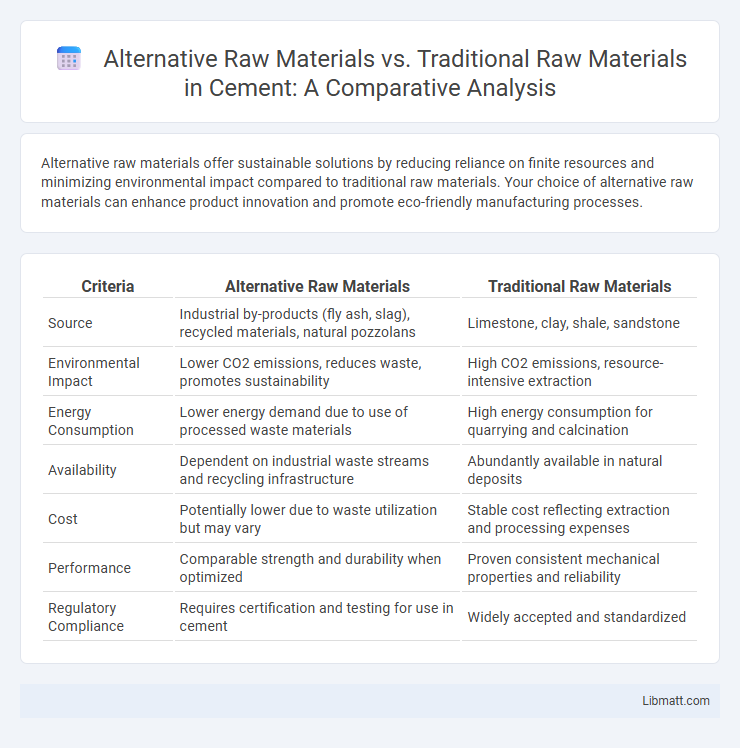

Alternative raw materials offer sustainable solutions by reducing reliance on finite resources and minimizing environmental impact compared to traditional raw materials. Your choice of alternative raw materials can enhance product innovation and promote eco-friendly manufacturing processes.

Table of Comparison

| Criteria | Alternative Raw Materials | Traditional Raw Materials |

|---|---|---|

| Source | Industrial by-products (fly ash, slag), recycled materials, natural pozzolans | Limestone, clay, shale, sandstone |

| Environmental Impact | Lower CO2 emissions, reduces waste, promotes sustainability | High CO2 emissions, resource-intensive extraction |

| Energy Consumption | Lower energy demand due to use of processed waste materials | High energy consumption for quarrying and calcination |

| Availability | Dependent on industrial waste streams and recycling infrastructure | Abundantly available in natural deposits |

| Cost | Potentially lower due to waste utilization but may vary | Stable cost reflecting extraction and processing expenses |

| Performance | Comparable strength and durability when optimized | Proven consistent mechanical properties and reliability |

| Regulatory Compliance | Requires certification and testing for use in cement | Widely accepted and standardized |

Introduction to Raw Materials: Traditional vs. Alternative

Traditional raw materials, such as wood, oil, and minerals, have been the backbone of manufacturing and industry for centuries, offering proven reliability and established supply chains. Alternative raw materials, derived from renewable resources or recycled content, provide sustainable options that reduce environmental impact and promote circular economies. Understanding the differences between these materials helps you make informed choices for greener production and innovation.

Defining Traditional Raw Materials

Traditional raw materials refer to natural resources such as timber, cotton, iron ore, and crude oil that have been used for centuries across various industries including construction, textile manufacturing, and energy production. These materials are typically extracted directly from the environment and processed through established methods to create finished goods or intermediate products. Their consistent availability and well-understood properties make traditional raw materials essential for maintaining industrial stability and meeting global demand.

What are Alternative Raw Materials?

Alternative raw materials are sustainable or renewable substances used in manufacturing processes to replace conventional resources like petroleum, minerals, or timber. These materials often include agricultural residues, recycled plastics, bio-based polymers, and industrial by-products, reducing environmental impact and dependency on finite resources. Their integration supports circular economy principles and helps industries lower carbon footprints while maintaining product quality.

Advantages of Traditional Raw Materials

Traditional raw materials offer consistent quality and proven reliability in manufacturing processes, ensuring stability and predictability in production outcomes. Their extensive availability and established supply chains reduce costs and minimize risks related to sourcing disruptions. For your operations, relying on traditional raw materials can enhance product uniformity and compliance with industry standards.

Benefits of Alternative Raw Materials

Alternative raw materials offer significant environmental advantages by reducing dependency on finite natural resources, thereby promoting sustainability and minimizing ecological footprints. They often provide cost savings through the use of recycled or abundant materials, enhancing economic efficiency in production processes. Moreover, alternative raw materials can improve product innovation and performance by enabling the development of novel composites and sustainable solutions.

Environmental Impact: Traditional vs. Alternative

Traditional raw materials often result in higher carbon emissions and resource depletion due to extensive mining and extraction processes. Alternative raw materials, such as recycled or bio-based inputs, significantly reduce environmental impact by lowering energy consumption and minimizing waste generation. Incorporating alternative raw materials into your production can enhance sustainability and reduce your ecological footprint.

Economic Considerations and Cost Efficiency

Alternative raw materials often provide significant cost savings compared to traditional raw materials due to lower procurement expenses and reduced environmental compliance costs. Economic considerations favor alternatives that enhance supply chain resilience by mitigating price volatility linked to conventional sources. Cost efficiency is further optimized through reduced energy consumption and waste generation in processing alternative materials, leading to long-term financial benefits for manufacturers.

Industrial Applications: Comparing Utilization

Alternative raw materials, such as recycled plastics, bio-based chemicals, and agricultural waste, are increasingly utilized across industrial applications for their sustainability and cost-effectiveness. Traditional raw materials like petroleum-based products, minerals, and metal ores dominate sectors requiring high purity and consistent performance, including petrochemicals and heavy manufacturing. Your choice between alternative and traditional raw materials depends on factors like environmental impact, regulatory compliance, and specific process requirements in industries such as automotive, construction, and packaging.

Challenges in Shifting to Alternative Raw Materials

Shifting to alternative raw materials presents significant challenges, including higher initial costs, supply chain instability, and inconsistent quality compared to traditional raw materials. You may encounter regulatory hurdles and the need for extensive research and development to adapt existing manufacturing processes. Ensuring scalability and maintaining product performance remain critical concerns in adopting these sustainable alternatives.

Future Trends and Innovations in Raw Material Sourcing

Future trends in raw material sourcing emphasize the rising adoption of alternative raw materials such as bio-based polymers, recycled metals, and agricultural residues to reduce environmental impact and enhance sustainability. Innovations in material science and circular economy models drive the development of eco-friendly alternatives, promoting resource efficiency and reducing dependency on finite traditional raw materials like petroleum-based plastics and virgin minerals. Advances in biotechnology, nanotechnology, and digital supply chain management are reshaping raw material procurement by enabling smarter, greener, and more resilient sourcing strategies for industries worldwide.

Alternative Raw Materials vs Traditional Raw Materials Infographic

libmatt.com

libmatt.com