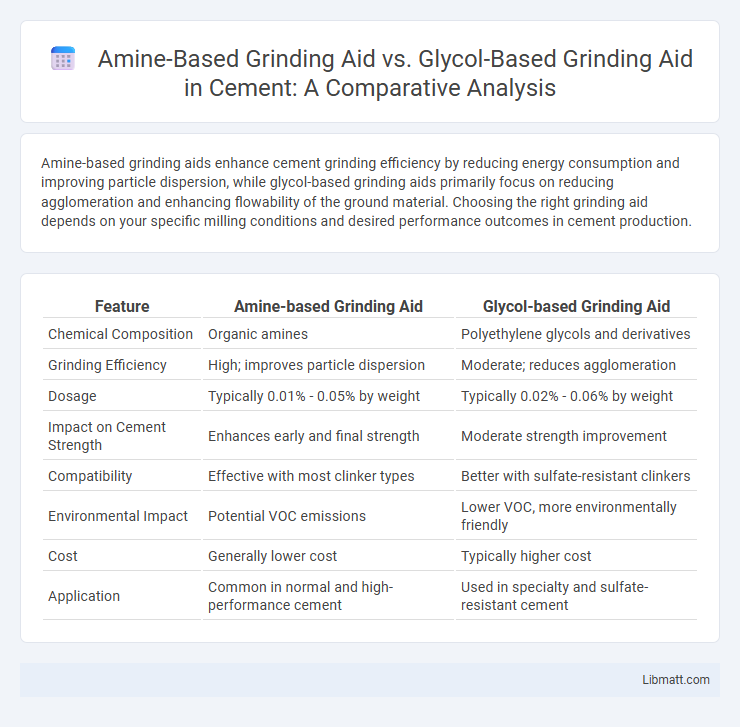

Amine-based grinding aids enhance cement grinding efficiency by reducing energy consumption and improving particle dispersion, while glycol-based grinding aids primarily focus on reducing agglomeration and enhancing flowability of the ground material. Choosing the right grinding aid depends on your specific milling conditions and desired performance outcomes in cement production.

Table of Comparison

| Feature | Amine-based Grinding Aid | Glycol-based Grinding Aid |

|---|---|---|

| Chemical Composition | Organic amines | Polyethylene glycols and derivatives |

| Grinding Efficiency | High; improves particle dispersion | Moderate; reduces agglomeration |

| Dosage | Typically 0.01% - 0.05% by weight | Typically 0.02% - 0.06% by weight |

| Impact on Cement Strength | Enhances early and final strength | Moderate strength improvement |

| Compatibility | Effective with most clinker types | Better with sulfate-resistant clinkers |

| Environmental Impact | Potential VOC emissions | Lower VOC, more environmentally friendly |

| Cost | Generally lower cost | Typically higher cost |

| Application | Common in normal and high-performance cement | Used in specialty and sulfate-resistant cement |

Introduction to Grinding Aids in Cement Production

Grinding aids enhance cement production by improving the efficiency of the grinding process and boosting the quality of the final product. Amine-based grinding aids chemically reduce particle agglomeration, leading to better cement dispersion and energy savings, while glycol-based grinding aids primarily act by altering slurry properties to improve grinding fluidity and reduce energy consumption. Your choice between amine-based and glycol-based aids impacts grinding efficiency, cement strength, and operational costs.

Overview of Amine-Based Grinding Aids

Amine-based grinding aids enhance cement grinding efficiency by reducing particle agglomeration and improving mill throughput, primarily through their surfactant properties that modify the surface energy of cement particles. These aids also contribute to increased early strength development in concrete by promoting better particle dispersion compared to glycol-based grinding aids, which mainly focus on lubrication and grinding energy reduction. The chemical structure of amines allows stronger interaction with cement minerals, resulting in more efficient grinding and improved final product performance.

Overview of Glycol-Based Grinding Aids

Glycol-based grinding aids enhance cement production by reducing particle agglomeration and improving mill efficiency through better dispersion and lubrication of cement particles. These aids, often composed of polyethylene glycol or propylene glycol derivatives, contribute to energy savings and increased throughput in grinding processes. They are preferred in applications requiring improved workability and strength development in the final concrete mix.

Chemical Composition and Functional Mechanisms

Amine-based grinding aids primarily consist of fatty amines or their derivatives, which enhance particle dispersion by adsorbing onto cement clinker surfaces, thereby reducing agglomeration during milling. Glycol-based grinding aids contain glycols such as ethylene glycol or propylene glycol that function by modifying the surface tension of slurry and improving the flowability of the material. The amine compounds target electrostatic forces to improve grinding efficiency, while glycol compounds act mainly through viscosity reduction and plasticization to facilitate finer grinding.

Efficiency and Performance Comparison

Amine-based grinding aids enhance cement grinding efficiency by improving particle dispersion and reducing agglomeration, resulting in increased mill throughput and energy savings of up to 10%. Glycol-based grinding aids primarily act as plasticizers, improving workability but offering slightly lower grinding efficiency gains compared to amines. Overall, amine-based aids typically deliver superior grinding performance and cement strength enhancement in comparison to glycol-based alternatives.

Impact on Cement Quality and Properties

Amine-based grinding aids improve cement quality by enhancing particle dispersion and reducing agglomeration, resulting in increased early strength and improved workability. Glycol-based grinding aids contribute to better cement flowability and reduce water demand, which enhances final strength and durability of the hardened cement. Both types influence setting time differently, with amine-based aids typically accelerating setting, whereas glycol-based aids may slightly retard it to optimize performance.

Environmental and Health Considerations

Amine-based grinding aids typically have higher volatility and can emit harmful nitrogen oxides, posing respiratory risks and environmental concerns due to their potential for air pollution. Glycol-based grinding aids generally exhibit lower toxicity and reduced emissions, making them a more environmentally friendly option with fewer health hazards for workers. When selecting a grinding aid, Your choice should consider the trade-off between performance and the impact on air quality and occupational safety.

Cost Analysis and Economic Impact

Amine-based grinding aids generally exhibit higher upfront costs due to specialized chemical formulations, but their improved grinding efficiency and energy savings often lead to reduced overall production expenses. Glycol-based grinding aids tend to have lower initial costs but may offer less enhancement in mill throughput and energy consumption, potentially increasing long-term operational costs. Economic impact assessments favor amine-based aids when evaluating total cost of ownership, factoring in reduced power usage and increased cement quality that contribute to higher profitability.

Compatibility with Different Cement Types

Amine-based grinding aids exhibit excellent compatibility with various cement types, including Portland, blended, and composite cements, enhancing particle dispersion and reducing energy consumption during grinding. Glycol-based grinding aids are particularly effective with sulfate-resistant and high-alkali cements, improving grindability while maintaining cement strength and workability. Both grinding aids contribute to optimized grinding efficiency but should be selected based on specific cement compositions to ensure maximum performance benefits.

Future Trends in Grinding Aid Development

Amine-based grinding aids exhibit superior performance in enhancing cement grinding efficiency due to their strong adsorption on mineral surfaces, while glycol-based aids offer improved environmental profiles with biodegradable properties. Future trends focus on developing hybrid grinding aids that combine the energy-saving benefits of amines with the eco-friendliness of glycols, optimizing both grinding performance and sustainability. Your choice in grinding aid will increasingly depend on balancing environmental regulations with production efficiency in the evolving cement industry.

Amine-based grinding aid vs Glycol-based grinding aid Infographic

libmatt.com

libmatt.com