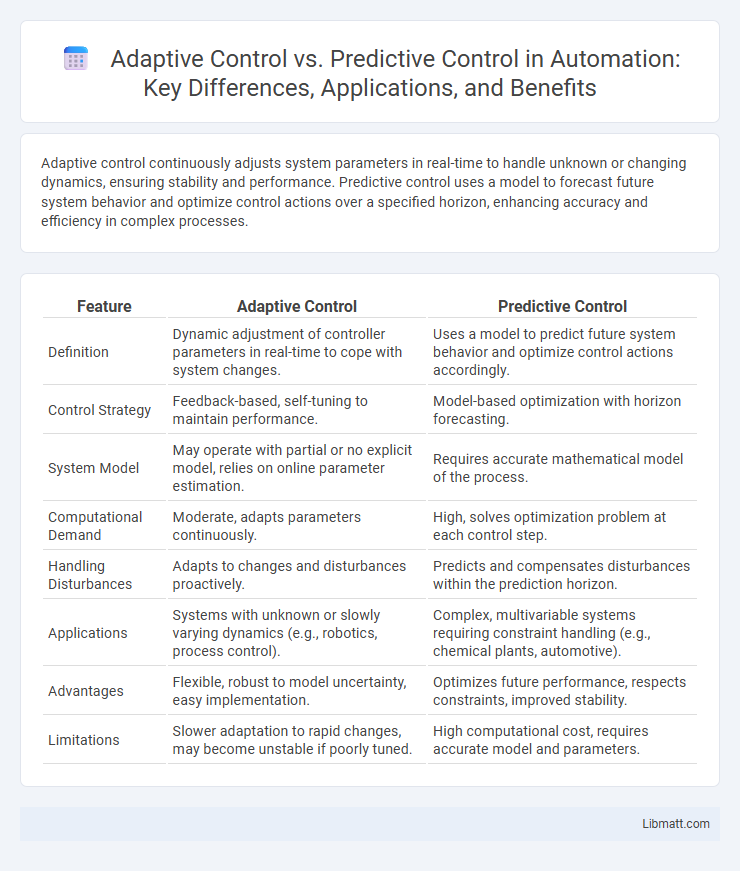

Adaptive control continuously adjusts system parameters in real-time to handle unknown or changing dynamics, ensuring stability and performance. Predictive control uses a model to forecast future system behavior and optimize control actions over a specified horizon, enhancing accuracy and efficiency in complex processes.

Table of Comparison

| Feature | Adaptive Control | Predictive Control |

|---|---|---|

| Definition | Dynamic adjustment of controller parameters in real-time to cope with system changes. | Uses a model to predict future system behavior and optimize control actions accordingly. |

| Control Strategy | Feedback-based, self-tuning to maintain performance. | Model-based optimization with horizon forecasting. |

| System Model | May operate with partial or no explicit model, relies on online parameter estimation. | Requires accurate mathematical model of the process. |

| Computational Demand | Moderate, adapts parameters continuously. | High, solves optimization problem at each control step. |

| Handling Disturbances | Adapts to changes and disturbances proactively. | Predicts and compensates disturbances within the prediction horizon. |

| Applications | Systems with unknown or slowly varying dynamics (e.g., robotics, process control). | Complex, multivariable systems requiring constraint handling (e.g., chemical plants, automotive). |

| Advantages | Flexible, robust to model uncertainty, easy implementation. | Optimizes future performance, respects constraints, improved stability. |

| Limitations | Slower adaptation to rapid changes, may become unstable if poorly tuned. | High computational cost, requires accurate model and parameters. |

Introduction to Adaptive and Predictive Control

Adaptive control continuously adjusts its parameters in real-time to maintain optimal system performance despite changing dynamics and uncertainties. Predictive control leverages a dynamic model to forecast future system behavior and determine optimal control actions by solving an optimization problem within constraints. Your choice between adaptive and predictive control depends on system requirements for flexibility, accuracy, and computational complexity.

Core Principles of Adaptive Control

Adaptive control uses real-time system feedback to adjust controller parameters dynamically, ensuring stability and performance despite uncertainties or changing conditions. It relies on parameter estimation algorithms and feedback mechanisms to modify control laws based on observed system behavior. This approach enables your system to continuously learn and adapt, maintaining optimal operation without requiring precise modeling in advance.

Fundamental Concepts of Predictive Control

Predictive control relies on a dynamic model of the process to forecast future behavior and optimize control moves by solving a finite horizon optimization problem. It incorporates constraints explicitly, enhancing performance and stability in multivariable systems with delays and nonlinearities. The core concept involves minimizing a cost function over predicted future outputs to ensure desired system response.

Key Differences Between Adaptive and Predictive Control

Adaptive control continuously adjusts controller parameters in real-time to handle system uncertainties and varying dynamics, while predictive control optimizes future control actions using a model and forecast over a finite horizon. Adaptive control excels in environments with unknown or changing system characteristics, whereas predictive control relies on accurate system models to predict and optimize future behavior. Understanding these key differences can help you select the appropriate control strategy for your dynamic system requirements.

Application Areas of Adaptive Control

Adaptive control is widely applied in aerospace for flight control systems where dynamic changes in the environment require real-time adjustments. It is also crucial in robotics and manufacturing processes to maintain performance despite system uncertainties and varying loads. Your ability to optimize complex industrial processes benefits significantly from adaptive control's flexibility in handling unknown or time-varying plant parameters.

Application Areas of Predictive Control

Predictive control is widely applied in industries requiring precise management of multivariable systems and constraints, such as chemical processing, oil refining, and power generation. Its ability to anticipate future system behavior based on dynamic models makes it ideal for optimizing energy efficiency and product quality in manufacturing plants. Your processes benefit from predictive control by maintaining stability and improving performance in complex, time-varying environments.

Advantages of Adaptive Control Systems

Adaptive control systems offer significant advantages in handling processes with unknown or time-varying dynamics by continuously adjusting controller parameters to maintain optimal performance. They excel in environments with model uncertainties and external disturbances, providing robustness and improved stability compared to fixed-parameter controllers. The ability to adapt parameters in real-time enhances system resilience, reduces steady-state errors, and improves transient response in complex industrial and aerospace applications.

Strengths of Predictive Control Strategies

Predictive control strategies excel in handling multivariable systems with constraints by optimizing future control actions based on a dynamic model, resulting in improved performance and system efficiency. Their ability to anticipate future disturbances and adjust actions accordingly provides superior robustness in complex industrial processes. You benefit from enhanced precision and stability, especially in applications requiring tight control and proactive adjustment to changing conditions.

Challenges in Implementation: Adaptive vs Predictive Control

Adaptive control faces challenges such as model uncertainty, parameter estimation accuracy, and real-time adjustment demands, which can lead to instability if not properly managed. Predictive control struggles with computational complexity, requiring significant processing power for real-time optimization and accurate system modeling to maintain performance. Both methods demand robust design to handle nonlinearity, disturbances, and system constraints effectively in practical applications.

Future Trends in Control System Technologies

Adaptive control systems are evolving with enhanced machine learning algorithms that improve real-time parameter adjustment, enabling more efficient handling of dynamic uncertainties in industrial processes. Predictive control technologies increasingly incorporate advanced model predictive control (MPC) techniques combined with AI-driven forecasting to optimize future system behavior and resource allocation. Your ability to integrate these future trends can significantly enhance control system accuracy, flexibility, and energy efficiency in complex applications.

Adaptive Control vs Predictive Control Infographic

libmatt.com

libmatt.com