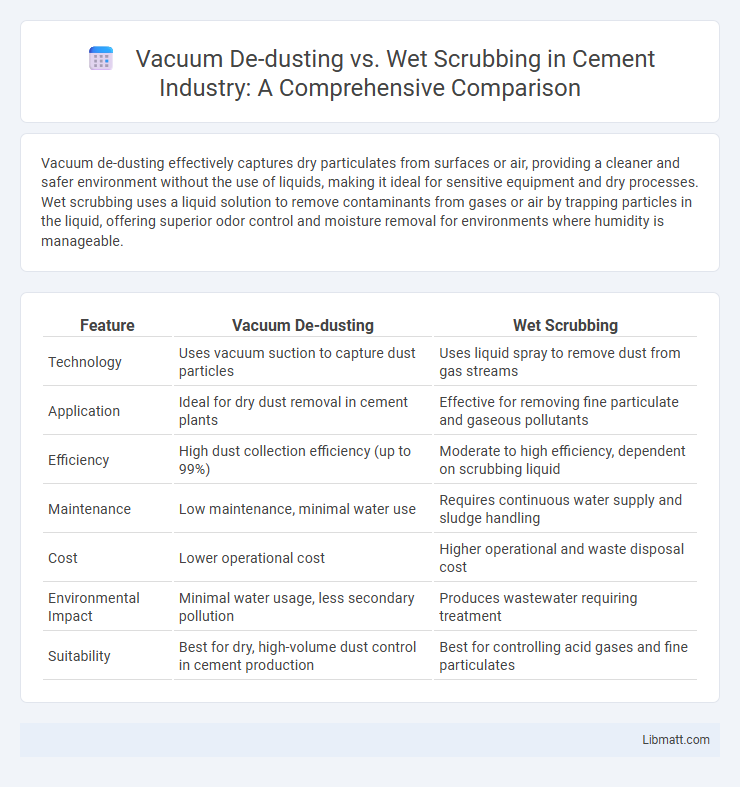

Vacuum de-dusting effectively captures dry particulates from surfaces or air, providing a cleaner and safer environment without the use of liquids, making it ideal for sensitive equipment and dry processes. Wet scrubbing uses a liquid solution to remove contaminants from gases or air by trapping particles in the liquid, offering superior odor control and moisture removal for environments where humidity is manageable.

Table of Comparison

| Feature | Vacuum De-dusting | Wet Scrubbing |

|---|---|---|

| Technology | Uses vacuum suction to capture dust particles | Uses liquid spray to remove dust from gas streams |

| Application | Ideal for dry dust removal in cement plants | Effective for removing fine particulate and gaseous pollutants |

| Efficiency | High dust collection efficiency (up to 99%) | Moderate to high efficiency, dependent on scrubbing liquid |

| Maintenance | Low maintenance, minimal water use | Requires continuous water supply and sludge handling |

| Cost | Lower operational cost | Higher operational and waste disposal cost |

| Environmental Impact | Minimal water usage, less secondary pollution | Produces wastewater requiring treatment |

| Suitability | Best for dry, high-volume dust control in cement production | Best for controlling acid gases and fine particulates |

Introduction to Industrial Dust Control Methods

Vacuum de-dusting systems use powerful suction to remove dust particles from industrial environments, ensuring cleaner air and improved worker safety. Wet scrubbing employs liquid sprays to capture and neutralize airborne dust, effectively reducing particulate emissions in processes with moisture-sensitive materials. Both methods are critical for maintaining regulatory compliance and enhancing air quality in various manufacturing and processing industries.

What is Vacuum De-dusting?

Vacuum de-dusting is an industrial dust control method that uses powerful suction to remove fine particulate matter directly from the air or surfaces, preventing airborne contamination. This dry technique is highly effective in environments where moisture-sensitive materials are handled, avoiding the use of liquids unlike wet scrubbing. It offers advantages in energy efficiency and easy waste disposal, especially in applications like mining, pharmaceuticals, and woodworking industries.

How Wet Scrubbing Works

Wet scrubbing works by passing contaminated air through a liquid solution, usually water, which captures and removes dust, particulate matter, and pollutants from the air stream. This process relies on the interaction between the airborne particles and the scrubbing liquid, effectively trapping impurities in the liquid phase before the cleaned air is released. You benefit from the system's high efficiency in removing fine particulates and gases compared to vacuum de-dusting, which primarily uses suction to collect dust dry.

Key Differences Between Vacuum De-dusting and Wet Scrubbing

Vacuum de-dusting and wet scrubbing differ primarily in their dust removal methods; vacuum de-dusting uses suction to capture dry particulate matter, while wet scrubbing traps pollutants with liquid sprays. Vacuum de-dusting systems excel in environments requiring dry material handling and minimal moisture, whereas wet scrubbing is effective for removing soluble gases and sticky or oily particles. Your choice between these technologies depends on factors such as dust characteristics, environmental regulations, and the need for moisture control.

Efficiency Comparison: Particulate Removal Rates

Vacuum de-dusting systems typically achieve particulate removal efficiencies between 85% and 95%, making them highly effective for removing dust and fine particles from dry industrial processes. Wet scrubbing technology can often surpass 99% efficiency, especially for very fine particulate matter and gaseous pollutants, due to its ability to capture particles through liquid absorption and impaction. Your choice between these methods should consider the specific particulate size distribution and moisture tolerance of your process for optimal removal performance.

Health and Safety Impacts

Vacuum de-dusting systems effectively reduce airborne dust particles, minimizing respiratory hazards and promoting cleaner air quality in industrial environments. Wet scrubbing captures contaminants by using liquid solutions, which lowers the risk of dust explosions but may introduce slip hazards and chemical exposure concerns. Your choice between these methods should consider the specific health and safety requirements of your facility, including dust concentration levels and potential chemical interactions.

Maintenance Requirements and Costs

Vacuum de-dusting systems generally require less maintenance due to fewer moving parts and no need for water treatment, leading to lower operational costs. Wet scrubbing involves regular monitoring of liquid levels, chemical usage, and disposal of contaminated water, which increases maintenance complexity and expenses. Understanding these differences can help you optimize your dust control budget and minimize downtime.

Environmental Considerations

Vacuum de-dusting systems minimize water usage and prevent secondary pollution by capturing dust particles dry, making them environmentally friendly for dry particulate control. Wet scrubbing effectively removes fine particulate and gaseous pollutants but generates wastewater requiring proper treatment to avoid environmental contamination. Your choice should consider local water availability and waste disposal regulations to ensure sustainable air pollution control.

Best Applications for Each Method

Vacuum de-dusting is ideal for dry dust removal in industries like pharmaceuticals, electronics, and woodworking, where precise, dry particulate control is essential. Wet scrubbing excels in chemical plants and metal processing, effectively capturing gaseous pollutants and sticky dust through liquid absorption. Your choice depends on the specific type of contaminants and industry requirements, ensuring optimal air quality management.

Choosing the Right Solution for Your Facility

Vacuum de-dusting offers precise particulate removal with minimal water usage, making it ideal for facilities emphasizing dry dust control and low environmental impact. Wet scrubbing excels at capturing fine dust and gaseous pollutants through liquid absorption, suitable for operations requiring comprehensive air purification and humidity control. Evaluating your facility's specific dust composition, regulatory requirements, and maintenance capabilities is essential to select the most effective dust control solution.

Vacuum De-dusting vs Wet Scrubbing Infographic

libmatt.com

libmatt.com