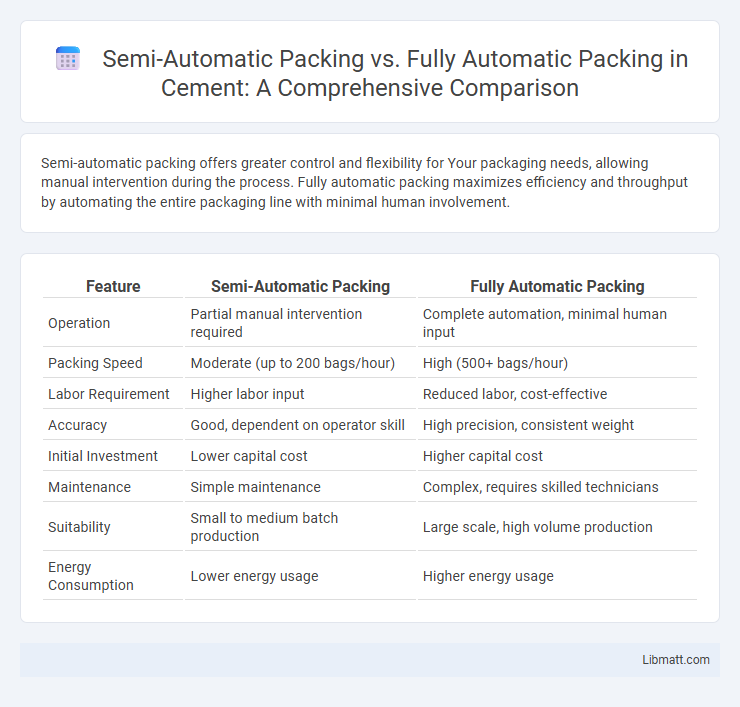

Semi-automatic packing offers greater control and flexibility for Your packaging needs, allowing manual intervention during the process. Fully automatic packing maximizes efficiency and throughput by automating the entire packaging line with minimal human involvement.

Table of Comparison

| Feature | Semi-Automatic Packing | Fully Automatic Packing |

|---|---|---|

| Operation | Partial manual intervention required | Complete automation, minimal human input |

| Packing Speed | Moderate (up to 200 bags/hour) | High (500+ bags/hour) |

| Labor Requirement | Higher labor input | Reduced labor, cost-effective |

| Accuracy | Good, dependent on operator skill | High precision, consistent weight |

| Initial Investment | Lower capital cost | Higher capital cost |

| Maintenance | Simple maintenance | Complex, requires skilled technicians |

| Suitability | Small to medium batch production | Large scale, high volume production |

| Energy Consumption | Lower energy usage | Higher energy usage |

Introduction to Packing Automation

Packing automation enhances efficiency by utilizing machinery to handle packaging tasks, reducing human labor and minimizing errors. Semi-automatic packing systems require operator intervention for specific tasks, offering flexibility and control, while fully automatic packing systems execute the entire process independently, maximizing speed and consistency. The choice between semi-automatic and fully automatic packing depends on production volume, product complexity, and budget constraints.

What is Semi-Automatic Packing?

Semi-automatic packing involves machinery that requires human intervention to initiate or complete specific tasks, such as loading products or operating controls, while automating other steps like sealing or labeling. This method balances efficiency and flexibility, making it suitable for smaller production runs or diverse product types where full automation is cost-prohibitive. Semi-automatic packing systems improve productivity compared to manual packing by reducing labor intensity while maintaining operator oversight.

What is Fully Automatic Packing?

Fully automatic packing involves machinery that performs the entire packaging process without human intervention, enhancing efficiency and consistency in production lines. This technology integrates robotic arms, conveyors, and sensors to handle tasks such as filling, sealing, labeling, and palletizing. Fully automatic packing systems are ideal for high-volume industries like food, pharmaceuticals, and electronics, significantly reducing labor costs and minimizing errors.

Key Differences Between Semi-Automatic and Fully Automatic Packing

Semi-automatic packing requires manual intervention to load products and start the packaging process, offering greater control and flexibility but lower speed compared to fully automatic packing machines. Fully automatic packing systems integrate all stages, from feeding to sealing, enabling high-speed, continuous operation ideal for large-scale production. Your choice depends on production volume needs, labor availability, and budget constraints, making efficiency and automation level key differentiators.

Efficiency Comparison: Semi-Automatic vs Fully Automatic

Semi-automatic packing systems offer moderate efficiency by allowing some manual involvement, which can slow packaging speed and increase labor costs compared to fully automatic systems. Fully automatic packing machines maximize efficiency through continuous, high-speed operation with minimal human intervention, reducing errors and improving throughput in high-volume production environments. Your choice depends on production scale and budget, as fully automatic solutions deliver superior efficiency for large operations, while semi-automatic systems may suit smaller or flexible packaging needs.

Cost Implications and Return on Investment

Semi-automatic packing systems generally have lower initial costs compared to fully automatic packing, making them suitable for small to medium-sized operations with limited budgets. Fully automatic packing requires higher upfront investment but offers faster throughput, reduced labor costs, and increased consistency, which can lead to a quicker return on investment in high-volume production environments. Evaluating the cost implications relative to your production scale and speed requirements will help determine the most efficient packing solution for maximizing ROI.

Labor Requirements and Workforce Impact

Semi-automatic packing systems require a moderate level of labor input, as operators must manually load items and initiate the packing process, which can lead to higher workforce engagement and flexibility. Fully automatic packing systems significantly reduce labor requirements by automating the entire process, minimizing human intervention, and allowing reallocation of workforce to more skilled tasks. The workforce impact of fully automatic packing includes enhanced efficiency and potentially reduced labor costs but may require reskilling and adaptation to new technologies.

Flexibility and Scalability Considerations

Semi-automatic packing systems offer greater flexibility for handling diverse product types and adapting to varying production volumes, making them ideal for small to medium-sized operations with evolving needs. Fully automatic packing provides superior scalability for high-volume production, delivering consistent speed and efficiency but often requiring significant initial investment and less adaptability to product changes. You should evaluate your current production demands and future growth plans to determine which packing solution aligns best with your operational flexibility and scalability requirements.

Industry Applications and Suitability

Semi-automatic packing systems are ideal for small to medium-scale industries requiring flexible packaging solutions with moderate production speeds, such as artisanal food producers or local pharmaceutical companies. Fully automatic packing machines suit high-volume sectors like e-commerce, large-scale food processing, and manufacturing, where consistent speed, precision, and minimal labor intervention are crucial. Your choice depends on the balance between production capacity, budget constraints, and desired automation level in your industry application.

Choosing the Right Packing Solution for Your Business

Selecting the right packing solution depends on your business's production volume, budget, and labor resources. Semi-automatic packing machines offer flexibility and lower initial costs, ideal for small to medium-sized businesses with variable product lines. Fully automatic packing systems provide higher speed, consistency, and efficiency, making them suitable for large-scale operations aiming to maximize throughput and reduce manual labor.

Semi-Automatic Packing vs Fully Automatic Packing Infographic

libmatt.com

libmatt.com