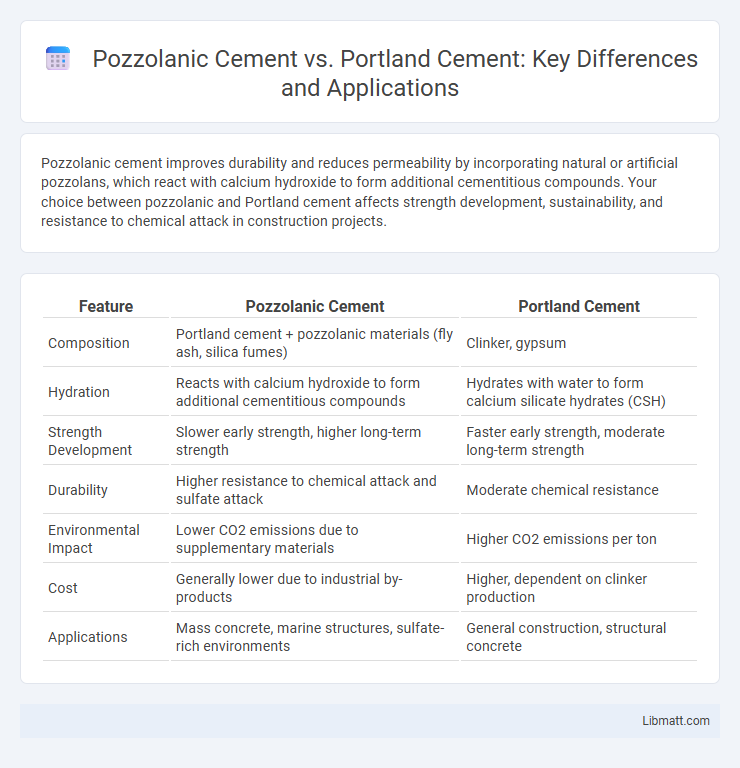

Pozzolanic cement improves durability and reduces permeability by incorporating natural or artificial pozzolans, which react with calcium hydroxide to form additional cementitious compounds. Your choice between pozzolanic and Portland cement affects strength development, sustainability, and resistance to chemical attack in construction projects.

Table of Comparison

| Feature | Pozzolanic Cement | Portland Cement |

|---|---|---|

| Composition | Portland cement + pozzolanic materials (fly ash, silica fumes) | Clinker, gypsum |

| Hydration | Reacts with calcium hydroxide to form additional cementitious compounds | Hydrates with water to form calcium silicate hydrates (CSH) |

| Strength Development | Slower early strength, higher long-term strength | Faster early strength, moderate long-term strength |

| Durability | Higher resistance to chemical attack and sulfate attack | Moderate chemical resistance |

| Environmental Impact | Lower CO2 emissions due to supplementary materials | Higher CO2 emissions per ton |

| Cost | Generally lower due to industrial by-products | Higher, dependent on clinker production |

| Applications | Mass concrete, marine structures, sulfate-rich environments | General construction, structural concrete |

Introduction to Pozzolanic and Portland Cement

Pozzolanic cement is a blend of ordinary Portland cement and pozzolanic materials such as fly ash, silica fume, or volcanic ash, which enhance durability and reduce permeability by reacting with calcium hydroxide in concrete. Portland cement is the most commonly used hydraulic cement composed primarily of clinker (calcium silicates) ground with gypsum, known for its high early strength and versatility in construction. The key difference lies in pozzolanic cement's improved resistance to chemical attacks and environmental degradation due to the supplementary cementitious materials incorporated.

Chemical Composition Differences

Pozzolanic cement contains a significant amount of pozzolanic materials such as fly ash, volcanic ash, or silica fumes, which react with calcium hydroxide to form additional cementitious compounds, enhancing durability and reducing permeability. Portland cement primarily consists of clinker phases like tricalcium silicate (C3S), dicalcium silicate (C2S), tricalcium aluminate (C3A), and tetracalcium aluminoferrite (C4AF), with limited secondary additives. Your project benefits from understanding that pozzolanic cement's lower calcium oxide content and increased siliceous and aluminous compounds result in improved sulfate resistance and reduced heat of hydration compared to conventional Portland cement.

