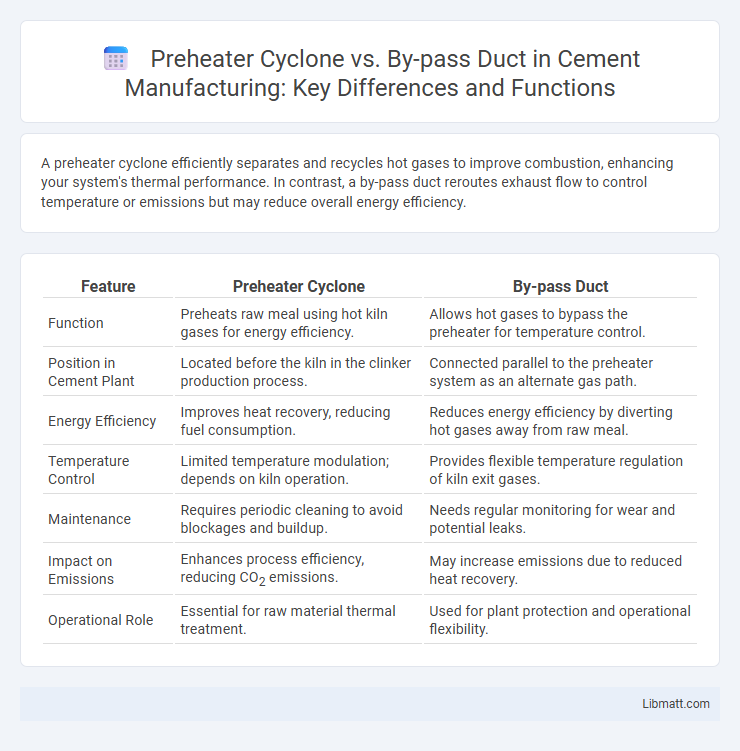

A preheater cyclone efficiently separates and recycles hot gases to improve combustion, enhancing your system's thermal performance. In contrast, a by-pass duct reroutes exhaust flow to control temperature or emissions but may reduce overall energy efficiency.

Table of Comparison

| Feature | Preheater Cyclone | By-pass Duct |

|---|---|---|

| Function | Preheats raw meal using hot kiln gases for energy efficiency. | Allows hot gases to bypass the preheater for temperature control. |

| Position in Cement Plant | Located before the kiln in the clinker production process. | Connected parallel to the preheater system as an alternate gas path. |

| Energy Efficiency | Improves heat recovery, reducing fuel consumption. | Reduces energy efficiency by diverting hot gases away from raw meal. |

| Temperature Control | Limited temperature modulation; depends on kiln operation. | Provides flexible temperature regulation of kiln exit gases. |

| Maintenance | Requires periodic cleaning to avoid blockages and buildup. | Needs regular monitoring for wear and potential leaks. |

| Impact on Emissions | Enhances process efficiency, reducing CO2 emissions. | May increase emissions due to reduced heat recovery. |

| Operational Role | Essential for raw material thermal treatment. | Used for plant protection and operational flexibility. |

Introduction to Preheater Cyclone and By-pass Duct

Preheater Cyclones enhance energy efficiency by utilizing hot gases from the kiln to preheat raw materials in cement production, improving the thermal process. By-pass Ducts serve as alternative pathways for gases to avoid cyclones, used during kiln shutdowns or operational issues to maintain system stability. Both components play critical roles in optimizing kiln operation and energy consumption in cement manufacturing.

Overview of Cement Plant Gas Flow Systems

Preheater cyclone and by-pass duct are critical components in cement plant gas flow systems that manage kiln and preheater exhaust gases for efficient heat recovery and emission control. The preheater cyclone system captures hot gases from the kiln, enabling raw material heating through staged cyclones, enhancing thermal efficiency and reducing fuel consumption. By-pass ducts provide an alternative pathway to divert gases during maintenance or abnormal conditions, preventing process disruptions and protecting equipment from thermal damage.

Working Principle of Preheater Cyclones

Preheater cyclones operate by directing hot gases and raw meal into a circular chamber where centrifugal force separates solid particles from the gas stream, ensuring efficient heat transfer and drying of the raw materials before kiln entry. This process enhances fuel efficiency and reduces emissions in cement manufacturing. Understanding the working principle of preheater cyclones can help optimize your plant's thermal performance and overall production quality.

Function and Design of By-pass Ducts

By-pass ducts in preheater systems function to divert kiln exhaust gases away from the main preheater tower during startup, shutdown, or abnormal operation, protecting the equipment from thermal stress. Their design includes robust, heat-resistant materials and adjustable dampers to control gas flow, ensuring optimal temperature regulation and operational safety. By-pass ducts facilitate continuous kiln operation while preventing damage to the preheater cyclone and ensuring efficient heat recovery.

Key Differences Between Preheater Cyclone and By-pass Duct

Preheater cyclones and by-pass ducts serve distinct functions in cement kiln systems, with preheater cyclones primarily designed to recover heat by facilitating raw meal preheating through multi-stage cyclonic separation, enhancing energy efficiency. By-pass ducts, however, provide an alternate pathway for gases to circumvent the preheater or kiln, enabling temperature control and maintenance without disrupting operation. Understanding these key differences helps optimize your kiln performance and maintain process stability under varying operational conditions.

Impact on Kiln Efficiency

Preheater cyclones significantly enhance kiln efficiency by facilitating better heat exchange and reducing fuel consumption through effective preheating of raw materials. In contrast, by-pass ducts decrease overall efficiency by diverting hot gases away from the preheater system, leading to heat losses and incomplete energy recovery. Optimal kiln operation relies on maximizing cyclone effectiveness while minimizing the use of by-pass ducts to sustain thermal performance and reduce fuel costs.

Influence on Energy Consumption

Preheater cyclones optimize energy consumption by enhancing heat transfer efficiency through multistage gas-solid contact, reducing the fuel required for clinker production. In contrast, by-pass ducts divert hot gases away, potentially lowering the system's thermal efficiency and increasing energy consumption. Your kiln system benefits more from preheater cyclones due to their ability to retain and utilize heat within the process stream effectively.

Effects on Emissions and Environmental Compliance

Preheater cyclones enhance combustion efficiency by improving air and fuel mixing, leading to lower NOx and CO emissions, thereby supporting stringent environmental compliance. By-pass ducts, while allowing flexibility in operation by diverting gases around the preheater, can increase particulate and unburned hydrocarbon emissions due to incomplete combustion. Optimizing the balance between preheater cyclone usage and by-pass duct operation is critical to minimizing environmental impact and meeting regulatory emission standards.

Maintenance and Operational Considerations

Maintenance of a Preheater Cyclone involves regular inspections for wear and erosion due to high temperatures and abrasive materials, ensuring optimal airflow and dust separation efficiency. By-pass Duct systems require frequent monitoring and cleaning to prevent blockages and manage temperature fluctuations that can impact cement quality and kiln performance. Your choice depends on balancing maintenance accessibility with operational stability to minimize downtime and optimize overall plant productivity.

Conclusion: Choosing the Right System

Selecting the right system between a Preheater Cyclone and a By-pass Duct depends on operational efficiency, maintenance needs, and cost-effectiveness. Preheater Cyclones enhance heat exchange and fuel efficiency by recycling hot gases, while By-pass Ducts provide flexibility to control temperatures and reduce thermal stress during kiln startup or shutdown. Optimizing system choice involves balancing process stability, energy savings, and equipment longevity for cement production.

Preheater Cyclone vs By-pass Duct Infographic

libmatt.com

libmatt.com