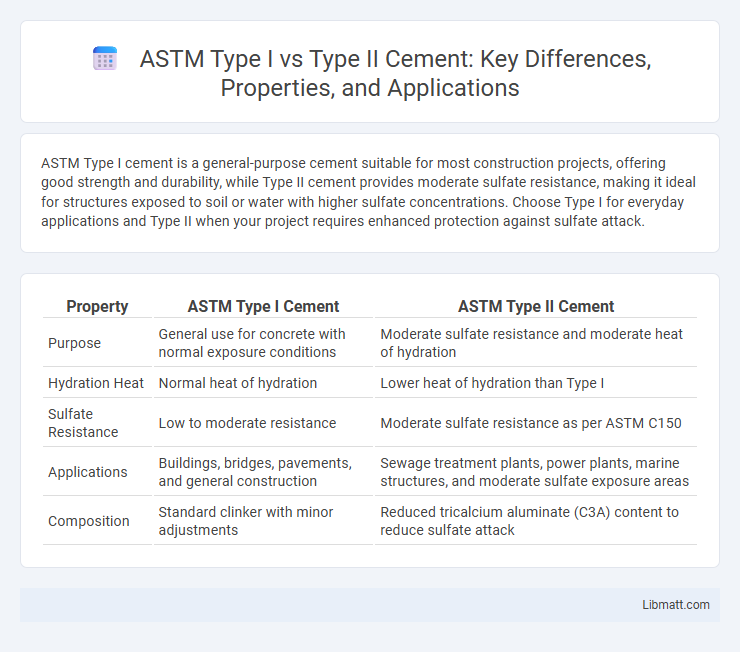

ASTM Type I cement is a general-purpose cement suitable for most construction projects, offering good strength and durability, while Type II cement provides moderate sulfate resistance, making it ideal for structures exposed to soil or water with higher sulfate concentrations. Choose Type I for everyday applications and Type II when your project requires enhanced protection against sulfate attack.

Table of Comparison

| Property | ASTM Type I Cement | ASTM Type II Cement |

|---|---|---|

| Purpose | General use for concrete with normal exposure conditions | Moderate sulfate resistance and moderate heat of hydration |

| Hydration Heat | Normal heat of hydration | Lower heat of hydration than Type I |

| Sulfate Resistance | Low to moderate resistance | Moderate sulfate resistance as per ASTM C150 |

| Applications | Buildings, bridges, pavements, and general construction | Sewage treatment plants, power plants, marine structures, and moderate sulfate exposure areas |

| Composition | Standard clinker with minor adjustments | Reduced tricalcium aluminate (C3A) content to reduce sulfate attack |

Introduction to ASTM Type I and Type II Cement

ASTM Type I cement is the standard general-purpose Portland cement used primarily for construction projects where no special properties are required. Type II cement offers moderate sulfate resistance and generates less heat during hydration, making it suitable for structures exposed to soil or groundwater with moderate sulfate concentrations. Your selection between Type I and Type II cement depends on the specific environmental conditions and durability requirements of your building project.

Overview of ASTM Cement Classifications

ASTM Type I cement is a general-purpose Portland cement suitable for most construction projects requiring normal strength and durability, while Type II cement offers moderate sulfate resistance and produces less heat during hydration, making it ideal for structures exposed to soil or water with mild sulfate content. Both classifications are defined under ASTM C150 standards, which categorize Portland cement based on chemical and physical properties tailored to specific environmental conditions and performance requirements. Selecting between Type I and Type II cement depends on factors such as exposure to sulfate environments, heat generation limits, and project specifications.

Chemical Composition Differences

ASTM Type I cement typically contains lower amounts of tricalcium aluminate (C3A) and higher proportions of tricalcium silicate (C3S), promoting faster strength gain and general use. Type II cement has moderate C3A content, reducing heat of hydration and improving sulfate resistance, ideal for structures exposed to moderate sulfate attack. Understanding these chemical composition differences helps optimize Your choice for specific construction needs.

Performance Characteristics

ASTM Type I cement exhibits high early strength and rapid setting, making it ideal for general construction and structural applications where quick turnaround is crucial. In contrast, ASTM Type II cement provides moderate sulfate resistance and lower heat of hydration, enhancing durability in environments exposed to soil or water with moderate sulfate content. Both types optimize performance based on specific environmental conditions and structural requirements, ensuring longevity and reliability in varied construction scenarios.

Sulfate Resistance Comparison

ASTM Type II cement exhibits moderate sulfate resistance, making it suitable for environments exposed to soil or water with sulfate concentrations up to 0.2%. In contrast, Type I cement offers lower sulfate resistance and is best used in general construction not subject to sulfate attack. Understanding your project's exposure to sulfates will help determine the appropriate cement type, ensuring durability and structural integrity.

Typical Applications of Type I Cement

ASTM Type I cement is commonly used in general construction projects where no special properties are required, such as residential buildings, commercial structures, sidewalks, and bridges. Its moderate heat of hydration and good mechanical strength make it ideal for applications involving reinforced concrete and precast components. Type I cement's versatility ensures reliable performance in environments with normal exposure to moisture and chemicals.

Typical Applications of Type II Cement

Type II cement is commonly used in construction projects where moderate sulfate resistance and moderate heat of hydration are required, such as in municipal structures, bridges, and sewer systems. It is suitable for environments exposed to sulfate soils or groundwater, providing better durability than Type I cement. This type of cement balances strength development with resistance to chemical attack, making it ideal for general-purpose applications that demand enhanced performance.

Environmental and Durability Considerations

ASTM Type I cement offers general purpose use with moderate resistance to sulfate attack, making it suitable for most environments but less ideal for aggressive conditions. ASTM Type II cement provides enhanced durability with moderate sulfate resistance and reduced heat of hydration, improving performance in environments exposed to moisture and chemical exposure. Choosing the right type helps optimize your structure's longevity while minimizing environmental impact through tailored material properties.

Cost and Availability Factors

ASTM Type I cement generally offers broader availability and lower cost due to its widespread use in general construction projects. Type II cement, designed for moderate sulfate resistance and lower heat of hydration, often incurs higher costs and limited availability depending on regional demand and manufacturing capabilities. Your choice between Type I and Type II cement should consider local supply constraints and budget implications to ensure efficient project management.

Choosing the Right Cement Type for Your Project

ASTM Type I cement is ideal for general construction where high early strength and moderate durability are needed, while Type II offers moderate sulfate resistance and lower heat of hydration, making it suitable for projects exposed to soil or water with sulfate content. Choosing the right cement type for your project depends on environmental factors and structural requirements to ensure durability and performance. Your selection impacts the long-term stability and strength of concrete in diverse conditions.

ASTM Type I vs Type II cement Infographic

libmatt.com

libmatt.com