Manufacturing Process Comparison

Pozzolanic cement is produced by blending Portland cement clinker with natural or artificial pozzolanic materials such as fly ash, silica fume, or volcanic ash, which enhances its chemical reactivity and durability. Portland cement manufacturing involves the calcination of limestone and clay at high temperatures to form clinker, which is then ground into a fine powder without the inclusion of supplementary materials. The integration of pozzolanic materials in pozzolanic cement requires additional grinding and mixing processes, contributing to improved long-term strength and resistance to chemical attacks compared to standard Portland cement.

Key Physical Properties

Pozzolanic cement exhibits enhanced durability and reduced permeability due to its finely divided pozzolanic materials that react with calcium hydroxide, improving resistance to chemical attacks. Portland cement typically has higher early strength but can be more susceptible to sulfate attack and thermal cracking compared to pozzolanic blends. The particle size distribution and hydration rate in pozzolanic cement contribute to lower heat of hydration and improved long-term strength development.

Strength and Durability Performance

Pozzolanic cement exhibits enhanced long-term strength and durability compared to Portland cement due to its ability to react with calcium hydroxide, forming additional calcium silicate hydrate (C-S-H) that densifies the microstructure. This pozzolanic reaction reduces permeability and increases resistance to chemical attacks like sulfate and chloride ingress, prolonging the lifespan of concrete structures. While Portland cement offers high early strength, pozzolanic cement provides superior performance in aggressive environments and sustained load-bearing applications.

Environmental Impact and Sustainability

Pozzolanic cement significantly reduces carbon emissions by incorporating natural or industrial pozzolans, which lowers the amount of Portland cement clinker required in the mix, thus decreasing your project's overall environmental footprint. This cement type enhances sustainability by utilizing waste materials such as fly ash or volcanic ash, contributing to resource conservation and reducing landfill waste. Portland cement production generates higher CO2 emissions and energy consumption, making pozzolanic cement a more eco-friendly choice for sustainable construction.

Cost and Availability Factors

Pozzolanic cement typically costs less than Portland cement due to the use of naturally abundant materials like fly ash or volcanic ash, which reduce reliance on costly clinker production. Availability depends on local resources; areas rich in pozzolanic materials can supply this cement more easily, while Portland cement remains widely available worldwide. Your choice between the two will depend on balancing cost savings with local material access and construction requirements.

Common Applications in Construction

Pozzolanic cement is widely used in marine structures, dams, and foundations due to its superior resistance to chemical attack and enhanced durability in harsh environmental conditions. Portland cement is commonly applied in general construction projects such as residential buildings, pavements, and bridges because of its fast setting time and high early strength. Your choice between pozzolanic and Portland cement should consider specific project requirements and exposure conditions to ensure optimal performance and longevity.

Advantages and Limitations of Each Type

Pozzolanic cement offers enhanced durability and resistance to chemical attacks due to its reactive silica content, making it ideal for marine and sulfate-rich environments, but it generally requires longer curing times compared to Portland cement. Portland cement provides rapid strength development and is widely available, making it suitable for general construction, though it can be more susceptible to cracking and chemical degradation over time. Your choice should consider project-specific needs such as strength requirements, environmental exposure, and curing time constraints.

How to Choose the Right Cement for Your Project

Selecting the right cement for your project depends on factors such as durability requirements, environmental impact, and project scale. Pozzolanic cement offers enhanced resistance to chemical attacks and reduced permeability, making it ideal for marine or sewage structures, while Portland cement provides high early strength suitable for general construction and quick setting. Considering project-specific needs, including exposure conditions and sustainability goals, helps determine whether the longevity benefits of pozzolanic cement or the fast strength gain of Portland cement is more appropriate.

Pozzolanic Cement vs Portland Cement Infographic

libmatt.com

libmatt.com