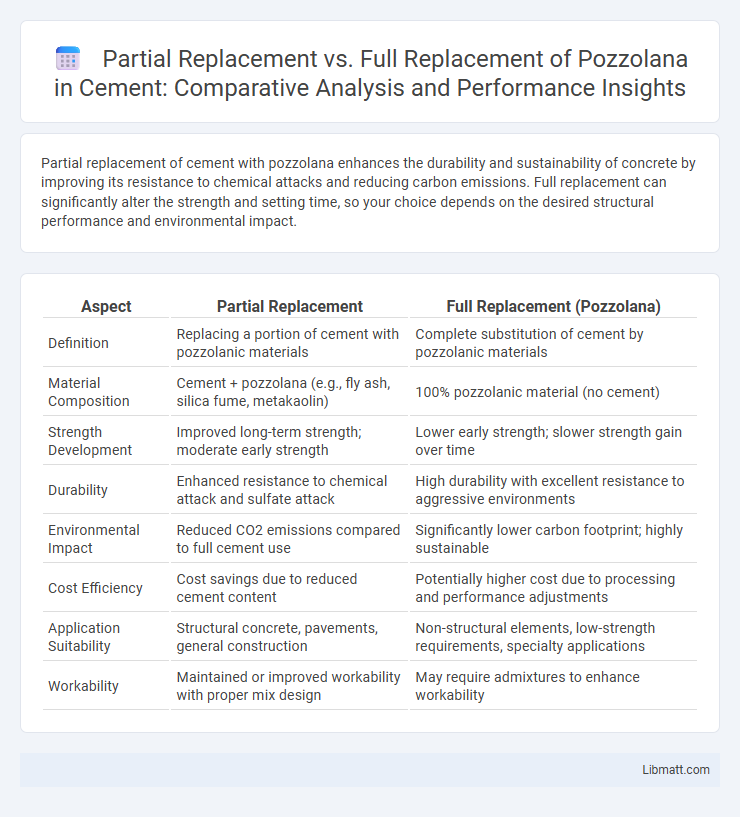

Partial replacement of cement with pozzolana enhances the durability and sustainability of concrete by improving its resistance to chemical attacks and reducing carbon emissions. Full replacement can significantly alter the strength and setting time, so your choice depends on the desired structural performance and environmental impact.

Table of Comparison

| Aspect | Partial Replacement | Full Replacement (Pozzolana) |

|---|---|---|

| Definition | Replacing a portion of cement with pozzolanic materials | Complete substitution of cement by pozzolanic materials |

| Material Composition | Cement + pozzolana (e.g., fly ash, silica fume, metakaolin) | 100% pozzolanic material (no cement) |

| Strength Development | Improved long-term strength; moderate early strength | Lower early strength; slower strength gain over time |

| Durability | Enhanced resistance to chemical attack and sulfate attack | High durability with excellent resistance to aggressive environments |

| Environmental Impact | Reduced CO2 emissions compared to full cement use | Significantly lower carbon footprint; highly sustainable |

| Cost Efficiency | Cost savings due to reduced cement content | Potentially higher cost due to processing and performance adjustments |

| Application Suitability | Structural concrete, pavements, general construction | Non-structural elements, low-strength requirements, specialty applications |

| Workability | Maintained or improved workability with proper mix design | May require admixtures to enhance workability |

Introduction to Pozzolana in Concrete

Pozzolana in concrete refers to natural or artificial materials containing silica and alumina that react chemically with calcium hydroxide to form compounds with cementitious properties, enhancing strength and durability. Partial replacement with pozzolana improves concrete's resistance to chemical attack and reduces permeability, while full replacement can significantly alter setting times and mechanical performance. Understanding the correct proportion of pozzolana in Your mix design is essential for optimizing concrete's longevity and environmental sustainability.

Understanding Partial Replacement of Pozzolana

Partial replacement of cement with pozzolana involves substituting a portion of cement with pozzolanic materials such as fly ash, silica fume, or rice husk ash, which react with calcium hydroxide to enhance concrete durability and strength. This method improves the sustainability of construction by reducing cement consumption and lowering carbon emissions without compromising the mechanical properties of your concrete mix. Understanding the optimal percentage of partial replacement is crucial to maximize the benefits of pozzolana while maintaining desired workability and setting times.

Full Replacement: Definition and Process

Full replacement in pozzolana applications involves substituting 100% of Portland cement with pozzolanic materials such as fly ash, silica fume, or volcanic ash, enhancing sustainability and reducing carbon emissions. This process requires precise mix design adjustments to maintain concrete performance, often incorporating activators or supplementary cementitious materials to achieve desired strength and durability. Key benefits include improved resistance to chemical attack, reduced heat of hydration, and increased long-term strength development in concrete structures.

Chemical and Physical Properties of Pozzolana

Pozzolana exhibits chemical properties characterized by high silica (SiO2) and alumina (Al2O3) content, which react with calcium hydroxide in the presence of water to form cementitious compounds. Its physical properties include fine particle size and large surface area, enhancing its pozzolanic reactivity and improving the microstructure of blended cement. Partial replacement of cement with pozzolana optimizes durability and reduces CO2 emissions, while full replacement demands careful control of curing conditions to achieve comparable strength.

Comparative Analysis: Strength Development

Partial replacement of cement with pozzolana typically results in slower initial strength development compared to full replacement due to reduced early hydration rates. Full replacement enhances long-term strength by increasing pozzolanic reactions that refine the microstructure and improve durability over time. Your choice between partial and full replacement impacts the balance between early strength gains and sustained strength performance in concrete applications.

Durability and Long-Term Performance

Partial replacement of cement with pozzolana enhances durability by reducing permeability and improving resistance to chemical attacks, thus extending the lifespan of concrete structures. Full replacement may lead to lower early strength but offers superior long-term performance due to continued pozzolanic activity that refines the microstructure. Optimizing the proportion of pozzolana is critical to balancing early strength and maximizing durability for sustainable concrete applications.

Economic Implications: Cost-Benefit Analysis

Partial replacement of cement with pozzolana reduces material costs by lowering cement consumption, leading to significant savings without compromising concrete strength. Full replacement may further decrease expenses but can require additives or processing to maintain performance, potentially offsetting initial savings. Cost-benefit analysis reveals partial replacement as the optimal balance between economic efficiency and structural integrity in construction projects.

Environmental Impact and Sustainability

Partial replacement of cement with pozzolanic materials significantly reduces carbon emissions by lowering clinker content, enhancing sustainability in construction projects. Full replacement offers even greater environmental benefits by minimizing resource depletion and waste generation, but requires careful consideration of mechanical performance and curing times. Your choice between partial and full replacement should balance ecological advantages with structural requirements to optimize both sustainability and durability.

Practical Considerations in Construction

Practical considerations in construction dictate that partial replacement with pozzolana enhances durability by improving workability and reducing permeability, making it suitable for projects demanding longer life spans and environmental benefits. Full replacement can significantly lower carbon footprint but may require additional curing time and careful quality control to ensure consistent strength for structural applications. Your choice depends on project timelines, environmental goals, and the specific performance requirements of the concrete mix.

Recommendations and Best Practices

Partial replacement of cement with pozzolana is recommended to enhance durability and reduce carbon footprint while maintaining adequate strength, typically replacing 15-30% by weight. Full replacement should only be considered in niche applications with rigorous quality control due to slower strength development and variability in pozzolanic materials. Best practices include optimizing mix design with proper curing methods and sourcing high-quality, reactive pozzolanic materials to maximize performance benefits.

Partial Replacement vs Full Replacement (Pozzolana) Infographic

libmatt.com

libmatt.com