Fineness measures the average particle size of a material, while Specific Surface Area quantifies the total surface area per unit mass, directly influencing reactivity and strength in cementitious materials. Optimizing your project's performance requires understanding both properties, as higher specific surface area typically enhances hydration rates despite similar fineness values.

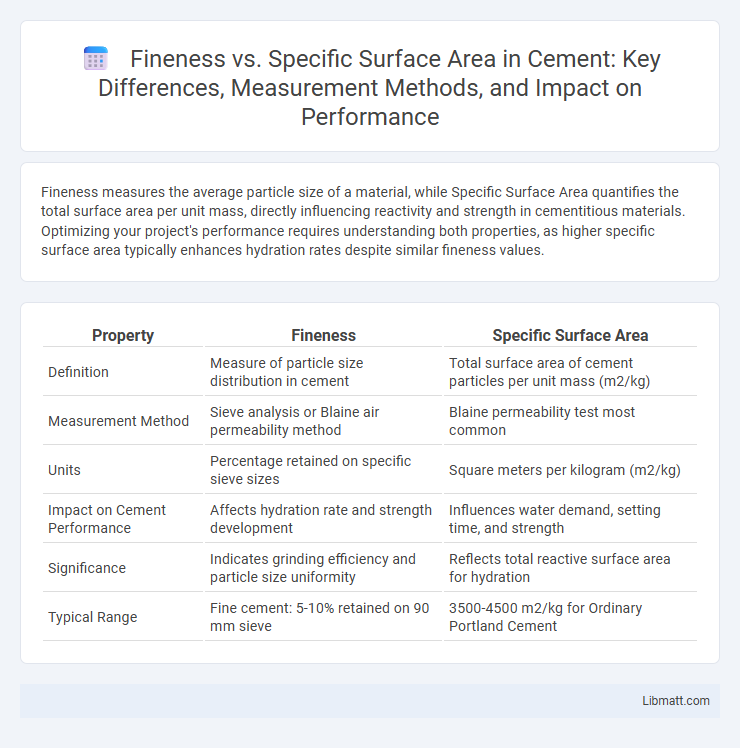

Table of Comparison

| Property | Fineness | Specific Surface Area |

|---|---|---|

| Definition | Measure of particle size distribution in cement | Total surface area of cement particles per unit mass (m2/kg) |

| Measurement Method | Sieve analysis or Blaine air permeability method | Blaine permeability test most common |

| Units | Percentage retained on specific sieve sizes | Square meters per kilogram (m2/kg) |

| Impact on Cement Performance | Affects hydration rate and strength development | Influences water demand, setting time, and strength |

| Significance | Indicates grinding efficiency and particle size uniformity | Reflects total reactive surface area for hydration |

| Typical Range | Fine cement: 5-10% retained on 90 mm sieve | 3500-4500 m2/kg for Ordinary Portland Cement |

Introduction to Fineness and Specific Surface Area

Fineness measures the particle size distribution of materials like cement, affecting hydration rate and strength development. Specific surface area quantifies the total surface area per unit mass, influencing reaction kinetics and material performance. Both parameters are critical in determining the quality and behavior of powdered substances in construction and material science.

Defining Fineness in Material Science

Fineness in material science refers to the measure of particle size distribution within a powdered material, indicating how finely the particles are divided. It directly influences specific surface area, which quantifies the total surface area per unit mass or volume, affecting reactivity and strength in materials like cement and catalysts. Accurate fineness assessment ensures optimal performance by controlling surface-related properties in industrial applications.

Understanding Specific Surface Area

Understanding specific surface area is crucial as it measures the total surface area of particles per unit mass or volume, directly influencing material reactivity and strength in various applications. Unlike fineness, which only describes particle size, specific surface area accounts for particle shape and porosity, providing a more detailed parameter for predicting performance. Your knowledge of specific surface area helps optimize processes in industries like cement production, pharmaceuticals, and catalysis.

Key Differences Between Fineness and Specific Surface Area

Fineness primarily measures the particle size distribution or average particle diameter, often expressed in microns or by sieve analysis, whereas Specific Surface Area quantifies the total surface area per unit mass, typically measured in square meters per gram (m2/g) using techniques like BET analysis. Fineness impacts properties such as flowability and packing density, while Specific Surface Area influences reactivity, hydration rate, and strength development in materials. Understanding these distinctions helps you optimize material performance in cement, powders, and catalysts by selecting appropriate measurement parameters for quality control and process improvement.

Measurement Methods for Fineness

Fineness of powders is primarily measured using methods such as sieve analysis, air permeability tests (Blaine method), and laser diffraction, each providing quantifiable particle size distributions. Sieve analysis categorizes particles by size through a stack of meshes, while the Blaine air permeability method estimates fineness by measuring airflow resistance through a compacted sample. Laser diffraction accurately calculates specific surface area and particle size by analyzing light scattering patterns, offering detailed fineness data for diverse materials.

Techniques for Measuring Specific Surface Area

Techniques for measuring specific surface area include the Brunauer-Emmett-Teller (BET) method, which uses gas adsorption to determine surface area with high accuracy. Mercury intrusion porosimetry and laser diffraction are alternative approaches that assess particle size distribution and porosity, indirectly estimating surface characteristics. Understanding these methods helps you select appropriate analysis techniques for materials requiring precise characterization of fineness and surface properties.

Impact of Fineness on Material Properties

Fineness significantly influences the specific surface area of materials, directly affecting reactivity and strength development in cementitious composites. Higher fineness increases the specific surface area, enhancing hydration rates and improving the mechanical properties of concrete. This leads to faster setting times and greater early-age strength but may also increase water demand and affect workability.

Role of Specific Surface Area in Performance

Specific surface area significantly influences material performance by enhancing reactivity and interaction with surrounding substances, especially in catalysis and adsorption processes. High specific surface area improves the efficiency of catalysts by providing more active sites for chemical reactions, directly impacting product yield and reaction rates. In contrast, fineness alone, typically measured by particle size, does not fully capture these interactive properties, making specific surface area a more critical parameter for performance optimization.

Comparative Applications in Industry

Fineness and Specific Surface Area (SSA) are critical parameters in industries such as cement manufacturing, pharmaceuticals, and pigments, where particle size influences activity and performance. Fineness typically refers to the particle size distribution, impacting setting time and strength in cement, while SSA measures the total surface area per unit mass, affecting reaction rates and adsorption capacity in catalysts and drug formulations. Your choice between fineness and SSA depends on industry-specific requirements, with SSA offering greater insight into surface-related properties essential for chemical reactivity and material efficiency.

Summary: Choosing Between Fineness and Specific Surface Area

Choosing between fineness and specific surface area depends on the application requirements and material characteristics. Fineness measures particle size distribution, affecting hydration and strength development in cement, while specific surface area quantifies the total exposed surface impacting reaction rates and workability. Your decision should balance these properties to optimize performance and durability in construction materials.

Fineness vs Specific Surface Area Infographic

libmatt.com

libmatt.com