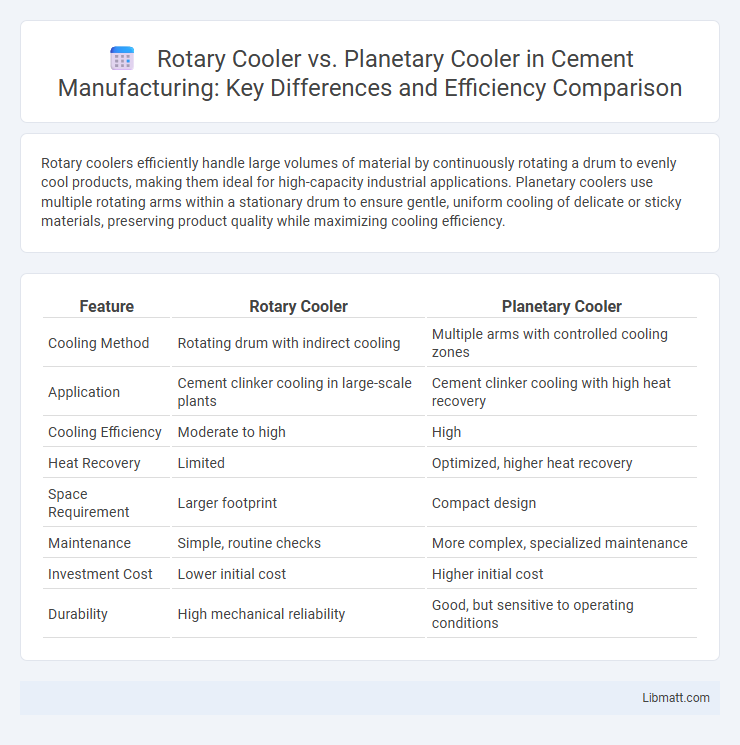

Rotary coolers efficiently handle large volumes of material by continuously rotating a drum to evenly cool products, making them ideal for high-capacity industrial applications. Planetary coolers use multiple rotating arms within a stationary drum to ensure gentle, uniform cooling of delicate or sticky materials, preserving product quality while maximizing cooling efficiency.

Table of Comparison

| Feature | Rotary Cooler | Planetary Cooler |

|---|---|---|

| Cooling Method | Rotating drum with indirect cooling | Multiple arms with controlled cooling zones |

| Application | Cement clinker cooling in large-scale plants | Cement clinker cooling with high heat recovery |

| Cooling Efficiency | Moderate to high | High |

| Heat Recovery | Limited | Optimized, higher heat recovery |

| Space Requirement | Larger footprint | Compact design |

| Maintenance | Simple, routine checks | More complex, specialized maintenance |

| Investment Cost | Lower initial cost | Higher initial cost |

| Durability | High mechanical reliability | Good, but sensitive to operating conditions |

Introduction to Rotary and Planetary Coolers

Rotary coolers utilize a rotating drum to ensure uniform cooling by continuously tumbling materials, making them ideal for handling bulk solids with moderate heat transfer requirements. Planetary coolers operate with multiple rotating arms within a stationary drum, offering enhanced cooling efficiency and faster heat dissipation suitable for fine or sticky materials. Both systems serve critical roles in process industries, selecting between them depends on material characteristics and desired cooling performance.

Working Principles of Rotary Coolers

Rotary coolers operate by rotating a drum or cylinder to ensure continuous mixing and efficient heat exchange between the material and cooling air or water. The material moves through the rotating drum, where surface exposure to cooling medium reduces temperature uniformly and prevents clumping or thermal degradation. Understanding your cooling requirements helps determine if the rotary cooler's uniform heat transfer and mechanical agitation meet your processing needs better than the planetary cooler's approach.

Working Principles of Planetary Coolers

Planetary coolers operate by rotating a cylindrical drum inside a stationary outer shell, causing the material to move through a tumbling action that promotes efficient heat exchange. This design allows uniform cooling as the material is lifted and dropped through the gas stream, enhancing heat transfer between the solid and the cooling medium. Your process benefits from the cooler's ability to handle fine particles and reduce dust emissions compared to rotary coolers.

Key Design Differences

Rotary coolers utilize a rotating drum to facilitate material cooling through continuous motion, enhancing heat transfer efficiency for bulk solids. Planetary coolers feature multiple mixing arms mounted on a rotating axis that intensively agitate materials to increase surface exposure and cooling rates. The key design difference lies in rotary coolers emphasizing indirect contact via drum rotation, while planetary coolers leverage intensive mechanical mixing for rapid temperature reduction.

Efficiency Comparison

Rotary coolers provide continuous material flow with efficient heat exchange, making them ideal for high-capacity operations requiring consistent temperature control. Planetary coolers, featuring rotating arms and a stationary drum, offer enhanced cooling efficiency by increasing wet material surface exposure and reducing cycle time. Your choice depends on balancing throughput needs and energy consumption, with rotary coolers excelling in bulk cooling and planetary coolers optimizing heat transfer for sticky or easily agglomerated materials.

Maintenance Requirements

Rotary Coolers require regular inspection of the rotating drum and seals to prevent wear and ensure efficient cooling, with maintenance often involving lubrication of bearings and replacement of worn parts. Planetary Coolers generally have simpler maintenance needs due to fewer moving parts, but periodic checks of gear systems and cooling fins are essential to maintain optimal performance. Your choice should consider the ease of access for routine servicing and availability of spare parts for long-term operational efficiency.

Energy Consumption Analysis

Rotary coolers typically consume more energy due to continuous drum rotation and longer cooling cycles, resulting in higher operational costs compared to planetary coolers. Planetary coolers, with their efficient heat exchange design and intermittent mixing, optimize airflow and temperature distribution, reducing energy consumption by up to 30%. Your choice in cooler can significantly impact energy efficiency, with planetary coolers offering a more sustainable option for industrial cooling needs.

Applications in Industry

Rotary coolers are widely used in industries requiring continuous cooling of granular and powder materials, such as cement, minerals, and chemicals, due to their ability to handle large volumes efficiently. Planetary coolers find applications in industries with delicate materials like fertilizers and food products, where gentle cooling without material degradation is crucial. Your choice between these coolers depends on the specific cooling requirements, material properties, and production scale in industrial processes.

Cost Considerations

Rotary coolers generally have lower initial costs due to simpler design and construction, making them suitable for budget-conscious projects. Planetary coolers, while more expensive upfront, offer better heat transfer efficiency and reduced maintenance expenses over time, potentially lowering total cost of ownership. Your choice should balance immediate budget constraints with long-term operational savings for optimal investment.

Choosing the Right Cooler for Your Process

Choosing the right cooler for your process depends on the specific requirements of heat transfer efficiency and material handling. Rotary coolers excel in continuous cooling applications with granular or bulk materials, providing uniform temperature control and high throughput. Planetary coolers offer precise temperature management for sensitive products, minimizing degradation through gentle handling and improved heat exchange surface area.

Rotary Cooler vs Planetary Cooler Infographic

libmatt.com

libmatt.com