Precision and Efficiency Analysis

Tapping attachments provide enhanced precision by directly aligning with the machine spindle, ensuring accurate thread cutting with minimal deviation. Tapping machines, designed for high-volume production, excel in efficiency by automating the entire threading process, reducing cycle times significantly. Your choice depends on whether precision or throughput is the priority in your manufacturing workflow.

Selecting the Right Solution for Your Tapping Needs

Choosing between a tapping attachment and a tapping machine depends on production volume and precision requirements; tapping attachments are suitable for versatile, low to medium volume tasks, offering flexibility and cost-effectiveness. Tapping machines excel in high-volume, repetitive operations where consistent thread quality and speed are critical, enhancing productivity in manufacturing environments. Evaluating factors such as thread size, material hardness, and workspace constraints ensures the optimal selection tailored to your tapping needs.

Tapping attachment vs tapping machine Infographic

libmatt.com

libmatt.com