Crusher jaw plates are designed to handle heavy impact and crushing of large materials in jaw crushers, providing durability and resistance to wear during primary crushing. Crusher blow bars, used in impact crushers, focus on delivering high-impact force to break down softer or medium-hard materials efficiently, with your choice depending on the crusher type and specific material processing needs.

Table of Comparison

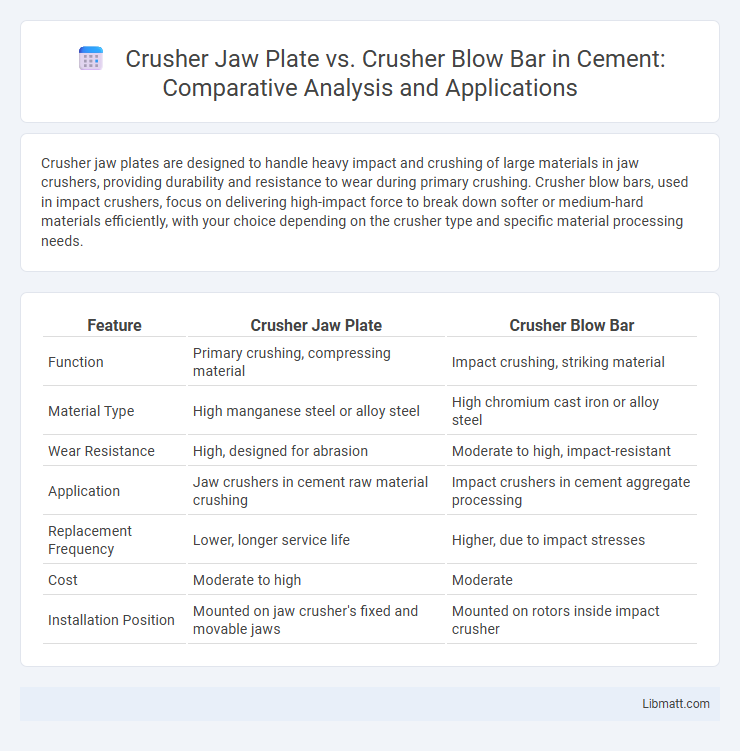

| Feature | Crusher Jaw Plate | Crusher Blow Bar |

|---|---|---|

| Function | Primary crushing, compressing material | Impact crushing, striking material |

| Material Type | High manganese steel or alloy steel | High chromium cast iron or alloy steel |

| Wear Resistance | High, designed for abrasion | Moderate to high, impact-resistant |

| Application | Jaw crushers in cement raw material crushing | Impact crushers in cement aggregate processing |

| Replacement Frequency | Lower, longer service life | Higher, due to impact stresses |

| Cost | Moderate to high | Moderate |

| Installation Position | Mounted on jaw crusher's fixed and movable jaws | Mounted on rotors inside impact crusher |

Introduction to Crusher Jaw Plate and Crusher Blow Bar

Crusher jaw plates are essential components in jaw crushers, designed to crush materials by applying compressive force between fixed and moving plates, typically made from high manganese steel for durability. Crusher blow bars are key wear parts in impact crushers, designed to impart kinetic energy to materials by striking them with high-impact force, commonly manufactured from manganese steel or chromium alloys to withstand repeated impacts. Both components play crucial roles in mining and construction industries by ensuring efficient material reduction through different mechanical actions.

Material Composition of Jaw Plate vs Blow Bar

Crusher jaw plates are typically made from high-manganese steel, which offers excellent wear resistance and toughness to withstand the heavy compressive forces during crushing. Blow bars are often composed of manganese steel or chromium alloy steel, engineered for impact resistance and durability in high-impact crushing applications. Your choice between the two depends on matching the material composition to the specific crushing environment and wear conditions.

Design Differences Between Jaw Plate and Blow Bar

Jaw plates feature a stationary and a movable design, with their curved, serrated surfaces optimized for crushing materials through compression and crushing force. Blow bars possess a swinging impact mechanism with a smooth, convex surface designed to deliver high-impact blows for shattering materials efficiently. Understanding these design differences helps you select the right component for your crusher system, ensuring optimal performance and durability.

Applications: When to Use Jaw Plate vs Blow Bar

Jaw plates are ideal for primary crushing applications where hard, abrasive materials like granite or ore need to be broken down into smaller pieces. Blow bars are best suited for impact crushers used in secondary crushing stages to process softer materials such as limestone or coal, providing high-impact force to fracture them efficiently. You should choose jaw plates for heavy-duty, coarse crushing tasks and blow bars for efficient, high-impact material reduction in softer, less abrasive applications.

Wear Resistance and Durability Comparison

Crusher jaw plates and crusher blow bars differ significantly in wear resistance and durability, with jaw plates typically made from manganese steel designed to withstand high compressive forces and continuous crushing cycles. Blow bars, often manufactured from high-chromium alloys or manganese steel, provide superior abrasion resistance against impact loads and are essential for breaking down softer, less abrasive materials. Your equipment's performance depends on selecting the correct component, balancing wear resistance and durability to optimize operational efficiency and minimize maintenance downtime.

Maintenance Requirements: Jaw Plate vs Blow Bar

Crusher jaw plates require regular inspection for wear and timely replacement to maintain optimal crushing performance, as they endure constant compressive forces. Blow bars demand more frequent maintenance due to exposure to high-impact forces, often involving quick replacement to prevent damage to the rotor and ensure efficient crushing. Properly maintaining your crusher's jaw plates and blow bars helps extend equipment lifespan and reduces downtime.

Cost Analysis: Jaw Plate vs Blow Bar

Jaw plates generally have a longer lifespan than blow bars, which can reduce replacement frequency and overall maintenance costs for your crushing equipment. Blow bars experience higher wear due to constant impact, leading to more frequent replacements and increased operational expenses. Evaluating the cost efficiency between crusher jaw plates and blow bars requires considering material durability, wear rate, and downtime associated with each component.

Impact on Crushing Efficiency

Crusher jaw plates and crusher blow bars significantly influence crushing efficiency through their unique interaction with materials. Jaw plates, designed for compressive force, optimize efficiency by enabling precise material gripping and breaking, especially in primary crushing stages. Blow bars, used in impact crushers, enhance efficiency by generating high-impact energy, effectively shattering materials and improving particle size distribution for secondary or tertiary crushing.

Common Failure Modes and Solutions

Crusher jaw plates commonly experience wear and cracking due to repetitive compressive forces, while crusher blow bars often suffer from impact fractures and surface abrasion caused by high-speed collisions with materials. Solutions include selecting abrasion-resistant alloy steel for jaw plates to enhance durability and implementing regular impact-resistant maintenance checks for blow bars to prevent unexpected failures. Your equipment's lifespan improves significantly by addressing these specific failure modes with targeted material upgrades and timely inspections.

Choosing the Right Option for Your Crushing Operation

Selecting the right crusher component hinges on the material type and crushing stage, with jaw plates ideal for primary crushing of hard, abrasive rocks due to their durability and wear resistance, while blow bars fit secondary crushers handling less abrasive materials for effective impact crushing. Jaw plates feature robust manganese steel composition, optimizing strength and lifespan under high-pressure conditions, whereas blow bars are designed from high-chrome cast iron or alloy steel to withstand repetitive impact forces. Evaluating operational conditions, feed size, and desired output shape ensures the best match, maximizing efficiency and reducing downtime in your crushing process.

Crusher Jaw Plate vs Crusher Blow Bar Infographic

libmatt.com

libmatt.com