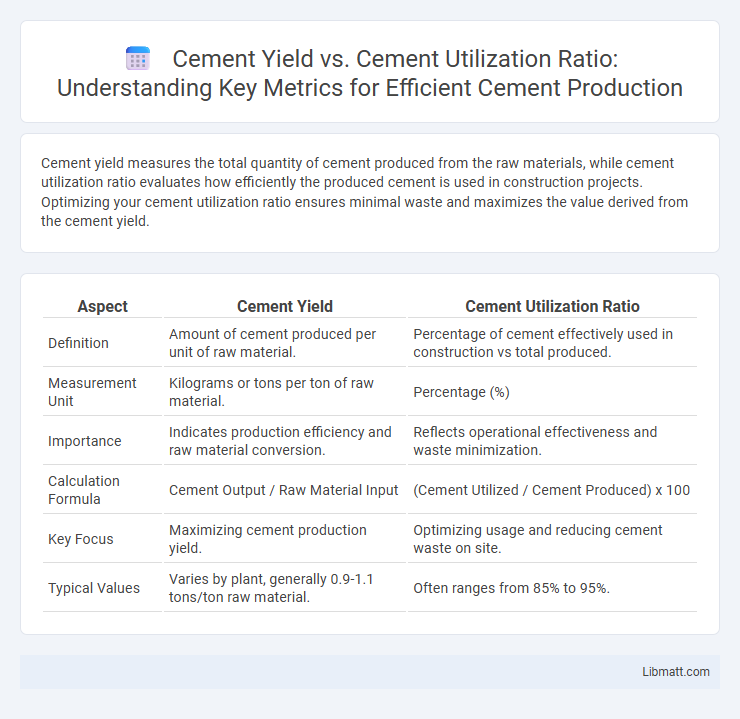

Cement yield measures the total quantity of cement produced from the raw materials, while cement utilization ratio evaluates how efficiently the produced cement is used in construction projects. Optimizing your cement utilization ratio ensures minimal waste and maximizes the value derived from the cement yield.

Table of Comparison

| Aspect | Cement Yield | Cement Utilization Ratio |

|---|---|---|

| Definition | Amount of cement produced per unit of raw material. | Percentage of cement effectively used in construction vs total produced. |

| Measurement Unit | Kilograms or tons per ton of raw material. | Percentage (%) |

| Importance | Indicates production efficiency and raw material conversion. | Reflects operational effectiveness and waste minimization. |

| Calculation Formula | Cement Output / Raw Material Input | (Cement Utilized / Cement Produced) x 100 |

| Key Focus | Maximizing cement production yield. | Optimizing usage and reducing cement waste on site. |

| Typical Values | Varies by plant, generally 0.9-1.1 tons/ton raw material. | Often ranges from 85% to 95%. |

Introduction to Cement Yield and Utilization Ratio

Cement yield refers to the amount of cement product obtained from a given quantity of raw materials, while the cement utilization ratio measures the efficiency of cement consumption in construction activities relative to total production. Understanding these metrics is crucial for optimizing production processes and minimizing waste in the cement industry. Accurate assessment of cement yield and utilization ratio helps enhance cost-effectiveness and resource management across construction projects.

Defining Cement Yield: Meaning and Importance

Cement yield refers to the volume of concrete or mortar produced per bag of cement, providing a practical measure of material efficiency during construction. Understanding cement yield is crucial for accurately estimating required materials, minimizing waste, and ensuring cost-effective project management. Precise calculation of cement yield directly impacts project timelines and quality by optimizing cement utilization ratios on site.

Understanding Cement Utilization Ratio

Cement Utilization Ratio measures the efficiency of cement usage by comparing the actual volume of cement consumed to the theoretical volume required for a specific construction task. It highlights discrepancies between cement yield and real consumption, helping to identify waste or inefficiencies during mixing, handling, and placement. Accurate assessment of this ratio ensures optimal material management, cost control, and quality assurance in concrete production.

Key Differences Between Cement Yield and Utilization Ratio

Cement yield measures the volume of concrete produced per bag of cement, highlighting efficiency in material usage, while the cement utilization ratio assesses the actual amount of cement used compared to the theoretical requirement for a mix design. The key difference lies in yield focusing on output volume relative to input, whereas utilization ratio emphasizes the accuracy and precision in cement dosage to optimize strength and cost. Understanding these metrics helps You improve mix efficiency and control material wastage on construction projects.

Factors Influencing Cement Yield

Cement yield is primarily influenced by the chemical composition of the raw materials and the fineness of the cement particles, which affect hydration and strength development. Moisture content, mixing methods, and curing conditions also play crucial roles in determining the effective yield of cement in concrete applications. Understanding these factors helps optimize your cement utilization ratio for improved structural performance and cost efficiency.

Factors Affecting Cement Utilization Ratio

Cement Utilization Ratio (CUR) is influenced by factors including mix design accuracy, batching precision, and quality of raw materials. Variations in water-cement ratio, aggregate gradation, and curing conditions significantly impact cement yield and utilization efficiency. Optimizing these parameters ensures maximum strength development and cost-effective cement usage in construction projects.

Calculation Methods: Cement Yield vs Utilization Ratio

Cement Yield is calculated by dividing the volume of concrete produced by the amount of cement used, reflecting the efficiency in converting cement into concrete. Cement Utilization Ratio measures the actual cement quantity consumed against the theoretical cement demand based on mix design, indicating the degree of cement consumption accuracy. Both metrics help optimize cement usage but target yield efficiency and consumption accuracy respectively in construction projects.

Impact of Yield and Utilization Ratio on Construction Projects

Cement yield directly affects the volume of concrete produced, influencing project timelines and cost efficiency by determining how much finished material can be obtained from a given quantity of cement. Cement utilization ratio measures the effective use of cement in mixing and setting processes, impacting the strength, durability, and overall quality of construction structures. Optimizing both yield and utilization ratio ensures resource efficiency, reduces wastage, and enhances the structural integrity of construction projects, leading to improved performance and budget management.

Optimizing Cement Yield and Utilization for Efficiency

Optimizing cement yield and utilization ratio enhances overall construction efficiency by minimizing material waste and reducing costs. Accurate measurement and control of cement usage ensure maximum strength and durability in concrete structures while preventing overuse or underuse of materials. By carefully managing your cement yield, you improve project sustainability and operational productivity.

Best Practices to Improve Cement Yield and Utilization Ratio

Optimizing cement yield and utilization ratio requires accurate proportioning of mix components, consistent batching procedures, and minimizing material wastage on site. Implementing advanced mixing technologies and regular calibration of batching equipment ensures uniform consistency and reduces segregation. Monitoring and controlling water-cement ratio and maintaining proper curing conditions directly enhance the final strength and durability of concrete, thereby improving overall cement usage efficiency.

Cement Yield vs Cement Utilization Ratio Infographic

libmatt.com

libmatt.com