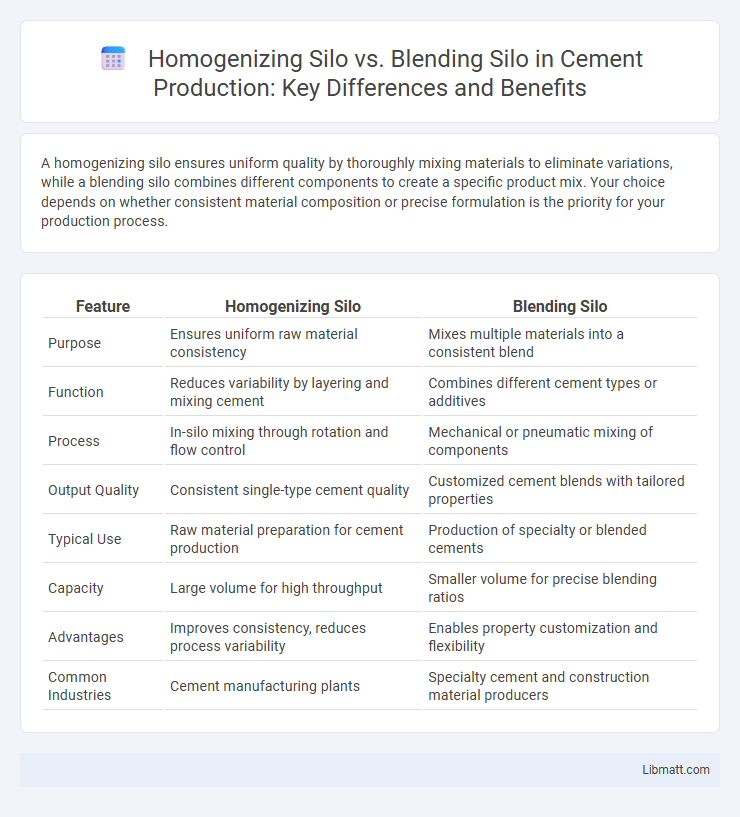

A homogenizing silo ensures uniform quality by thoroughly mixing materials to eliminate variations, while a blending silo combines different components to create a specific product mix. Your choice depends on whether consistent material composition or precise formulation is the priority for your production process.

Table of Comparison

| Feature | Homogenizing Silo | Blending Silo |

|---|---|---|

| Purpose | Ensures uniform raw material consistency | Mixes multiple materials into a consistent blend |

| Function | Reduces variability by layering and mixing cement | Combines different cement types or additives |

| Process | In-silo mixing through rotation and flow control | Mechanical or pneumatic mixing of components |

| Output Quality | Consistent single-type cement quality | Customized cement blends with tailored properties |

| Typical Use | Raw material preparation for cement production | Production of specialty or blended cements |

| Capacity | Large volume for high throughput | Smaller volume for precise blending ratios |

| Advantages | Improves consistency, reduces process variability | Enables property customization and flexibility |

| Common Industries | Cement manufacturing plants | Specialty cement and construction material producers |

Introduction to Homogenizing and Blending Silos

Homogenizing silos are designed to ensure uniformity by thoroughly mixing and equalizing the composition of stored bulk materials, preventing segregation and settling. Blending silos focus on combining different raw materials or components to achieve a consistent blend before processing or packaging. Both types of silos optimize material consistency, but homogenizing silos emphasize quality stabilization, while blending silos concentrate on precise formulation.

Key Functions of Homogenizing Silos

Homogenizing silos are designed to ensure consistent material quality by mixing and equalizing product properties such as moisture, density, and particle size, preventing segregation. They feature internal mixing mechanisms that circulate bulk solids, improving uniformity before downstream processing or packaging. Unlike blending silos that combine different raw materials, homogenizing silos focus on uniformity within a single product batch to optimize production efficiency and end-product quality.

Primary Roles of Blending Silos

Blending silos primarily serve to combine different raw materials or components to create a uniform, consistent mixture that meets precise product specifications in industries such as cement, pharmaceuticals, and food processing. They ensure accurate proportioning of ingredients, maintaining quality control by homogenizing diverse input materials to achieve desired chemical and physical properties before further processing. Unlike homogenizing silos that focus on uniformity within a single material batch, blending silos optimize mixture composition and consistency across multiple material streams.

Design Differences: Homogenizing vs Blending Silos

Homogenizing silos feature internal mixing mechanisms such as rotating arms or agitators to create uniformity by continuously stirring the material, ensuring consistent quality and particle distribution throughout the storage. Blending silos rely on controlled layering and gradual intermixing without mechanical agitation, using design elements like multiple inlets and strategically shaped compartments to achieve material uniformity. The primary design difference lies in active mixing within homogenizing silos versus passive blending driven by material flow patterns in blending silos.

Material Flow Patterns in Each Silo Type

Homogenizing silos create a radial and vertical mixing pattern where raw materials continuously flow from the center to the periphery, promoting uniformity throughout the batch. Blending silos rely on axial flow patterns, moving materials primarily along the vertical axis to mix different components without extensive re-circulation. Understanding these material flow patterns is crucial to optimize your process and achieve consistent product quality.

Efficiency in Quality Control and Consistency

Homogenizing silos ensure high efficiency in quality control by thoroughly mixing materials to achieve uniform particle size and composition, reducing variability in the final product. Blending silos, while effective in combining different ingredients, may not achieve the same level of consistency due to less intensive mixing processes. Optimizing your production process with a homogenizing silo can enhance product reliability and maintain consistent quality standards.

Energy and Operational Cost Comparisons

Homogenizing silos typically consume less energy than blending silos due to their continuous mixing process, which reduces the need for frequent agitation and large motor loads. Operational costs are lower in homogenizing silos as they require fewer maintenance interventions and less manual oversight compared to blending silos that rely on batch processing and multiple mechanical components. Your choice between these silo types should consider these energy efficiencies and ongoing operational cost savings to optimize overall production expenses.

Industrial Applications: Which Silo for Which Material?

Homogenizing silos are ideal for maintaining consistent quality in bulk powders and granular materials such as cement, lime, and fly ash by thoroughly mixing and reducing material variability. Blending silos excel in combining different raw materials like minerals, fertilizers, and plastics to create a uniform final product with precise proportions. Your choice depends on whether the primary need is uniformity of a single material or the integration of multiple ingredients for industrial production.

Maintenance and Operational Challenges

Homogenizing silos require regular maintenance to ensure uniform material consistency and prevent segregation, often involving complex internal mixing mechanisms that increase operational complexity and downtime. Blending silos face challenges in maintaining precise ingredient ratios, demanding meticulous calibration of feeder systems and frequent monitoring to avoid contamination or segregation. Both silo types necessitate targeted cleaning protocols and equipment inspections to sustain product quality and minimize operational disruptions.

Choosing the Right Silo: Factors to Consider

Selecting the right silo involves evaluating key factors like material consistency, mixing requirements, and processing time. Homogenizing silos are ideal for achieving uniform particle distribution, ensuring product quality in industries like food and pharmaceuticals. Blending silos, however, prioritize combining different materials efficiently, suited for applications requiring diverse ingredient integration or formulation flexibility.

Homogenizing silo vs Blending silo Infographic

libmatt.com

libmatt.com