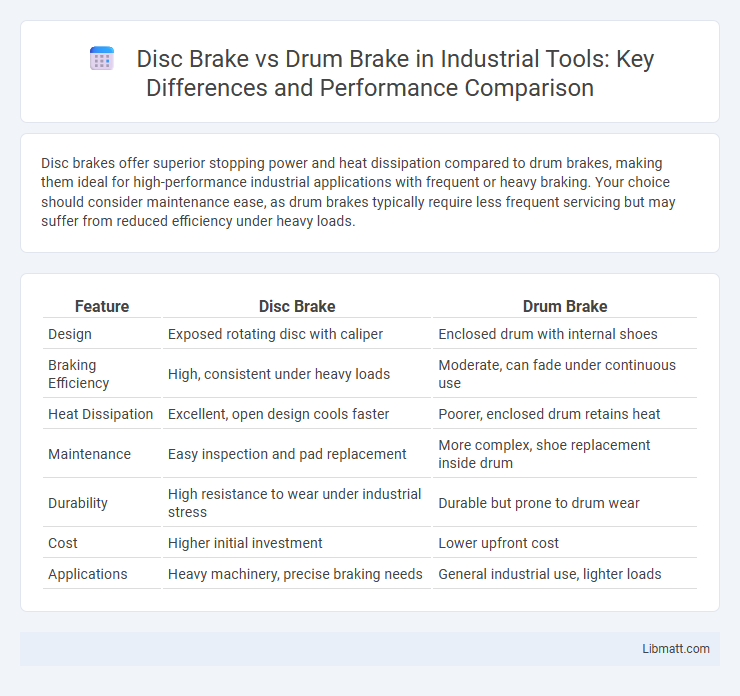

Disc brakes offer superior stopping power and heat dissipation compared to drum brakes, making them ideal for high-performance industrial applications with frequent or heavy braking. Your choice should consider maintenance ease, as drum brakes typically require less frequent servicing but may suffer from reduced efficiency under heavy loads.

Table of Comparison

| Feature | Disc Brake | Drum Brake |

|---|---|---|

| Design | Exposed rotating disc with caliper | Enclosed drum with internal shoes |

| Braking Efficiency | High, consistent under heavy loads | Moderate, can fade under continuous use |

| Heat Dissipation | Excellent, open design cools faster | Poorer, enclosed drum retains heat |

| Maintenance | Easy inspection and pad replacement | More complex, shoe replacement inside drum |

| Durability | High resistance to wear under industrial stress | Durable but prone to drum wear |

| Cost | Higher initial investment | Lower upfront cost |

| Applications | Heavy machinery, precise braking needs | General industrial use, lighter loads |

Introduction to Industrial Braking Systems

Industrial braking systems rely on disc brakes and drum brakes to ensure machinery safety and operational control. Disc brakes offer superior heat dissipation and consistent performance in high-speed, heavy-load environments, making them ideal for modern industrial applications. Your choice between disc and drum brakes should consider factors like maintenance ease, braking force, and environmental conditions to optimize system reliability.

Overview: Disc Brakes vs Drum Brakes

Disc brakes offer superior stopping power and heat dissipation due to their exposed rotor design, making them ideal for high-performance and industrial applications requiring consistent braking under heavy loads. Drum brakes, with their enclosed drum and shoe mechanism, provide better protection against environmental contaminants and tend to be more cost-effective for lower-speed or lighter industrial machinery. Differences in maintenance complexity and heat management significantly influence the choice between disc and drum brakes in industrial settings.

Key Components and Working Principles

Disc brakes consist of a rotor attached to the wheel and a caliper housing brake pads that clamp the rotor to create friction, converting kinetic energy into heat to slow or stop motion. Drum brakes feature a drum connected to the wheel, inside which brake shoes press outward against the drum's interior surface to generate friction and decelerate the system. Understanding these key components and their working principles helps you select the optimal braking technology for industrial applications based on performance, maintenance, and operating conditions.

Performance and Efficiency Comparison

Disc brakes provide superior heat dissipation and consistent stopping power under heavy industrial loads, resulting in better performance and reduced brake fade compared to drum brakes. Drum brakes, while typically more cost-effective, suffer from slower heat dissipation and potential brake fade during continuous or high-intensity use, lowering overall efficiency. Your choice should prioritize disc brakes for applications demanding reliable, high-performance braking and energy efficiency.

Heat Dissipation and Thermal Management

Disc brakes excel in heat dissipation due to their exposed rotor design, which allows better airflow and faster cooling compared to the enclosed drum brake system. Industrial applications benefit from disc brakes' superior thermal management, as reduced heat buildup prevents brake fade and maintains consistent stopping power under heavy load conditions. Your equipment's safety and performance improve significantly with disc brakes, especially in environments demanding frequent or prolonged braking cycles.

Maintenance and Longevity

Disc brakes in industrial settings offer easier maintenance due to their exposed design, enabling quicker inspection and replacement of pads without dismantling the entire wheel assembly. Drum brakes, while more enclosed and protected from contaminants, require more labor-intensive servicing and frequent adjustments to maintain optimal performance. Your choice between disc and drum brakes should consider the balance between maintenance accessibility and the expected longevity under your specific operational conditions.

Safety and Reliability Considerations

Disc brakes offer superior heat dissipation and consistent stopping power, enhancing safety and reliability in industrial applications. Drum brakes, while cost-effective, are more prone to brake fade under heavy loads due to heat buildup, which can compromise reliability. Industrial systems prioritizing high performance and frequent braking cycles typically favor disc brakes for their durability and consistent safety performance.

Cost Factors and Economic Impact

Disc brakes generally have higher upfront costs due to more complex manufacturing and materials, but their longer lifespan and superior performance reduce long-term maintenance expenses in industrial applications. Drum brakes are less expensive initially but often incur higher costs over time due to frequent adjustments and part replacements. Your choice impacts overall operational efficiency and budgeting, with disc brakes offering better economic value in high-demand environments.

Application Suitability in Industry

Disc brakes offer superior heat dissipation and consistent performance under heavy industrial loads, making them ideal for high-speed machinery and applications requiring frequent stopping. Drum brakes, while less expensive and providing strong holding power, are better suited to low-speed, less demanding environments such as conveyors and light-duty equipment. Industry sectors like manufacturing and mining often prefer disc brakes for their durability and reliability in harsh conditions.

Future Trends in Industrial Brake Technology

Future trends in industrial brake technology highlight the shift towards advanced disc brake systems due to their superior heat dissipation, consistent stopping power, and reduced maintenance requirements compared to traditional drum brakes. Innovations such as electronic braking controls, integration with predictive maintenance platforms, and the use of composite materials aim to enhance performance and durability in heavy-duty applications. Growth in automation and Industry 4.0 also drives demand for smart braking solutions that offer real-time diagnostics and adaptive braking capabilities to optimize industrial safety and efficiency.

Disc brake vs drum brake (industrial) Infographic

libmatt.com

libmatt.com