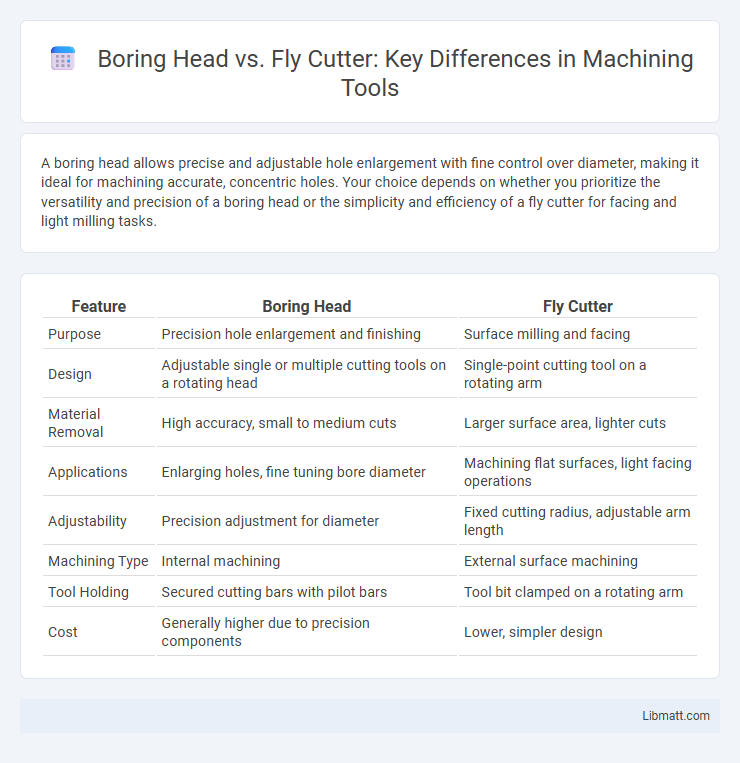

A boring head allows precise and adjustable hole enlargement with fine control over diameter, making it ideal for machining accurate, concentric holes. Your choice depends on whether you prioritize the versatility and precision of a boring head or the simplicity and efficiency of a fly cutter for facing and light milling tasks.

Table of Comparison

| Feature | Boring Head | Fly Cutter |

|---|---|---|

| Purpose | Precision hole enlargement and finishing | Surface milling and facing |

| Design | Adjustable single or multiple cutting tools on a rotating head | Single-point cutting tool on a rotating arm |

| Material Removal | High accuracy, small to medium cuts | Larger surface area, lighter cuts |

| Applications | Enlarging holes, fine tuning bore diameter | Machining flat surfaces, light facing operations |

| Adjustability | Precision adjustment for diameter | Fixed cutting radius, adjustable arm length |

| Machining Type | Internal machining | External surface machining |

| Tool Holding | Secured cutting bars with pilot bars | Tool bit clamped on a rotating arm |

| Cost | Generally higher due to precision components | Lower, simpler design |

Introduction to Boring Heads and Fly Cutters

Boring heads and fly cutters are essential tools in machining for enlarging or refining holes and creating smooth surfaces. Boring heads provide precise hole diameter adjustments through fine-tuning capabilities, making them ideal for accurate internal machining. Fly cutters, equipped with a single-point cutting tool, excel at producing flat, smooth surfaces on large workpieces with their wide cutting path.

Key Differences Between Boring Heads and Fly Cutters

Boring heads offer precise adjustable diameter control for enlarging existing holes, making them ideal for fine-tuning and achieving exact dimensions in machining. Fly cutters use a single-position cutting tool on a rotating arm, suitable for creating large, flat surfaces but less precise for hole sizing. Your choice depends on whether you prioritize accuracy in hole enlargement or efficient surface finishing.

Applications of Boring Heads in Machining

Boring heads are essential in precision machining for enlarging and finishing pre-drilled holes with high accuracy, commonly used in engine cylinder work and aerospace component manufacturing. They excel in achieving tight tolerances and smooth surface finishes, making them ideal for internal diameter adjustments and creating precise holes in metal parts. Compared to fly cutters, boring heads offer greater control over hole size and alignment, enhancing machining efficiency in complex and critical engineering applications.

Typical Uses for Fly Cutters

Fly cutters are primarily used for creating flat surfaces on large workpieces such as engine heads, machine beds, or precision tooling bases. They are ideal for face milling operations that require a high-quality finish and precise flatness over broad areas. Their versatility and ability to handle varying diameters make them especially useful in metalworking and machining tasks where uniform surface plane is critical.

Precision and Accuracy: Boring Head vs Fly Cutter

A boring head offers superior precision and accuracy compared to a fly cutter, as it allows for fine adjustment of the cutting diameter and better control over tolerances. Fly cutters excel in producing smooth surface finishes but lack the exact dimensional control found in boring heads, making them less suitable for tasks requiring tight precision. Choosing a boring head ensures your machining operations achieve exact specifications and consistent results, especially for critical hole enlargements and fine-tuning.

Surface Finish Comparison

Boring heads typically produce a finer surface finish compared to fly cutters due to their precise cutting geometry and adjustable tool positioning. Fly cutters, while capable of removing large amounts of material quickly, often leave a rougher surface finish because the single-point cutting tool generates a scalloped pattern on the workpiece. For applications requiring superior surface smoothness and dimensional accuracy, boring heads are generally preferred over fly cutters.

Tool Setup and Ease of Use

Boring heads require precise alignment and installation on milling machines, often demanding calibration for accurate hole sizing, which can be time-consuming for beginners. Fly cutters offer simpler setup with a single-point cutting tool, making them more user-friendly for creating larger surface cuts or shallow bores. The ease of adjusting a fly cutter's cutting diameter by repositioning the tool holder appeals to machinists prioritizing quick changes and straightforward operation.

Cost and Tool Maintenance

Boring heads generally have a higher upfront cost due to their precision components and versatility in adjusting hole diameters, while fly cutters are more budget-friendly with simpler construction. Maintenance for boring heads requires careful calibration and regular lubrication to maintain accuracy, whereas fly cutters demand minimal upkeep but may need frequent blade sharpening or replacement. Choosing the right tool can save you money long-term by balancing initial investment against ongoing maintenance expenses.

Choosing the Right Tool for Your Project

Choosing between a boring head and a fly cutter depends on the precision and surface finish your project demands. A boring head offers fine-tuned hole enlargement with high accuracy, ideal for tasks requiring tight tolerances. Your selection should consider the material, machining needs, and desired hole size to ensure optimal results.

Conclusion: Boring Head or Fly Cutter?

Choosing between a boring head and a fly cutter depends on machining precision and surface finish requirements; boring heads deliver superior accuracy and control for enlarging holes with tight tolerances. Fly cutters offer efficient material removal and smooth finishes on flat surfaces but lack the fine adjustment capabilities of boring heads. For applications demanding high precision in hole dimensions, a boring head is the optimal tool, while fly cutters suit broader, less precise facing tasks.

Boring head vs fly cutter Infographic

libmatt.com

libmatt.com